Check-All® UV Style Union Insert Check Valve - 1.5in, 1.50psi, 316 Stainless Steel

Check-All® UV Style Union Insert Check Valve - 1.5in, 1.50psi, 316 Stainless Steel

SKU:UVS-b5a1fc

High-quality Check-All® UV Style Union Check Valve - 1.50psi, 316 Stainless Steel, ISO 9001 Certified

Regular price

$129.99

Regular price

Sale price

$129.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

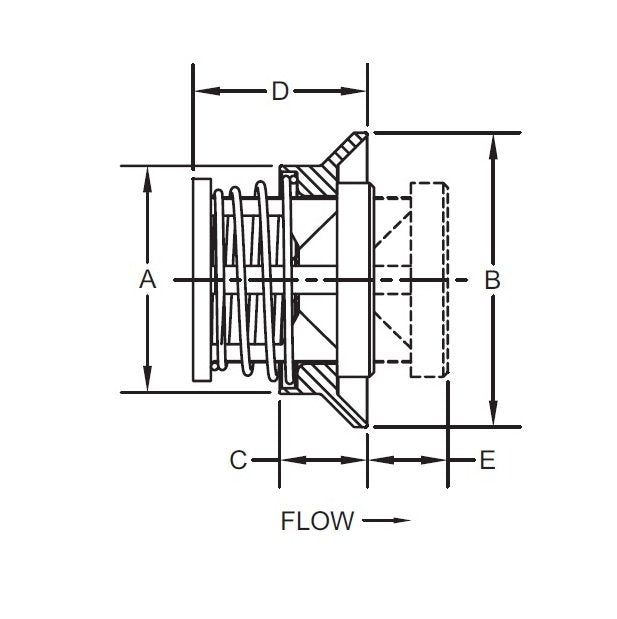

The Check-All® UV Style Union Insert Check Valve offers seamless integration into threaded pipe systems, providing an efficient way to install a check valve. Made of high-quality 316 Stainless Steel, it ensures durability and reliability in various applications. With a standard cracking pressure of 1.50 psi, this valve can be used for pressure relief or vacuum breaking. Compliant with ISO 9001 certifications, this valve guarantees performance and quality in both horizontal and vertical positions, meeting the highest institutional procurement standards.

Product Specifications

Additional Information

The valve works equally well in either a horizontal or vertical position with proper spring selection. Each Union Insert valve is furnished with a metal tag, which is quickly attached to the union when the valve is installed. This provides a permanent visual notification that the union contains a check valve. The UV valve can also be used as a low pressure relief valve or vacuum breaker by using the desired spring settings.PED Compliance Statement: Due to the unique "insert" design of our 3S, SC, CB, TC, SI, & UV, style check valves, they do not constitute an "identifiable pressure bearing housing" as defined in PED Guideline 1/8. These styles must be installed into either ferrules or fittings to create a pressure bearing housing. Instead, they are classified as "components of pressure equipment" as defined in PED Guideline 1/8. As a result, these valves can be sold in the European Community and no CE Mark is required.In addition applications where the maximum allowed operating pressure is 0.5 bar (7.2 psi) or less, do not fall under the PED, regardless of the valve style.

Note

Bore of union must be equal to I.D. of schedule 40 pipe. Use ground joint unions with 45º seat only (union not included).Made in USA.

Specifications Body Material

316 Stainless Steel = SS | Alloy 20 = A2 | Alloy B = HB | Alloy C-276 = HC | Brass = BR | Carbon Steel = CS | Monel® 400 or Alloy R405 = MO | Titanium = TI

Specifications Body Material Availability

316 Stainless Steel (SS) - Standard | Alloy 20 (A2) - Semi-Standard | Alloy B (HB) - Contact the factory for these or other materials | Alloy C-276 (HC) - Semi-Standard | Brass (BR) - Standard | Carbon Steel (CS) - Standard | Monel® 400 or Alloy R405 - Semi-Standard | Titanium (TI) - Contact the factory for these or other materials

Specifications Certifications

European Conformity (CE) Non-PED Statement | International Organization for Standardization (ISO 9001) Certified

Specifications Nominal Pipe Size

1-1/2 in

Specifications Non Shock Pressure Rating At 100 Degree Fahrenhei

3000 psig

Specifications Note For Material

Listed above are the most common material selections. Please contact the factory for additional options.

Specifications Seat Material

"Metal-to-Metal" = MT | Aflas® = AS | Buna-N = BN | Ethylene Propylene Diene Monomer (EPDM) = EP (EP seats not recommended for use with Carbon Steel valves.) | Fluoro-Elastomer (FKM) = VT | Neoprene = NE | Perfluoroelastomer = KZ | Polytetrafluoroethylene (PTFE) = TF

Specifications Size Code

J

Specifications Special Options

RT = Reverse Trim | T = FEP Encapsulated Spring

Specifications Spring Material

17-7PH Stainless Steel = PH | 316 Stainless Steel = SS | Alloy C-276 = HC | Inconel® X750 or Alloy X750 = IX | Monel® 400 = MO | Titanium = TI

Specifications Standard Cracking Pressure

1.50 psi

Specifications Valve Style

UV