FISCHERSCOPE® MMS® PC2 Thickness Measuring Equipment

FISCHERSCOPE® MMS® PC2 Thickness Measuring Equipment

SKU:FIS-d6bafd

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Universal Multi-Measuring System for Coating Thickness Measurement and Material TestingThe FISCHERSCOPE® MMS® PC2® is used wherever quality is a top priority: in incoming inspection, in final inspection, during ongoing production, for sampling or routine tests. And that in all industries. As a result of its modern design, the MMS® PC2® can be adapted specifically to your needs and expanded at any time. Whether coating thickness, electrical conductivity or ferrite content, with the MMS® PC2® you will always measure precisely and correctly.MMS® PC2® - one measuring instrument for all measuring applications.

Product Specifications

Adaptable Due To Modular Structure

100 different applications - eight slots and more than 60 probesDue to its modular design, the MMS® PC2® is always right for your applications. Based on your measuring application, we assemble the measuring instrument for you with the right module boards and probes.Eight different module boardsThe measurement of the physical quantities of coating thickness, electrical conductivity and ferrite content requires different test methods. In the case of coating thickness measurement, different test methods are used, depending on the coating/substrate material combination. In order to cover this wide range, we have developed eight different module boards for the MMS® PC2®.Changed requirementsYou can upgrade the MMS® PC2® at any time with further module boards and probes.InterfacesLAN network connection5 USB connections for PC, printer etc.RS232 interface for connecting support stand, XY measuring stage, digital measuring aids or radio interfaceMulti-function connector, e.g. for connecting signal lights for reporting when tolerance limits are exceededOptional: connection for PLC integration

Applications

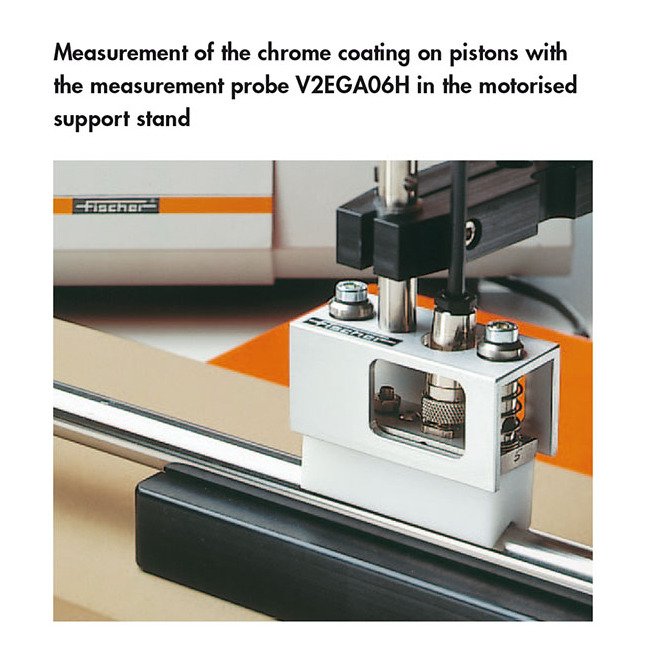

Measurement of thin organic coatings, e.g. oils, with the hand probe Z15NG-TCHand probe with beta emitter for measurements according to the radiometric beta-backscatter method, an integrated temperature sensor serves to automatically compensate for the beta radiation damping through the air at different temperatures.Precise measurements on small parts with the motorized support stand V12 MOTThe Fischerscope® MMS® PC2® automatically controls the upwards and downwards motion of the support stand and the measurement.Measurement of the chrome coating on pistons with the measurement probe V2EGA06H in the motorized support stand.Incoming inspectionMeasuring station with several module boards and probes for incoming inspection, mounted on a transport trolley for measuring different parts.

At Home In All Industries

AutomotiveElectronics industryPaint industryCoating technologiesGold, watches, jewelryMaterial analysis and material testing

Coating Thickness Measurement

Measurement of the coating thickness with the following material combinations:Almost all coating materials on metalsDuplex coating systemsMetallic coatings on electrically non-conductive materialsOrganic coatings, e.g. oil or grease films

Data Evaluation Data Export

You can export your measuring data quickly and easily. It is possible to define what to export in templates. You can create a different template for each application.Possible formatsPDF, ASCII, Excel, Q-DAS, HTMLOnline or offline output of the measurements via the USB interface to a PCOnline or offline output of the measurements via the RS232 interface to a PCExport of result print forms as text files, ASCII files for importing to Excel spreadsheets, in Q-DAS or HTML format

Data Evaluation Evaluation And Statistics Functions

The Fischerscope® MMS® PC2® offers a wide variety of possibilities for evaluating your measuring results.Display of important statistical characteristics such as mean value, standard deviation, min, max, and rangeStatistics display of the important characteristics in the block and final resultGraphic display as a histogram, sum frequency chart, FDDPossibility of entering the process tolerance limits and calculation of the corresponding process capability indices cp and cpk

Data Evaluation Fischer Datacenter

The PC software Fischer DataCenter is included in the scope of supply of the Fischerscope® MMS® PC2®. The DataCenter software makes it possible to easily and conveniently generate individual reports and design them with your own logos, images and graphics. You can integrate any desired measurements, statistical values and graphic displays via drag and drop. In addition, you can create report templates on the basis of scanned forms.

Data Evaluation Measurement Print Forms

For a clear presentation of your measurement results, you can create print forms that present the measurements and statistical evaluations in a clearly organized manner. It is possible to incorporate e.g. your company logo and a sketch of the specimen in the print forms. You may define the layout and contents of a print form in templates. You can create a separate template for each application.

Data Evaluation Simple Visualization Of The Process Quality With

The Fischerscope® MMS® PC2® offers the patented factory diagnosis diagram (FDD®) from Fischer, a graphic evaluation possibility that visualizes the process at a glance. An easy-to-interpret chart provides a graphic overview of the distribution of manufacturing parameters such as e.g. the coating thickness. As a result of the color display, you receive information for optimizing the production process quickly and easily without statistical calculations of your own.

Evaluation And Data Export

Statistics functions for evaluation of the measurements: sum frequency chart, histogram and factory diagnosis diagram (FDD®)Various graphic measurement displays for a quick overview of the production process and the product qualityCustomer-specific recording of the measurement dataExport of the result print forms and the measurements in different data formats for evaluation in external statistics programsDelivery with PC software FISCHER DataCenter with following functions: transfer and archiving of measurements, comprehensive statistical and graphic evaluation possibilities, easy creation and printing of individual test reports

Features

Coating thickness measurement and material testing with only one instrumentSturdy and very versatile bench-top instrument as a multifunctional measurement system with data archiving and measurement processingUser-friendly work with a large, high-resolution LCD touchscreen and Windows® CEUser interface can be switched between many European and Asian languages

Material Testing

Measurement of the electrical conductivity of nonferrous metalsTesting of the quality of weld seams, ferrite content in austenitic or duplex steels

Measurement By Hand Or Automated

Automatically after touchdown of the probeAt the push of a button or via external startIn predefined time intervalsSemi-automatically with motorized support stand or programmable XY measuring stageAutomated via PLC unitAutomated in production plants

Modular Design

Eight modules with different test methods for coating thickness, conductivity and ferrite content are available

Technical Data Ambient Temperature

+10 to +40 ºC

Technical Data Connectable Printers

Printer with USB connection (2.0 compatible) which features one of the following printer language emulations: PCL, ESC/P

Technical Data Current Rating

1.2 A

Technical Data Data Storage

In the internal memory of the instrument with 256 MB storage spaceOn an external USB stickIn the network

Technical Data Depth

270 mm

Technical Data Documentation

Printout of individual measurements, block and final results, specification limits using print form templates. Printout of SPC charts, histogram, sum frequency chart and FDD®Print form design with customer-specific information. The instrument can store any desired number of print forms

Technical Data Evaluation

Statistical evaluation of test series with mean value, standard deviation, coefficient of variation, maximum and minimum value, number of measurements, individual and block statistics, calculation of the process capability factors.Cp and Cpk; histogram, sum frequency chart with parameters of the distribution shape, FDD®, evaluation from groups of blocks, filtered according to block designations.

Technical Data Fully Equipped Approximate Weight

5 kg

Technical Data Hardware Concept

Housing with 8 slots for module boards with different test methods.

Technical Data Height

170 mm

Technical Data Intended Application

Coating Thickness | Material Testing

Technical Data Measured Quantities

Coating thickness, electrical conductivity, ferrite content, temperature

Technical Data Measurement Accept

Automatic after probe touchdownThrough external startIn continuous running mode at the push of a buttonClocked in selected time intervals either after probe touchdown or after external start

Technical Data Measurement Presentation

Numeric display: list of the measurements with a large numeric display of the last individual measurementSpecification limit display: graphical presentation of the measurements within specified limit valuesSPC chart: control chart presentation as x/R or x/s chartSimple display: numeric display of the last measurementSelectable unit of measurement for measured quantityCoating thickness: metric or imperialFerrite: Fe% or WRC-FNEl. conductivity: % IACS or MS/mTemperature: ºC or ºFFree definition of a further unit of measurement, e.g. g/m2Selectable resolution of the measurement display

Technical Data Measurement Probes

Connection sockets on the module boards for all Fischer probes, simultaneous connection of max. 8 measurement probes

Technical Data Measurement Storage

The instrument stores measurements in application files. The following is also saved in these files: All settings, information on the measurement blocks, date, time and calibration data.Default mode: measurements are saved in successive blocks in the application. Automatic block formation after a specified number n of individual measurements. Automatic calculation of the mean valueMatrix mode: measurements are stored in blocks which are set up in matrix form in the application. Block change in any desired block manually or automatically in a specified order

Technical Data Multi Channel Measurement

Measurements from up to 8 measurement probes are displayed and stored parallel in one application.

Technical Data Power Supply

12 V

Technical Data Screen

Large, high-resolution color display with touchscreen function.

Technical Data Screen Height

130 mm

Technical Data Screen Resolution

800 x 600 px

Technical Data Screen Width

170 mm

Technical Data Software

Windows® CE based program softwareSoftware available in European and Asian languages: German, English, French, Italian, Spanish, Czech, Polish, Turkish, Chinese and JapaneseInputs via touchscreen, mouse or keyboard (USB)Storage of applications, blocking of access to program functions to prevent operating errors, limit value monitoring, outlier control, calibration, block formation

Technical Data Standard Connections

1 x COM1 - RS232 interface1 x LAN network connection4 x USB connections for keyboard, mouse, printer1 x USB connection for PCMulti-function connector with signal outputs for upper and lower limit violations, external startJack socket for connecting e.g. a button for externally triggering the measurement captureVoltage supply via AC adapter 12 V/1.2 A

Technical Data Test Method

Magnetic method (DIN EN ISO 2178)Magnetic induction method (DIN EN ISO 2178, ASTM D7091)Amplitude sensitive eddy current test method (DIN EN ISO 2360, ASTM D7091)Phase sensitive eddy current test method (DIN EN ISO 21968)Micro-resistance method (DIN EN 14571)Beta-backscatter method (DIN EN ISO 3543, ASTM B567a)

Technical Data Width

360 mm