PHASCOPE® PMP10 Thickness Gages

PHASCOPE® PMP10 Thickness Gages

SKU:PHA-7a43b9

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

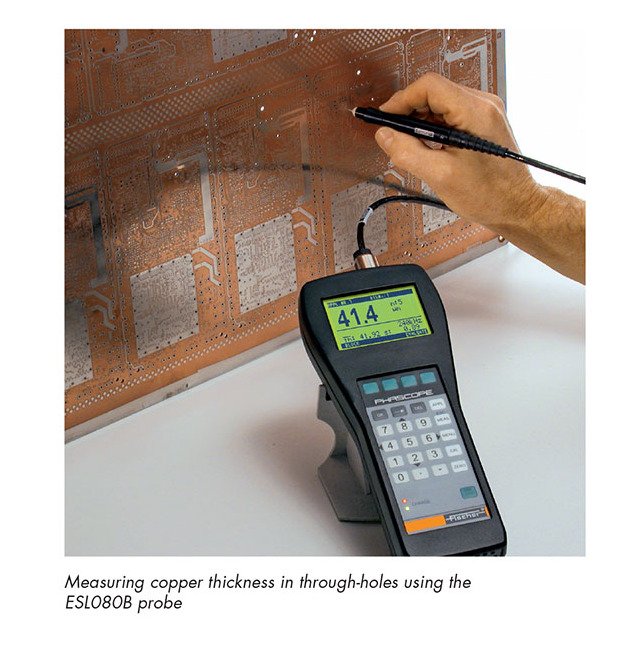

Hand-held instrument for measuring coating thickness on PC Boards and electroplated surfacesPHASCOPE® PMP10 coating thickness measuring instrument for general useThe hand-held PHASCOPE® PMP10 is ideally suited for quality control in the electroplating and printed circuit board (PCB) industries. Because the instrument employs the phase-sensitive eddy current method (ISO 21 968), it allows the measurement of metal coatings on any substrate. A specially designed probe even enables measurements in PCB through holes.

Product Specifications

Additional Information

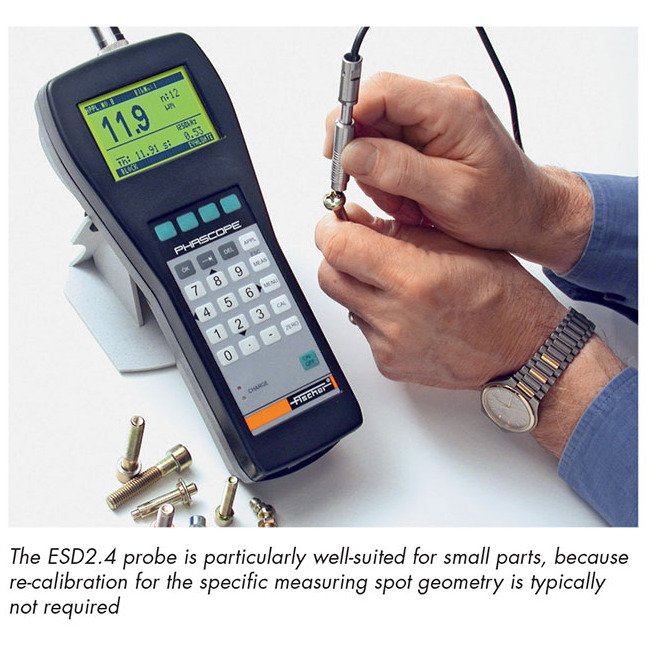

The ESD2.4 probe is particularly well-suited for small parts, because re-calibration for the specific measuring spot geometry is typically not requiredMeasuring copper thickness in through-holes using the ESL080B probeMeasuring on rough surfaces, Zn/Fe with the ESD20Zn probe

Applications

The phase-sensitive eddy current method offers great advantages in measuring small objects such as screws, nuts and bolts, since the geometry of the part being measured exerts very little influence on the measurement itself: Even rough surfaces can be measured precisely with the PHASCOPE® PMP10. This method also enables non-contact measuring; for example, the thickness of copper plating on a circuit board can be measured irrespective of protective lacquer coatings.Using specialized probes optimized for specific measurement tasks, the PHASCOPE® PMP10 is particularly suitable for the following:Measuring coating thickness of nickel on steelMeasuring zinc or copper on steel-despite rough surfaces and complex surface geometriesMeasuring the thickness of non-ferrous metals on non-ferrous metals, given sufficient difference in conductivity, e.g. copper on brass or bronzeMeasuring the thickness of non-ferrous metals on insulating substrates, such as copper layers on circuit boards.

Fischer Datacenter

Indispensable for the quick and easy transfer of data from the PHASCOPE® PMP10 to a computer, Fischer DataCenter software is a powerful tool that also offers extensive graphic display and statistical analysis functions for quality control: statistical process control charts, cumulative frequency diagrams and Fischer's own FDD® (factory diagnosis diagram). The built-in report editor enables measurement data to be conveniently processed, archived and printed out as individual inspection reports.

Instrument Features

Extensive evaluation and statistics functionsOutlier control and tolerance monitoring optionsVarious languages to choose fromBattery and/or continuous operation via plug-in charger (included)Data transfer via RS-232 interface

Specifications Intended Application

Coating Thickness

Specifications Storage Of Readings

0 to 20000