How Long Does an Industrial AC Compressor Last?

Table of Contents

- Introduction

- The Industrial Compressor: An Operational Centerpiece

- The Baseline Lifespan: What the Numbers Suggest

- Critical Factors Influencing Compressor Longevity

- The Proactive MRO Strategy: A Maintenance Deep Dive

- Recognizing the Signs: Early Warnings of Compressor Failure

- Sourcing Your Replacement: The Maden.co Advantage

- For U.S. Manufacturers: Join the Revival

- Conclusion

- Frequently Asked Questions (FAQ)

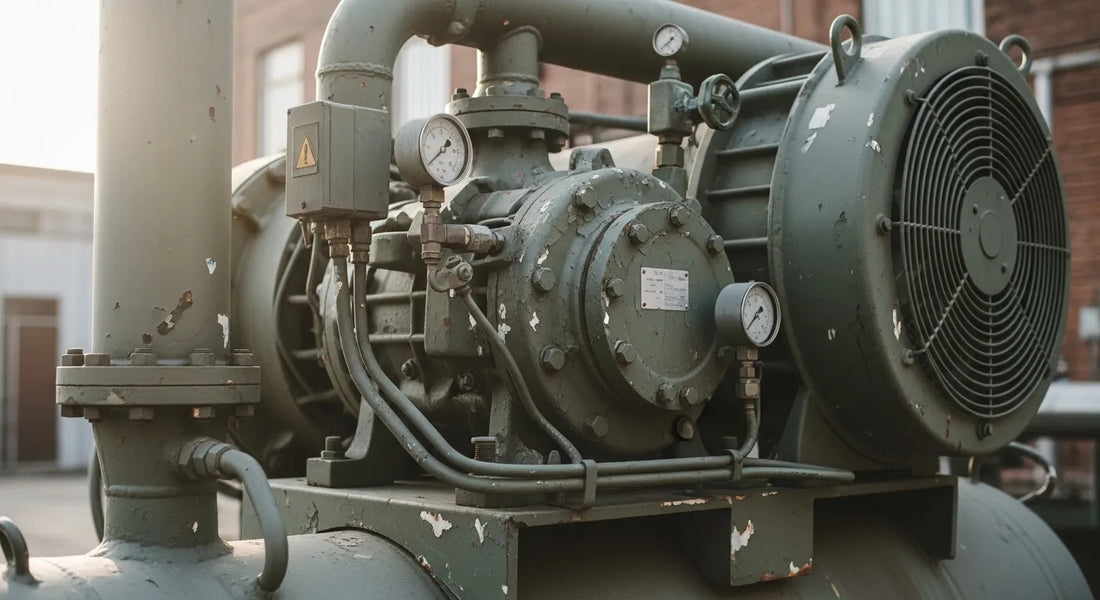

Introduction

A sudden, high-pitched metallic shriek echoes across the factory floor, followed by an unnerving silence. The plant's main compressed air system, the heart of both the production line and the large-scale HVAC that keeps critical equipment cool, has just gone down. For the Maintenance, Repair, and Operations (MRO) manager on duty, this isn't just an inconvenience; it's the start of a costly race against the clock. Every minute of downtime translates to lost production, delayed shipments, and mounting operational pressure. This scenario is a stark reality in industrial settings, and at its center is often a single, overworked component: the air compressor. While often discussed in residential terms, the question of "how long should an air conditioner compressor last?" takes on a far more critical meaning in the industrial world, where its failure can bring an entire operation to a standstill.

This article moves beyond residential estimates to provide a definitive resource for procurement managers, engineers, and business owners. We will dissect the true lifespan of industrial-grade air compressors—the workhorses behind everything from large-scale climate control to pneumatic tool operation. We will explore the key factors that dictate their longevity, from initial manufacturing quality to daily operating conditions and maintenance protocols. Furthermore, we will identify the early warning signs of impending failure and outline a strategic approach to sourcing reliable, long-lasting replacements. Our goal is to empower you with the knowledge to not only predict and extend the life of your current equipment but also to build a more resilient and efficient supply chain. At Maden.co, we believe that understanding the lifecycle of critical components is the first step toward achieving operational excellence, a principle that drives our commitment to connecting buyers with America's best manufacturers.

The Industrial Compressor: An Operational Centerpiece

Before we can accurately discuss lifespan, it's crucial to differentiate between the small, sealed compressor in a home AC unit and the robust, serviceable machines used in industrial applications. While both operate on similar principles of pressurizing a gas or refrigerant, their design, scale, and operational demands are worlds apart.

An industrial air compressor is the power source for a vast array of processes:

- Pneumatic Systems: Driving actuators, tools, and machinery on assembly lines.

- Climate Control (HVAC): Serving as the core of large-scale chillers and air conditioning systems that cool entire facilities, data centers, and manufacturing floors.

- Material Handling: Powering conveyors, lifts, and sorting systems.

- Process Applications: Providing clean, dry air for painting, sandblasting, and food and beverage packaging.

Given this central role, its reliability is non-negotiable. The lifespan isn't just a matter of comfort; it's a matter of production uptime, product quality, and workplace safety. This is why our entire business model is built on ensuring access to components that meet the highest standards of industrial excellence; you can learn more about our mission to champion American manufacturing here.

Types of Industrial Compressors and Their Lifespan Implications

The type of compressor technology employed has a direct and significant impact on its expected service life, especially when matched correctly to its application.

-

Reciprocating (Piston) Compressors: These are the classic workhorses, using pistons to compress air. They are excellent for applications requiring high pressure but intermittent use. Because they have more moving parts that experience friction, their lifespan in continuous-duty applications can be shorter. However, for workshops or operations with fluctuating demand, a well-maintained reciprocating compressor offers exceptional value. A robust example is the Champion® R and PL Series 5 HP Oil-Lubricated Air Compressor, designed for durability in demanding service environments.

-

Rotary Screw Compressors: These compressors use two intermeshing helical screws to compress air. They are designed for 100% continuous duty cycles, making them the standard for manufacturing plants and facilities that require a constant supply of air. With fewer wearing parts and integrated cooling systems, they generally have a much longer operational lifespan than reciprocating models when used as intended. The Gardner Denver ESM 75 Fixed Speed Screw Air Compressor exemplifies this design, engineered for reliability and energy efficiency in continuous industrial use.

-

Centrifugal Compressors: Used in very large-scale industrial applications, these dynamic compressors use a rotating impeller to accelerate air, which is then slowed to build pressure. They offer extremely high flow rates and are built for decades of service, but represent a much higher initial investment.

The Baseline Lifespan: What the Numbers Suggest

In the world of industrial equipment, lifespan is often measured in operating hours rather than years. However, for planning and depreciation purposes, a yearly estimate is useful.

A well-maintained industrial air compressor, operating under normal conditions, should last between 10 and 15 years. High-quality rotary screw models, in particular, can often exceed 100,000 operating hours with proper care, potentially pushing their service life closer to 20 years.

However, this is just a baseline. This number is an ideal, a target that can only be achieved when a multitude of influencing factors align perfectly. The reality for most MRO managers is that this lifespan is constantly being challenged by the operational environment.

Critical Factors Influencing Compressor Longevity

The difference between a compressor that lasts 7 years and one that lasts 17 often comes down to a handful of critical variables. Mastering these factors is the key to maximizing your return on investment and ensuring operational stability.

1. Quality of Manufacturing & Materials

This is the foundation of longevity. A compressor built with precision-machined components, superior-grade cast iron, and high-tolerance bearings will inherently withstand the rigors of industrial use better than a unit built to a lower price point. Sourcing from manufacturers with a proven track record of quality is paramount. This is where the value of American manufacturing becomes tangible. Our commitment at Maden.co is to provide a platform where buyers have transparent access to over 800+ verified U.S. manufacturers, ensuring that the components you source are built with American Manufacturing Pride and a commitment to industrial excellence.

2. Correct Sizing and Installation

One of the most common reasons for premature compressor failure is improper sizing.

- Undersized Compressor: An undersized unit will run constantly, exceeding its designed duty cycle. This leads to overheating, excessive wear on motors and bearings, and a dramatically shortened lifespan.

- Oversized Compressor: A unit that is too large for the application will "short cycle," turning on and off frequently. This causes excessive wear on the starter, motor, and other electrical components, and allows moisture to build up in the system, leading to internal corrosion.

Proper installation is equally critical. The unit must be level, have adequate ventilation to prevent overheating, and be connected to a stable and clean power supply.

3. The Operating Environment

The physical location of the compressor plays a massive role in its health.

- Ambient Temperature: High ambient temperatures force the compressor's cooling system to work harder, accelerating oil degradation and increasing the risk of overheating.

- Air Quality: A dusty, dirty, or chemically-laden environment is the enemy of a compressor. Contaminants can clog air filters, foul coolers, and be ingested into the compressor itself, causing abrasive wear on internal components.

- Humidity: High humidity introduces more moisture into the system, which can overwhelm air dryers and lead to condensation within the tank and air lines, causing rust and corrosion from the inside out.

4. Power Supply Quality

Industrial compressors are powerful machines that are sensitive to electrical fluctuations. Unstable voltage, power sags, or "dirty" power with harmonic distortions can damage the motor windings, contactors, and control systems, leading to premature electrical failure. A dedicated, properly-sized circuit with appropriate surge protection is a must.

5. The Maintenance Protocol (The Game Changer)

More than any other factor, a rigorous and consistent maintenance schedule will determine the ultimate lifespan of your air compressor. Deferring maintenance to save on short-term costs is a guaranteed path to catastrophic failure and far greater long-term expense. A proactive MRO strategy is not a cost center; it is an investment in uptime.

The Proactive MRO Strategy: A Maintenance Deep Dive

A comprehensive maintenance plan can be broken down into daily, weekly, monthly, and annual tasks. Delegating these responsibilities and maintaining a detailed service log is essential for accountability and tracking the health of the asset over time.

Daily Checks

- Visual Inspection: Look for any signs of oil or air leaks.

- Drain Condensate: Manually drain moisture from the receiver tank and any drop legs in the system (unless an automatic drain is installed and functioning correctly).

- Check Oil Level: For lubricated models, ensure the oil level is within the manufacturer's specified range on the sight glass.

- Listen for Unusual Noises: Be attentive to any new sounds like grinding, knocking, or excessive vibration.

Weekly Checks

- Clean Air Intake Filters: In a dusty environment, this may need to be a daily task. A clogged filter restricts airflow, forcing the compressor to work harder and run hotter.

- Wipe Down the Unit: Clean any accumulated dust and oil from the compressor, motor, and coolers. This helps with heat dissipation and makes it easier to spot new leaks.

Monthly Checks

- Inspect Belts: For belt-driven models, check for tension, wear, and cracking.

- Test Safety Relief Valve: Briefly pull the ring on the pressure relief valve to ensure it is not stuck.

- Check All Fittings and Hoses: Ensure all connections are tight and hoses are free from cracks or bulges.

Quarterly and Annual Service

- Change Compressor Oil: Follow the manufacturer's recommendation for oil change intervals, which are typically based on operating hours. Use only the specified type of lubricant.

- Replace Oil Filter and Air/Oil Separator: These are critical components that protect the compressor and the quality of the compressed air.

- Motor Maintenance: Lubricate motor bearings according to the manufacturer's schedule.

- Professional Inspection: Have a qualified technician inspect the entire system, check electrical connections, calibrate controls, and perform vibration analysis to preemptively identify bearing wear.

Recognizing the Signs: Early Warnings of Compressor Failure

A compressor rarely fails without warning. For an MRO buyer or procurement manager, recognizing these signs provides a crucial window to source a replacement before a catastrophic failure disrupts operations.

- Unusual Noises: Grinding or knocking sounds often indicate failing bearings or internal contact within the airend. Squealing can point to worn belts or bearings.

- Reduced Output: If the system struggles to reach its target pressure or the pressure drops quickly during use, it could be a sign of worn piston rings, screw wear, or leaking valves.

- Constant Tripping of Breakers: This often points to an aging motor that is drawing too much current as it struggles to start or run under load.

- Excessive Oil Consumption: If you find yourself constantly topping up the compressor oil, it's likely being pushed past worn seals or rings into the air system (oil carryover).

- Visible Fluid Leaks: Any puddle of oil under the unit is a clear sign that a seal or gasket has failed.

- Increased Vibration: An increase in vibration can signal misaligned belts, failing bearings, or loose anchor bolts.

When these symptoms appear, the clock is ticking. This is the moment when having a reliable sourcing partner becomes a strategic advantage.

Sourcing Your Replacement: The Maden.co Advantage

For a procurement manager under pressure to find a replacement, the challenges are numerous: long lead times from overseas suppliers, questions about quality and compliance, and the capital expenditure of a major equipment purchase. This is precisely where our platform transforms a crisis into a controlled, efficient process. We are dedicated to democratizing access to American manufacturing, proving that U.S.-made components are as accessible and convenient as any global alternative.

Supply Chain Resilience & Transparency

By connecting you directly with our network of over 800+ verified U.S. manufacturers, we help you build a more resilient supply chain. Sourcing domestically drastically reduces lead times, minimizes shipping complexities, and provides a clear line of sight into the manufacturing standards of your components. When you need a reliable, two-stage unit that can handle the demands of a professional repair shop or light industrial work, a product like the FS-Curtis CW Series 7.5 HP Two-Stage Industrial Air Compressor can be sourced with confidence, knowing it's backed by American engineering and support.

Strategic Financial Tools

We understand that a new industrial compressor is a significant investment. To empower businesses and facilitate necessary upgrades, we offer a key differentiator: Instant Financing. This feature, available during checkout, is more than just a payment option—it's a strategic tool. It allows you to manage cash flow effectively, preserve capital for other operational needs, and acquire the right equipment without delay. You can apply for Instant Financing at checkout to streamline your capital-intensive projects and avoid letting budget constraints dictate critical infrastructure decisions.

If you have specific sourcing questions about finding a compressor that meets your exact PSI, CFM, and voltage requirements, our team is ready to help. Please don't hesitate to contact us for assistance.

For U.S. Manufacturers: Join the Revival

Our mission is not only to serve buyers but also to champion the manufacturers who are the backbone of our industrial strength. We are building the definitive platform for American-made industrial products, and we are always looking for partners who share our commitment to quality and innovation. If you are a U.S. manufacturer producing high-quality industrial components and want to reach a dedicated market of professional buyers, we invite you to join our cause. Register as a vendor and join the American manufacturing revival.

Conclusion

The lifespan of an industrial air or AC compressor is not a fixed date on a calendar; it is the direct result of strategic decisions made throughout its operational life. It begins with the decision to source a high-quality, well-engineered machine from a reputable manufacturer. It is extended through meticulous installation and a commitment to a proactive, unwavering maintenance schedule. And when the time for replacement inevitably comes, it is preserved through an efficient, transparent procurement process that minimizes downtime and supports a resilient domestic supply chain.

By understanding the factors that influence longevity and recognizing the early signs of failure, you can transform the management of your compressed air system from a reactive necessity to a strategic advantage. We invite you to explore the extensive catalog on Maden.co, where you will find millions of U.S.-made products designed for industrial excellence. Equip your facility with components you can trust, streamline your procurement with powerful tools like Instant Financing, and become a part of the movement proving that America's manufacturing revival is here.

Frequently Asked Questions (FAQ)

1. What's the typical difference in lifespan between a reciprocating and a rotary screw compressor?

In an industrial setting with high demand, a rotary screw compressor generally has a longer lifespan. They are designed for 100% duty cycles and continuous operation, often lasting 60,000 to 100,000+ hours with proper maintenance. A reciprocating compressor is better suited for intermittent use; subjecting it to a continuous duty cycle will cause it to wear out much faster, often in under 20,000 hours. The key is matching the technology to the application.

2. When a compressor fails in a large HVAC unit, can I replace just the compressor?

In many industrial and commercial HVAC systems, the compressor is a replaceable component, unlike smaller residential units where the entire condensing unit is often replaced. A qualified HVAC technician can recover the refrigerant, remove the failed compressor, and braze a new one into the system. However, it's critical to diagnose why the original failed (e.g., acid burnout, electrical issues) to prevent a repeat failure of the new component.

3. How does improper sizing most directly affect a compressor's lifespan?

Improper sizing creates a destructive cycle. An undersized compressor runs constantly, leading to severe overheating. Heat is the primary enemy, as it breaks down lubricating oil, causing accelerated wear on bearings, pistons, or screws. An oversized compressor short-cycles, causing extreme wear on the motor starter and contactors. This frequent inrush of current can also fatigue motor windings, leading to premature electrical failure.

4. Is a U.S.-made industrial compressor demonstrably better?

While quality can vary globally, sourcing a U.S.-made compressor from a verified manufacturer offers several distinct advantages that contribute to a lower Total Cost of Ownership (TCO). These often include higher-grade materials (like domestic cast iron), stricter quality control tolerances, easier access to OEM replacement parts and technical support, and adherence to familiar industry standards (NPT, ANSI). This translates to enhanced reliability, better serviceability, and a more resilient supply chain, which are critical in professional industrial environments.