COULOSCOPE® CMS2 Electrochemical Thickness Measuring Instruments

COULOSCOPE® CMS2 Electrochemical Thickness Measuring Instruments

SKU:COU-1e48c4

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Measurement of coating thicknesses and electrochemical potentials according to the coulometric methodThe CMS2 measures the thickness of virtually any metallic coating, including multilayer, on any substrate material; it works according to the coulometric method by anodic dissolution (DIN EN ISO 2177). The simple handling and menu-supported operator guidance makes the CMS2 the ideal solution for both production monitoring in the electroplating industry and incoming inspection on finished parts. The device comes equipped with nearly 100 predefined measuring applications for different coating systems (e.g. zinc on iron, nickel on brass), as well as various de-plating speeds (e.g. 1, 2, 5, and 10 μm/min). These can also be combined for measuring multilayer systems.

Product Specifications

Additional Information

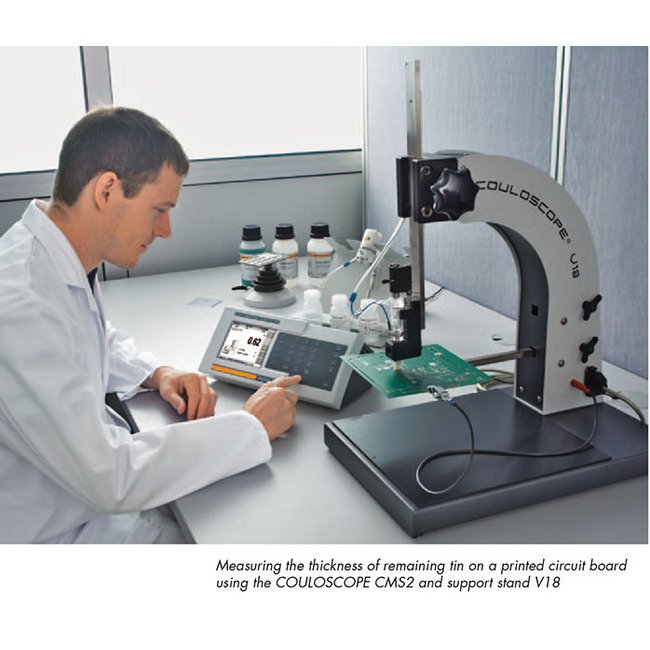

Coulometry is an electrochemical analysis method that is simple and easy to execute and can be applied in order to determine the thickness of metal coatings. While primarily used for checking the quality of electroplated coatings, this method is also suitable for monitoring the thickness of the remaining pure tin on printed circuit boards.One of the simplest methods for measuring coating thickness, the coulometric method can be employed for a wide variety of coating-substrate combinations. Especially with multilayer coatings, it offers a cost-effective alternative to the X-ray fluorescence method whenever a destructive measurement method can be tolerated.

Applications

The robust and user-friendly COULOSCOPE® CMS2 is suitable for both production monitoring in the electroplating industry and incoming inspection on finished parts.Many common single and duplex coatings, such as Zn on iron or Sn/Ni on copper, can be measured quickly and simply using the CMS2. The method provides for accurate measurements of practically any metal coating. In the thickness range of 0.05 - 50 μm, no pre-settings are required for many materials; substrate composition and geometry are also irrelevant to the measuring process.One of the most frequent applications is the measurement of the remaining pure tin on printed circuit boards in order to ensure solderability. Multilayer coatings such as Cr/Ni/Cu on iron or plastic (ABS) substrates, often found in high-quality bathroom fittings for example, can also be measured with this method.

Calibration

The calibration process establishes a correction factor that takes such variables into account as departures in the actual diameter of plastic seals from the reference value, deviations in alloy composition and fluctuations in the density of the coating material.

Features

Large, high-resolution color displaySimple instrument operation and graphically supported user guidancePartially-automated measurement with support stand V18Simple selection of de-plating speed (0.1 - 50 μm/min) and de-plating area (0.6 - 3.2 mm Ø)Graphic display of the voltage profile in the measuring cellGraphic and statistical analysis optionsVarious languages and measurement units to choose from

Optional Accessories

The extensive assortment of available accessories facilitates effective work practices, ensures safe storage and provides aids for fastening specimens.

Specifications De Plating Area Diameter

0.6 to 3.2 mm

Specifications De Plating Speed

0.1 to 50 µm/min

Specifications Industry Standardscertifications

European Standards International Organization for Standardization (DIN EN ISO 2177)

Specifications Intended Application

Coating Thickness | Material Testing

System Overview

A functional measuring station comprises a COULOSCOPE® CMS2 and support stand with a measuring cell (e.g. STEP measuring cell). Various stand designs, including measuring cells, are available to suit a range of applications.

Test Method

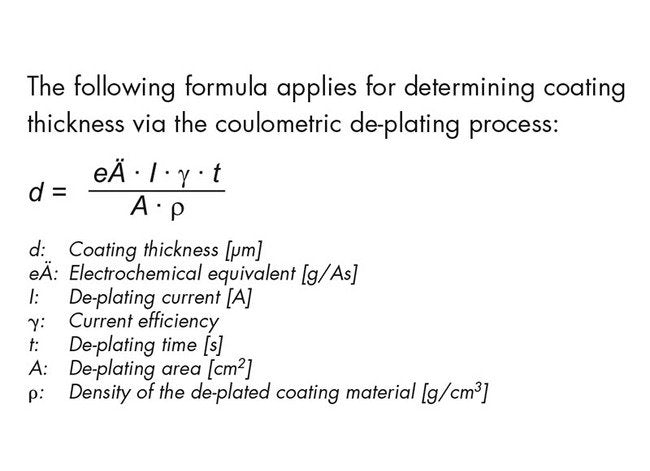

Coulometric coating thickness measurement according to DIN EN ISO 2177The COULOSCOPE® instrument series operates according to the coulometric test method as per DIN EN ISO 2177. This involves dissolving a metal coating off of its metallic or non-metallic substrate by means of an electrolyte under controlled electric current, i.e. reversing the electroplating process (de-plating). The current required for de-plating is directly proportional to the mass of the metal to be removed. A clear correlation between the de-plating time and the coating thickness arises when the test current and area are both kept constant.De-plating takes place in a measuring cell - a kind of miniature electrolytic bath. The measuring area is defined by a plastic gasket attached to the measuring cell. The electrolytes used are formulated for the various coating materials such that de-plating does not start until current flows. The de-plating process is initiated by the instrument’s electronics. A pump circulates the liquid within the measuring cell, continually refreshing the electrolyte in contact with the de-plating area, thereby ensuring uniform de-plating. Depending on the size of the area to be measured, gaskets with various diameters are available for the measuring cell.