Gardner Denver R Series CAERSB Air Compressor

Gardner Denver R Series CAERSB Air Compressor

Get high-performance reliability with Gardner Denver R Series Air Compressor. Features a 10 hp diesel engine and ASME approval for lasting durability.

Regular price

$5,499.99

Regular price

Sale price

$5,499.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

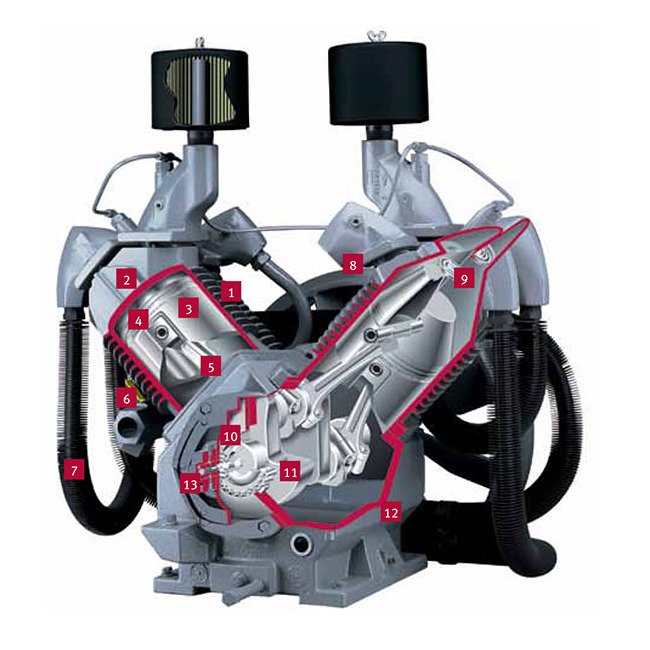

The Gardner Denver R Series CAERSB Air Compressor combines rugged features with high performance, ensuring long-lasting durability and exceptional value. With a 10 hp diesel engine-driven power source and ASME approval, this compressor stands out for its reliability and user-friendly design. Ideal for industrial applications, it features a bare pump, multi-finned cylinders for cooler operation, and balanced pistons for optimal performance.

Product Specifications

Additional Information

Because compressed air is an essential utility, dependability is an essential compressor quality. If your compressor goes down, it can hurt your reputation-and your bottom line. Gardner Denver™ reciprocating compressors are proven units, known for their reliability over decades of use. In addition to dependability, you want a compressor that is user-friendly. Gardner Denver™ comes through again, with a wide selection of configurations and options designed for trouble-free operation.You can’t beat a Gardner Denver™ compressor!

Bare Compressor Pumps

Gardner Denver™ pumps provide dependable service for industrial applications, OEM applications, and pump replacement. The rugged pump design assures reliability and long maintenance intervals.

Base Mounted Air Compressors

Designed for installations where air tanks are remotely located.

Duplex Air Compressors

For extra air delivery when you need it without wasted space. Plus the flexibility of single operation, alternating between compressors, or duplex operation to meet high air demand.

Features Balanced Crankshaft

Constructed of rugged ductile iron with large diameter throws for minimum bearing loads and counterweights to minimize vibration.

Features Balanced Pistons

Aluminum alloy first-stage piston is weight matched to the cast iron second-stage piston, ensuring proper balance.

Features Integral Cylinderhead

Gasketless design eliminates the possibility of blown head gaskets for leak-free operation.

Features Intercoolers

Large-diameter finned tubing is positioned to obtain the greatest cooling effect between stages for maximum compressor efficiency.

Features Large Capacity Crankcase

Rugged cast iron oil reservoir has convenient sight gauge glass, corner oil fill boss and large oil drain.

Features Lightweight Connection Rods

High-density, die-cast aluminum alloy rods minimize reciprocating weight. An integral, precision-bored crankpin bearing and a needle bearing for the piston pin properly distribute bearing loads for longer bearing life than bushings.

Features Loadless Starting

Positive acting, governor-type centrifugal unloader assures longer motor life by allowing the compressor to start unloaded every time.

Features Multi Finned Cylinders

Cooler operating temperatures result in longer life and consistent performance over time.

Features Optimized Cooling Fanflywheel

Precision balanced flywheel has fan blades for optimum compressor cooling and life.

Features Oversized Main Bearings

Tapered roller-type main bearings provide full contact and support of the crank plus delivers the longest possible life.

Features Piston Rings

Three compression rings and one oil control ring provide excellent oil control, minimum blow-by and high efficiency air delivery.

Features Pressure Relief Valves

Located in interstage and discharge.

Features Reliable High Flow Valves

Single-unit, disc-type valves provide low lift and long life. Discs are made of corrosion resistant swedish steel. Valves are easily serviced by removing the manifolds only.

Gasoline Or Diesel Engine Powered Air Compressors

Truck and utility bed mounting design makes these compressors ideal for fleet and field service. Ideal for applications where electricity is not available.

High Performance

R & PL Series compressors are loaded with features designed for day-in, day-out performance. For example, Gardner Denver™’s unique automotive-type domed piston design allows the use of large diameter, low lift valves, while minimizing clearance volume for maximum air delivery.

Long Life

Features such as slow speed operation, rugged cast iron crankcase construction, corrosion resistant steel valves and tapered roller-type main bearings, all contribute to long life.

Note

K - Kohler. Y - Yanmar.Only pressure lubricated units are capable of 250 psig operation. Units tested in accordance with CAGI/PNEUROP Acceptance Test Code PN2CPTC3.All units are built to ISO 9001 standards.

Other Options

Power Monitor that shuts down unit in the event of single phasing, low voltage or phase reversalConstant Speed Control which prevents excessive motor start/stop cycles while saving energyDual Control will allow the compressor to run either in start/stop or constant speed modeNEMA 4 rated parts availableAlternate voltages and TEFC, ODPHE, TEFCHE Electric Motors

Proven Dependability

You rely on compressed air to perform many tasks efficiently. Gardner Denver™ knows that reliability is one of the main reasons for a purchase. Our slow speed, built-in efficiency through design, and the longest compressor warranty in the industry make Gardner Denver™ compressors the proven choice!

Proven Design

Today’s Gardner Denver™ Reciprocating Compressors are the product of decades of design and development. In fact, we introduced the first single-stage compressor in 1919 and have continuously improved its design through innovations in material, production techniques and quality control.

Receivers

Receivers are ASME approved and include a pressure gauge, pressure relief valve, drain valve and service valve.

Select The Configuration That Matches Your Application

With many models from which to choose in both single-stage and two-stage compressors, we can match your exact needs. These configurations, combined with a wide choice of options, provide all the components for a customized installation. They are available in both R-Series splash-lubricated and PL Series pressure-lubricated models.

Select The Options That Match Your Needs

Many options are available to help you develop a Gardner Denver™ compressor package that exactly matches your specific operating requirements.Magnetic StarterFor thermal overload protection, a starter is required for units 3 horsepower and above. Starters available as mounted or unmounted. (Included as standard on most models.)Air-Cooled or Water-Cooled AftercoolerThe factory mounted, heavy-duty, air-cooled aftercooler effectively reduces up to 65% of the moisture from discharged compressed air.Automatic Tank Drain (Pneumatic)Automatically removes water from air receiver upon demand. Eliminates the need for manual purging.Vibration IsolatorsIsolates the compressor unit from the foundation or floor. Reduces noise and protects the unit from any out-of-level floor situation that could cause vibration and damage.Low Oil Level MonitorLow Oil Level Monitor shuts down the unit when oil levels are below an adequate level. Prevents the unit from restarting if oil levels are not at an adequate level.Refrigerated DryerCools compressed air to a 33 ºF - 39 ºF dew point, eliminating additional downstream condensation in the air line. Normally, a dryer should be used in conjunction with an aftercooler.DPR Control PanelThe Microprocessed Duplex Relay Panel was created for controlling a duplex air compressor package. The controller includes visual maintenance and shut down alarms.Gardner Denver™ Compressor LubricantsAEON™ lubricants are blended specifically for Gardner Denver™ compressors for use in harsh compressor environments. They are sourced from extremely stable base stocks and enhanced with carefully selected additive packages to provide long life and superior protection. AEON™ lubricants are suitable for a variety of applications and are available as a mineral oil, synthetic or food-grade synthetic. Available in 55-gallon drums, five-gallon pails, one-gallon bottles and one-quart bottles.

Specifications Airflow Delivery At 175 Psi Pressure Rating

21.7 ft³/min

Specifications Airflow Delivery At 250 Psi Pressure Rating

18.7 ft³/min

Specifications Airflow Displacement At 175 Psi Pressure Rating

27.4 ft³/min

Specifications Airflow Displacement At 250 Psi Pressure Rating

23.6 ft³/min

Specifications Approximate Shipping Weight

518 lb

Specifications Compressor Features

Bare Pump

Specifications Height

29.3 in

Specifications Industry Standardscertifications

ASME Approved | Compressed Air and Gas Institute (CAGI) | Compressed Air Challenge™ | Energy Star Partner | ISO 9001:2008 | NEMA 4

Specifications Length

41.2 in

Specifications Motor Power

10 hp

Specifications Power Source

Diesel Engine Driven

Specifications Width

20.6 in