How Does an Air Compressor Work? A Deep Dive

Table of Contents

- Introduction

- The Unseen Force: Boyle's Law in Action

- Anatomy of an Industrial Air Compressor

- Two Dominant Technologies: How Compression is Achieved

- Selecting the Right Compressor: Key Metrics for Procurement

- The Maden.co Advantage: Reshoring Your Procurement Strategy

- Conclusion

- Frequently Asked Questions

Introduction

Imagine the rhythmic pulse of a modern American factory floor suddenly falling silent. Production lines halt, pneumatic tools go limp, and a costly wave of unplanned downtime begins to spread. The culprit? Not a complex robotics failure or a software glitch, but the shutdown of a single, crucial piece of equipment: the industrial air compressor. This scenario, all too familiar to plant managers and MRO buyers, underscores a fundamental truth of modern industry: compressed air is the fourth utility, as vital as electricity, water, and natural gas. Yet, its source is often one of the most misunderstood machines in the facility.

This article is designed to change that. We will move beyond a surface-level explanation to provide a detailed mechanical breakdown of how air compressors function. We will explore the core scientific principles, dissect the key components, and compare the dominant technologies—from reciprocating pistons to advanced rotary screws. More importantly, we will connect this technical knowledge to the practical realities of procurement, helping you understand how to select the right equipment to enhance operational efficiency, reduce total cost of ownership, and strengthen your supply chain. For any business reliant on pneumatic power, understanding the inner workings of an air compressor isn't just an academic exercise; it's a critical step toward building a more resilient, productive, and competitive American manufacturing operation.

The Unseen Force: Boyle's Law in Action

At its heart, every air compressor, regardless of its size or complexity, operates on a simple, elegant principle of physics discovered in the 17th century: Boyle's Law. This law states that for a fixed mass of gas at a constant temperature, the pressure and volume are inversely proportional. In simpler terms, if you decrease the volume of a container holding air, the pressure of that air will increase.

This is the foundational concept of air compression. An air compressor is essentially a machine engineered to perform this task with relentless efficiency:

- Intake: The process begins by drawing in ambient air from the surrounding environment.

- Volume Reduction: The machine then forces this air into a progressively smaller space. This is the "work" phase, where the motor's energy is transferred to the air.

- Pressure Increase: As the volume decreases, the air molecules are packed closer together, causing more frequent collisions with each other and the walls of their container. This increased molecular activity is what we measure as pressure.

- Discharge: Finally, this highly pressurized air is discharged and stored in a receiver tank, ready to be used to power tools, actuate cylinders, or perform countless other industrial tasks.

The energy expended by the compressor's motor is converted into the potential energy stored within the compressed air. When that air is released to power a tool, this potential energy is converted back into kinetic energy, performing useful work. Understanding this fundamental energy transfer is key to appreciating the efficiency differences between various compressor technologies.

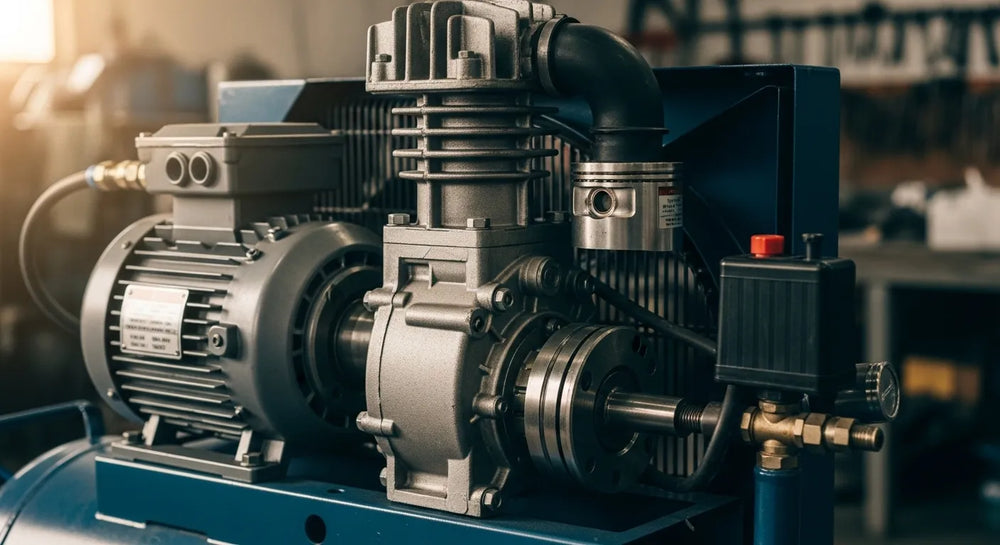

Anatomy of an Industrial Air Compressor

While designs vary, nearly all industrial air compressors are built from a common set of core components. For a procurement manager or engineer, knowing these parts and their functions is essential for diagnosing issues, specifying requirements, and understanding maintenance needs.

The Power Source: Motor or Engine

This is the prime mover, providing the rotational force needed to drive the compression mechanism. In most industrial settings, this is an electric motor, valued for its reliability, efficiency, and ease of integration. The motor's horsepower (HP) or kilowatt (kW) rating is a primary indicator of the compressor's potential output capacity.

The Compression Mechanism: The Heart of the Machine

This is where the magic of Boyle's Law happens. It's the assembly that physically reduces the air's volume. The design of this mechanism is the main factor that differentiates compressor types, such as reciprocating pistons, rotary screws, or centrifugal impellers. We will explore these in detail later.

Air Inlet and Filtration System

Before air can be compressed, it must be drawn into the machine. The inlet valve controls this flow, while a critical series of filters removes dust, pollen, and other airborne particulates. Clean intake air is paramount; contaminants can cause premature wear on internal components, reduce efficiency, and compromise the quality of the final compressed air output.

The Storage Tank (Receiver)

The large, cylindrical tank attached to most stationary compressors is the receiver. It serves several vital functions:

- Stores Pressurized Air: It acts as a buffer, providing a ready supply of compressed air to meet sudden, high-volume demands without forcing the compressor to cycle on and off constantly.

- Dampens Pulsations: For piston-style compressors, which deliver air in pulses, the tank smooths out the flow, providing a consistent output pressure.

- Aids in Cooling: It provides a large surface area, allowing the hot compressed air to cool slightly, which causes some of the entrained water vapor to condense.

Drain Valves

As air is compressed, its temperature rises dramatically. When it subsequently cools in the receiver tank, any water vapor it contains condenses into liquid water, or condensate. This moisture is corrosive and can damage pneumatic tools and processes. Drain valves, which can be manual or automatic, are installed on the receiver tank to purge this accumulated water.

Control System: Pressure Switch and Regulator

The control system is the brain of the compressor. The pressure switch is a sensor that monitors the pressure inside the receiver tank. It tells the motor when to start (at a pre-set "cut-in" pressure) and when to stop (at the "cut-out" pressure). The regulator, typically located at the outlet, allows the user to dial in the precise pressure required for a specific application, which may be lower than the pressure stored in the tank.

Two Dominant Technologies: How Compression is Achieved

The method used to reduce the air's volume defines the compressor's category. In the industrial world, nearly all compressors fall into one of two main families: Positive Displacement or Dynamic.

Positive Displacement Compressors

This is the most common category. These machines work by trapping a specific volume of air in a chamber and then physically reducing the volume of that chamber to increase the pressure.

Reciprocating (Piston) Compressors

The classic and most recognizable type, a reciprocating compressor functions much like the internal combustion engine in a car.

- A crankshaft, driven by the motor, moves a piston up and down within a cylinder.

- On the downstroke, the inlet valve opens, and ambient air is drawn into the cylinder.

- On the upstroke, the inlet valve closes, and the piston moves upward, compressing the trapped air.

- Once the pressure reaches a certain point, the discharge valve opens, sending the pressurized air to the receiver tank.

This cycle repeats rapidly. Single-stage compressors compress the air in a single piston stroke. Two-stage compressors use a larger, low-pressure piston to perform the initial compression, then send that moderately pressurized air to a smaller, high-pressure piston for the final compression. This two-step process is more efficient and generates less heat for pressures above 100 PSI.

While cost-effective for smaller workshops and intermittent use, their high number of moving parts results in more wear, higher maintenance, and louder operation.

Rotary Screw Compressors

For demanding, continuous-duty industrial applications, the rotary screw compressor is the undisputed workhorse. This design offers superior efficiency, lower noise levels, and unmatched reliability for operations that run around the clock.

Inside a rotary screw compressor, there is no piston. Instead, two large, intermeshing helical screws (rotors) spin in opposite directions within a tight-fitting housing.

- Air is drawn in at one end and fills the space in the grooves between the rotors.

- As the screws turn, the air is trapped in these grooves and pushed along the length of the housing.

- The geometry of the screws is such that the volume of these trapped pockets of air progressively decreases.

- This reduction in volume compresses the air, which is then discharged at the opposite end.

Because the process is continuous and smooth, with no pistons stopping and changing direction, rotary screw compressors can run 100% of the time without issue. They deliver a steady, non-pulsating flow of air and are significantly quieter and more energy-efficient for high-volume needs.

Dynamic (Centrifugal) Compressors

Less common except in massive-scale industrial settings (like petrochemical plants or steel mills), dynamic compressors work on a different principle. Instead of trapping and squeezing air, they use a rapidly spinning impeller to accelerate the air to a very high velocity. This fast-moving air is then forced through a diffuser, which slows it down. As the air decelerates, its kinetic energy is converted into potential energy in the form of pressure. They are designed for extremely high airflows but are not typically found in general manufacturing or MRO applications.

Selecting the Right Compressor: Key Metrics for Procurement

Understanding the mechanics is the first step. The second is translating that knowledge into a smart procurement decision. An oversized compressor wastes enormous amounts of energy, while an undersized one will lead to production bottlenecks and tool failure.

PSI vs. CFM: Pressure and Volume

These are the two most important specifications for any compressor.

- PSI (Pounds per Square Inch): This measures the force or pressure the compressor can deliver. Most pneumatic tools require around 90-100 PSI to operate correctly. The compressor must be able to meet the highest pressure requirement of any tool on the line.

- CFM (Cubic Feet per Minute): This measures the volume of air the compressor can deliver at a specific pressure. To determine your CFM requirement, you must add up the CFM ratings of all tools and equipment that will be operating simultaneously, then add a buffer of 25-30% for future growth and potential leaks.

A common mistake is buying a compressor based only on horsepower. Always specify your needs in terms of required CFM at a required PSI. This is the language of performance.

Duty Cycle: The Marathon vs. The Sprint

Duty cycle refers to the percentage of time a compressor can run within a given period without overheating. A piston compressor might have a 50% or 75% duty cycle, meaning it needs to rest for a portion of every hour. A rotary screw compressor, by design, has a 100% duty cycle, meaning it is built to run continuously, 24/7, if needed. For a production line that never stops, a 100% duty cycle machine isn't a luxury; it's a requirement.

Fixed Speed vs. Variable Speed Drive (VSD): A TCO Game-Changer

This is one of the most critical decisions for a modern industrial buyer, directly impacting the Total Cost of Ownership (TCO) of the equipment.

-

Fixed Speed Compressors: These are the traditional design. When the motor is on, it runs at 100% speed and power, producing the compressor's maximum rated CFM. When the tank pressure is met, the motor shuts off (or unloads). This is highly efficient if your air demand is constant and consistently high. For an operation with a predictable, steady air load, a robust, American-made unit like the Gardner Denver ESM 29 Fixed Speed Air Compressor offers an excellent balance of performance, reliability, and upfront value. It's a testament to industrial excellence built for consistent workloads.

-

Variable Speed Drive (VSD) Compressors: These machines represent a significant leap in efficiency. A VSD compressor uses advanced electronics to adjust the speed of its motor to precisely match the real-time air demand of the facility. If the demand drops by 30%, the motor slows down, consuming significantly less energy. For facilities with fluctuating air demand—common in multi-shift operations with varying processes—a VSD compressor can slash energy costs by 30-50%. The initial investment is higher, but the return on investment through energy savings is often realized in just a few years.

For a procurement manager tasked with reducing long-term operational costs, specifying a VSD unit is a strategic move. A powerful and efficient option like the Gardner Denver 75 kW Variable Speed Rotary Screw Air Compressor provides this smart technology, made right here in the U.S. For even larger-scale operations where peak efficiency is paramount, the Gardner Denver VST Series Two-Stage Variable Speed Air Compressor combines the efficiency of a two-stage design with the intelligence of VSD, representing the pinnacle of compressed air technology.

The Maden.co Advantage: Reshoring Your Procurement Strategy

In today's volatile global landscape, the hidden costs of international sourcing—from shipping delays and tariffs to quality control issues—are becoming increasingly apparent. Choosing the right air compressor is not just about specs; it's about securing a reliable, long-term asset for your operation. This is where sourcing from verified American manufacturers becomes a powerful competitive advantage.

At Maden.co, our entire business model is built on this principle. We are committed to democratizing access to American manufacturing, connecting industrial buyers with a vast catalog of over 2.5 million products from our network of 800+ vetted U.S. manufacturers. Our mission is to prove that sourcing American-made components can be as convenient and efficient as any global alternative, fueling the nation's manufacturing revival. You can learn more about our mission to champion American manufacturing here.

This commitment provides tangible benefits:

- Supply Chain Transparency and Resilience: By sourcing domestically, you shorten your supply chain, reduce lead times, and gain clarity on where your critical equipment is made.

- Industrial Excellence: You gain access to products built to rigorous U.S. standards, ensuring quality, reliability, and readily available support.

- Customer Empowerment: We eliminate procurement friction. Our platform provides the detailed technical data engineers need and the streamlined purchasing process that buyers demand. For capital-intensive purchases like a new compressor, this empowerment extends to finances. You can apply for Instant Financing at checkout to manage cash flow and acquire the right equipment without delaying critical projects.

This commitment to a robust domestic supply chain is a two-way street. We are constantly expanding our network of partners. Are you a U.S. manufacturer? Register as a vendor and join the American manufacturing revival.

If you have specific questions about compressor selection or need help navigating our catalog, our team of experts is ready to assist. Please contact us for personalized support.

Conclusion

An air compressor is far more than a simple motor and a tank. It is a sophisticated machine that transforms electrical energy into the powerful and versatile utility of compressed air. From the fundamental physics of Boyle's Law to the intricate mechanics of rotary screws and the intelligent control of variable speed drives, understanding how it works empowers you to make smarter decisions.

Choosing the right technology—be it a cost-effective fixed-speed unit for steady demand or a high-efficiency VSD model for fluctuating loads—can have a profound impact on your company's productivity and bottom line. By prioritizing this technical knowledge and partnering with a platform dedicated to American manufacturing, you are not just buying a machine. You are investing in your facility's efficiency, strengthening your supply chain's resilience, and contributing to the revitalization of America's industrial base.

Explore our comprehensive catalog of U.S.-made air compressors and pneumatic components today. Find the exact solution for your operational needs and take advantage of Instant Financing at checkout to make your next strategic investment simple and affordable.

Frequently Asked Questions

1. What is the difference between single-stage and two-stage compressors?

A single-stage compressor compresses the air in one continuous stroke of a single piston, typically reaching pressures around 125-135 PSI. A two-stage compressor uses two pistons: a larger, low-pressure piston performs the first stage of compression, and the air is then cooled before being sent to a smaller, high-pressure piston for the final compression, efficiently reaching pressures of 175 PSI or higher. Two-stage models are more energy-efficient and run cooler for high-pressure, continuous-use applications.

2. How do I determine the right size (CFM) compressor for my needs?

To correctly size a compressor, first list all the tools and equipment that will use compressed air. Find the CFM requirement for each tool (usually stamped on the tool or found in its manual). Add the CFM ratings for all tools that will be running at the same time. Finally, add a "buffer" of at least 25-30% to this total. This buffer accounts for future growth, potential air leaks in the system, and ensures the compressor isn't constantly running at its absolute maximum capacity.

3. Why is moisture a problem in compressed air lines?

When air is compressed, it heats up, and its ability to hold water vapor decreases. As the air cools in the receiver tank and travels through the pipes, this excess vapor condenses into liquid water. This water can cause rust and corrosion inside pipes, pneumatic tools, and machinery. It can also wash away lubricants in air tools, leading to premature failure, and can ruin paint finishes or contaminate products in manufacturing processes. This is why air dryers and in-line filters are essential components of a compressed air system.

4. Is a variable speed drive (VSD) compressor always better?

Not necessarily. A VSD compressor is exceptionally energy-efficient for applications with fluctuating or variable air demand. By matching its motor speed to the real-time air usage, it avoids the energy waste associated with running a fixed-speed motor in a loaded/unloaded cycle. However, if your facility has a very stable, consistent air demand that keeps a compressor running at or near its full capacity most of the time, a high-quality fixed-speed compressor can be a more cost-effective choice in terms of initial capital investment and may offer comparable energy efficiency in that specific scenario. The choice depends entirely on your demand profile.