COULOSCOPE® CMS2 STEP Electrochemical Thickness Measuring Instruments

COULOSCOPE® CMS2 STEP Electrochemical Thickness Measuring Instruments

SKU:COU-7f975a

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

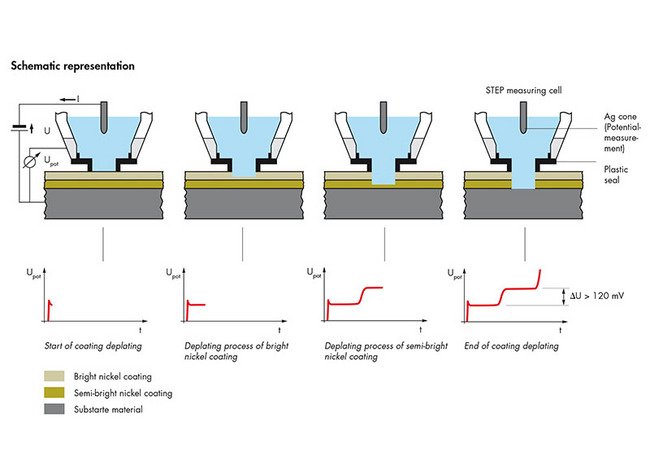

Measurement of coating thicknesses and electrochemical potentials according to the coulometric methodThe CMS2 STEP features the additional STEP Test (Simultaneous Thickness and Electrochemical Potential determination) function. It is used for standardized STEP Test measurements of individual coating thicknesses and differences in potential (according to ASTM B764-94 and DIN 50022) in the quality control of multiplex nickel coating systems. The coating thickness measurement is carried out according to the coulometric method, while the potential profile is captured using a silver reference electrode coated with AgCl.

Product Specifications

Additional Information

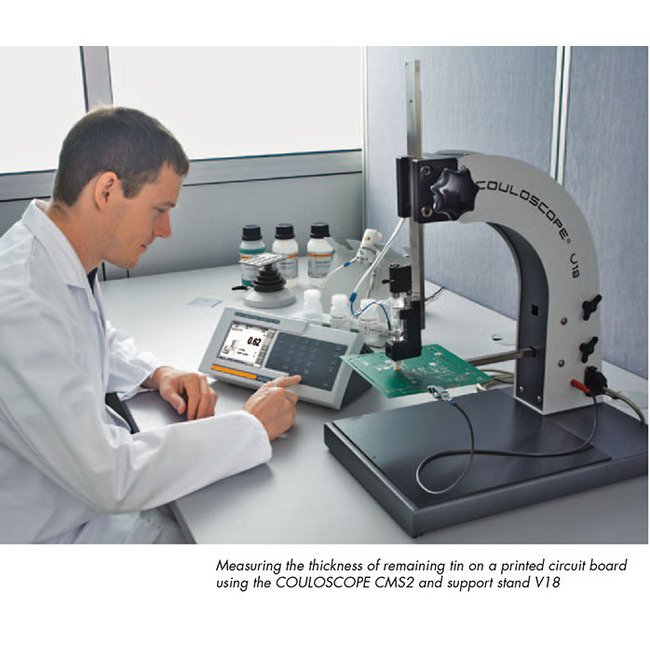

Coulometry is an electrochemical analysis method that is simple and easy to execute and can be applied in order to determine the thickness of metal coatings. While primarily used for checking the quality of electroplated coatings, this method is also suitable for monitoring the thickness of the remaining pure tin on printed circuit boards.The STEP Test is used to measure simultaneously the differences in potential and the thicknesses of multiplex nickel coatings, allowing for assessment of their corrosion behavior. This method has established itself as a standard for this special area of application.

Applications

Quality control of multiplex nickel coatings calls for instruments that can check both the thickness and the electrochemical potential immediately after the coating procedure. Developed specifically for this purpose, the COULOSCOPE® CMS2 STEP measurement system is suited to the harsh environment typical of electroplating plants; it is simple to operate, and handling the reference electrode is straightforward. Electrolytic nickel-plating is commonly used for decorative corrosion protection and for improving such mechanical surface properties as hardness.Especially in the automotive industry, nickel-plated components must meet stringent specifications with regard to corrosion behavior; single-layer nickel coatings are not suitable for this purpose. As a result, complex coating systems consisting of two, three or even four different nickel layers, including additional coatings of chromium or copper, are being developed.

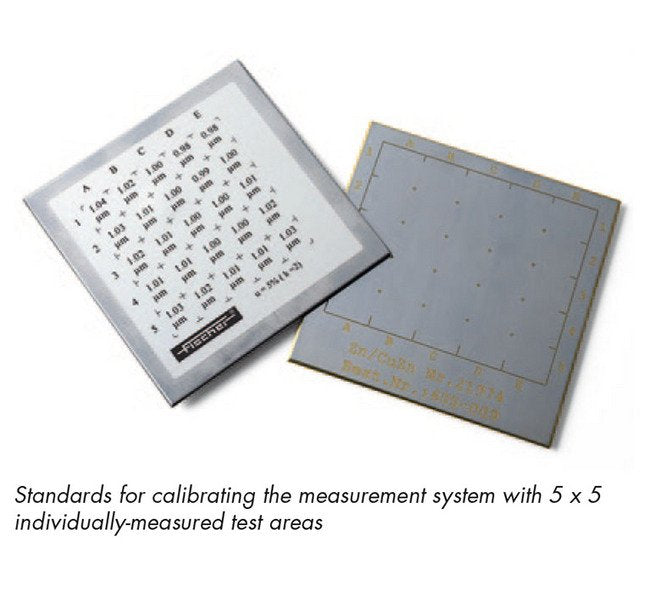

Calibration

The calibration process establishes a correction factor that takes such variables into account as departures in the actual diameter of plastic seals from the reference value, deviations in alloy composition and fluctuations in the density of the coating material.

Features

Simultaneous measurement of coating thickness and differences in potentialSimple conditioning of the silver reference electrodeAdjustable de-plating current

Optional Accessories

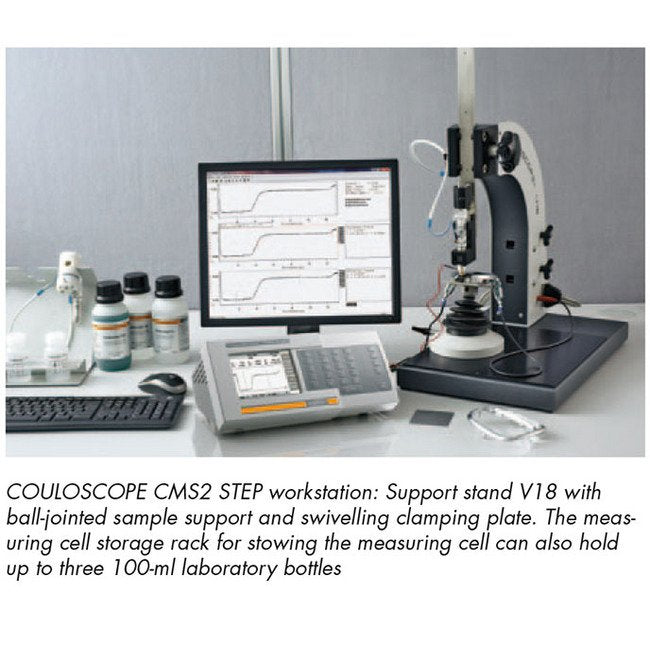

The extensive assortment of available accessories facilitates effective work practices, ensures safe storage and provides aids for fastening specimens.

Specifications Industry Standardscertifications

American Society for Testing and Materials (ASTM B764-94) | European Norms (DIN EN) 50022

Specifications Intended Application

Coating Thickness | Material Testing

System Overview

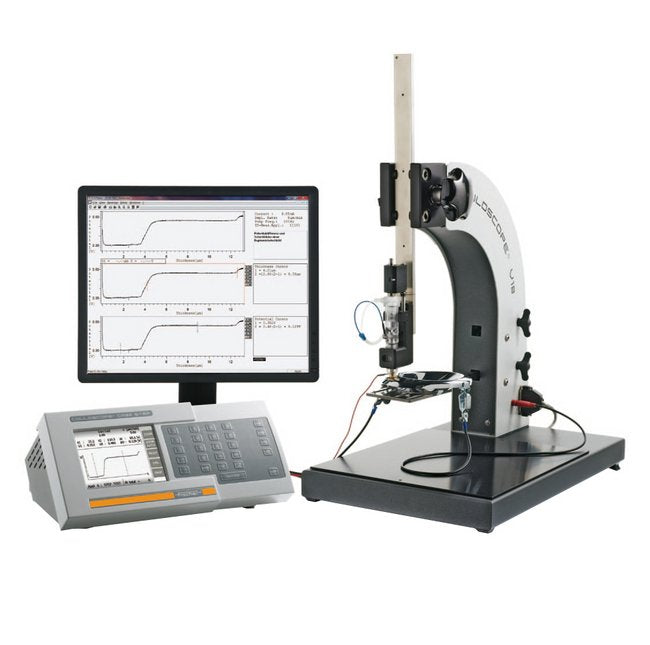

A functional measuring station comprises a COULOSCOPE® CMS2 STEP and support stand with a measuring cell (e.g. STEP measuring cell). Various stand designs, including measuring cells, are available to suit a range of applications.

Test Method

STEP Test measurement according to ASTM B764 - 94 and DIN EN ISO 2177The STEP Test (Simultaneous Thickness and Electrochemical Potential determination) is a long-standardized method for simultaneously determining individual coating thicknesses and the differences in electrochemical potential between the individual layers of a multiplex nickel coating system. The coating thickness measurement is carried out according to the coulometric method, while the potential profile is captured using a silver reference electrode coated with AgCl. The potential profile is shown on the display; individual coating thicknesses and differences in potential can be viewed by positioning the cursor correspondingly on the plot.To obtain comparable results with this method, the reference electrode must always be kept the same distance from the specimen; therefore, a special measuring cell is utilized. The silver reference electrode is a cone-shaped ring that forms the lower housing component of the measuring cell, further requiring only the obligatory gasket. This measuring cell design ensures a consistently uniform distance between the reference electrode and the specimen.