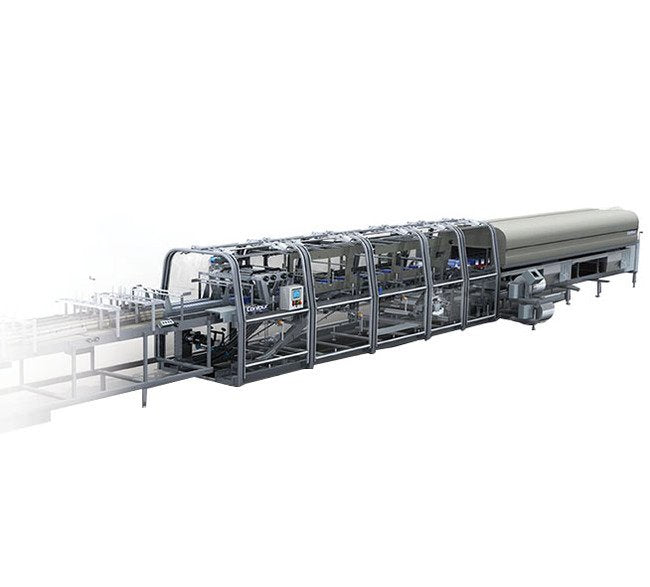

Douglas Contour® 105 Shrink Wrapping System

Douglas Contour® 105 Shrink Wrapping System

SKU:MAC-4e8979

Enhance packaging efficiency with the Douglas Contour® 105 Shrink Wrapping System. Advanced heat tunnel technology, servo motors, and up to 105 cycles/min speed ensure premium package appearance and durability.

Regular price

$34,999.99

Regular price

Sale price

$34,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Upgrade your packaging efficiency with the Douglas Contour® 105 Shrink Wrapping System. Featuring advanced heat tunnel technology, servo motors, and a speed of up to 105 cycles/min, this system ensures consistent package appearance and durability. With innovative features like the Revolutionary Heat Tunnel and Balanced Laminar Airflow, it optimizes shrink wrap performance while maintaining high reliability and efficiency. Suitable for a range of industries, this system offers precision, flexibility, and seamless operation to meet accelerated production challenges.

Product Specifications

Features Features

Higher Productivity Through the Power of InnovationAvailable as stand-alone or fully integrated systems for film-only, pad, u-board and tray applications, Douglas gives you more with Contour® shrink wrap systems. More operational advantages, more consumer appeal, more of everything you need to stay ahead of the pack. The Contour® Series offers a full spectrum of innovative features that maximize speed and easily accommodate large size ranges and pack-patterns for the food and beverage industries.Revolutionary Heat Tunnel Protects and Enhances Your BrandThe Douglas Contour® heat tunnel is designed with the aesthetics of your product in mind. Whether your application calls for single or multiple lane production, unprecedented heat and airflow management ensures minimal graphic distortion, consistent bull's-eyes and a tighter, more durable wrap. Enhanced tunnel operations significantly reduce noise and exterior heat temperatures, contributing to a quieter, cooler plant environment.High Efficiency Heat SourceThe heat system is designed so that the air supplied to the distribution system is perfectly uniform, eliminating film distortion due to hot or cold pockets. The Contour® continuously recycles the air as it cools, decreasing the amount of energy required to reach operating temperature. A well insulated heat tunnel minimizes heat loss, which also maintains a safe outer surface temperature.Balanced Laminar AirflowAt the heart of this innovation is a combination of design features, which result in "laminar" airflow, rather than "turbulent" airflow, which most shrink systems use today. Unlike turbulent airflow, which causes a multitude of shrinking inconsistencies, our proprietary laminar design precisely balances the heated air, perfectly "coating" the film from every direction, shrinking and sealing the film in an even, predictable manner.Precision Lap Seam WeldingEvenly heated air passing through the conveyor web contacts the film under the product resulting in consistent "air weld" of the film lap seam. Tunnel chain temperature and airflow are precisely adjusted through product specific recipe-driven changeovers, optimizing performance. Poor lap sealing due to insufficient heat or holes melted in the seams due to overheating are eliminated, resulting in strong and even seams that hold up to the rigors of distribution and stocking operations.Flexible, Low Pressure Conveying and Product HandlingAll Douglas infeed conveying solutions are engineered to ensure gentle product handling and to maintain the highest package integrity. These versatile systems handle multiple product sizes and package configurations on demand, at high speeds.Smartrak® II - Mass flow infeed design eliminates soft bottle bridging and removes gaps to ensure pack-pattern accuracy and continuous product flow. Distinguishing features include modulated speed control programming for surge pressure relief at the choke point, single solid adjustment cross-members, tool less clamps and pinned lane guide adjustment positions for stable operation and quick, accurate changeovers. By eliminating many mechanical changeover adjustments and replacing them with a one clamp design, changeovers are seamless and fast.Efficient Pack-Pattern Collating and LoadingDouglas Machine redefines the role of pack pattern collating in high efficiency lines. Dramatic improvements to line throughput and product volume are realized, while providing maximum product handling stability with patented, proven technology.Slipstream⢠HS/Slipstream⢠SS - pinless metering using slip sheet methodology and servo technology to gently meter bottled, cartoned, canned and other products in appropriate pack-patterns without the use of tampers or escapement pins. Remarkable stability control allows for faster handling than traditional metering methods. Tool free changeovers and the intuitive HMI control panel also increase productivity.The appropriate technology is determined based on speeds and your product. Slipstream⢠SS offers more stability as product moves faster, especially with unstable product or odd size/shaped packaging.Maximizing Speed and EfficiencyFrom infeed, through product handling to our industry-leading shrink process, Contour® offers innovative, common sense solutions that optimize performance throughout the process. Not satisfied with simply modifying existing technology, Douglas continually challenges conventional thinking to develop real-world advantages that deliver optimum throughput and unparalleled adaptability.

Note Note

Specifications subject to change without notice.

Power Alternating Current Ac Voltage

480 V

Power Frequency

50 Hz | 60 Hz

Power Note For Power

Other Power Sources Available.

Power Number Of Phase

3

Power Voltage Drop

One Glue Drop | One Main Drop

Product Size Range Across Machine

8-1/2 to 22 in | 215 to 560 mm

Product Size Range Direction Of Travel

5 to 15-3/4 in | 130 to 400 mm

Product Size Range Vertical

3-1/2 to 12 in | 90 to 305 mm

Specifications Adjustments

Threaded screws, handwheels and handknobs with position pointers and scales. Digital scales, phase adjustments and optional auto-adjust packages

Specifications Air Pressure

Per Project Specification

Specifications Brand

Contour® | Douglas

Specifications Drive

Servo Motors

Specifications Electrical

Allen Bradley ControlLogix motion and logic control or per project specificationNEMA 12 wiring and enclosuresNEMA 4 or 4X wiring and enclosures (optional)

Specifications Finish

Gray metallic baked-on epoxy powder coat.Other colors per project specification. All parts in contact with product are stainless steel, anodized aluminum, and plastic. OEM parts are manufacturers' standard finish

Specifications Flight Chains

Application Dependent

Specifications Guarding

Polycarbonate GuardingOther guard packages per project specification (optional)

Specifications Legs

Threaded

Specifications Maximum Film Length

42 in | 1070 mm

Specifications Minimum Film Length

18 in | 460 mm

Specifications Note For Standard Film Width

Model Dependent

Specifications Pitch

Application Dependent

Specifications Printednon Printed Film Thickness

1 to 3 mil

Specifications Speed

Up to 105 cycles/min

Specifications Standard Film Width

30 in | 760 mm

Specifications Type

Shrink