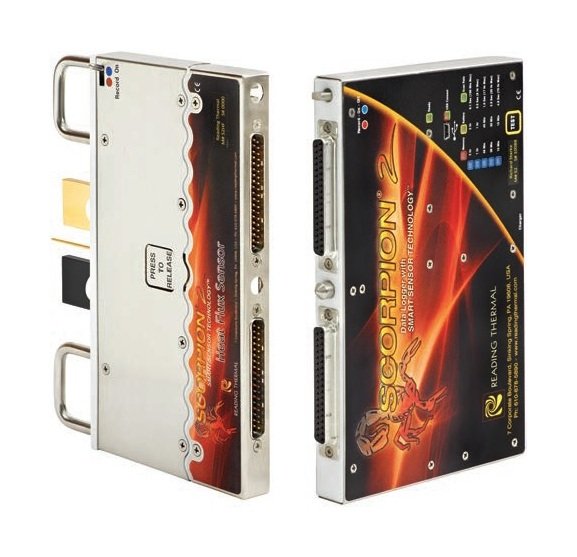

SCORPION® 2 Data Loggers with Smart Sensor Technology™ - Industrial Grade Temperature Monitoring System

SCORPION® 2 Data Loggers with Smart Sensor Technology™ - Industrial Grade Temperature Monitoring System

SKU:SCO-d41d8c

SCORPION® 2 Data Loggers with Smart Sensor Technology™ - Precision temperature monitoring for industrial applications.

Regular price

$899.99

Regular price

Sale price

$899.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The SCORPION® 2 Data Logger, equipped with Smart Sensor Technology™, is a sophisticated temperature monitoring system designed to capture and store data from up to 32 sensor/I channels at high speeds, ensuring precise measurement accuracy. This rugged device features non-volatile memory, a user-friendly interface for easy operation by line workers, and diverse applications in quality assurance, equipment performance analysis, food safety optimization, and new product development. With compliance to European Conformity (CE) standards, this industrial-grade system offers unparalleled efficiency and reliability for institutional and government procurement needs.

Product Specifications

Additional Information

Smart Sensor Technology™ allows the Data Logger to automatically recognize the attached sensor and perform a self-test. Each Smart Sensor™ contains embedded memory which is programmed during manufacturing. The embedded memory contains calibration data, date of calibration, sensor type, sensor serial number and date of manufacture.Smart sensors are attached to the data logger via two 32-Pin D-Sub Connectors and an easily-aligned self-latching mechanism. Multiple profiles can be collected with the same or different sensor without returning to a computer and downloading data between runs. When ready to download and analyze data the user simply starts the SCORPION® 2 Software (SV8) and connects the data logger to the computer via a USB cable.The SCORPION® 2 Data Logger contains an onboard User Interface which enables data collection without the need of a computer on the factory floor. Immediately upon connecting a Smart Sensor, a communication link is established between the data logger and sensor and a self-test is initiated. The result of this test is indicated by a Ready Light, allowing the user to confidently proceed with data collection knowing that all data logger and sensor parameters are within operational limits. Pressing the TEST button displays the Memory and Battery capacity, cautioning the user as the minimum amount of time remaining drops below two hours. The TEST button is also used to select a Scan Rate of 0.1, 0.5, 1, 2, or 4 seconds.

Applications

Quality AssuranceRecord your processing conditions when your product quality is within specification. Save these profiles for future reference as "target" conditions. Use the SPC function included in the software to establish upper and lower control limits for your process temperature, air velocity, heat flux and humidity profiles.Line Start-upTake a SCORPION® 2 profile a few minutes before introducing product into a process. This is a good check that the process has reached the correct operating conditions before production is started.Product Consistency Line-to-LineCompare SCORPION® 2 profiles for two process ovens, perhaps in different factories, that are supposed to be making the same product.Commissioning and MaintenanceHeat process ovens usually include dampers and other controls that must be set by the installation engineer. Use SCORPION® 2 to check that these have been set correctly. Repeat the profiles as part of your preventative maintenance program to detect drift in zone conditions and to pin-point the cause of problems when they do occur.Analyze Equipment PerformanceMost oven manufacturers now use SCORPION® 2 to design their heat processes. This is an invaluable tool for design engineers to balance heat and airflow across the width and along the length of the process oven.Optimize Food Safety and ThroughputControlling internal food temperature is key to achieving food safety. Today's food processors must also document how they are meeting food safety requirements with data. The SCORPION® 2 Data Logging Measurement System makes both jobs easier.The SCORPION® 2 Data Logger with R&D Smart Sensor and Product Probes simplifies the measurement of environment temperature, airflow, energy transfer and internal product core temperature. Plus the SCORPION® 2 Software (SV8) calculates and displays the % kill for a specified pathogen reduction level.By combining this ease of measurement with robust data capture, the SCORPION® 2 System enables better process optimization. No other system makes achieving desired levels of food safety and throughput so simple.New Product DevelopmentUse SCORPION® 2 to record the processing conditions you develop in the lab or in a pilot plant. Then use SCORPION® 2 again to establish the same conditions as the new product is transferred to a full-scale production line.

Output Channels Number Of Constant Current Sources For Air Veloc

3

Output Channels Regulated Output Voltage For Humidity Sensor Hea

5 V

Output Channels Regulated Output Voltage For Smart Sensor Memory

3.3 V

Output Channels Unregulated Output Voltage For Humidity Sensor H

7.2 V

Specifications Industry Standards

European Conformity (CE)

Technical Summary Accuracy

1.0 ºC | 1.8 ºF

Technical Summary Battery Capacity

2200 mA·h

Technical Summary Battery Running Time

50+ hour

Technical Summary Battery Voltage

7.2 V

Technical Summary Input Channels

32

Technical Summary Material

Rugged Stainless-Steel Enclosure

Technical Summary Maximum Memory Capacity

Up to 100 min at 0.1 sec Scan Rate | Up to 17 hrs at 1 sec Scan Rate | Up to 35 hrs at 2 sec Scan Rate | Up to 70 hrs at 4 sec Scan Rate | Up to 8 hrs at 0.5 sec Scan Rate

Technical Summary Memory Type

Non-Volatile Flash

Technical Summary Personal Computer Pc Communication Link

Universal Serial Bus (USB) 2.0

Technical Summary Resolution

0.025 ºC | 0.045 ºF

Technical Summary Scan Interval

0.1 second | 0.5 second | 1.0 second | 2.0 second | 4.0 second

Technical Summary Sensor Interface

32-Pin D-Sub Connectors

Technical Summary Time Tracking

Onboard Real Time Clock - Time / Date

Thermocouple Input Type Input Temperate Range

-260 to 1378 ºC | -436 to 2513 ºF

Thermocouple Input Type Optional Sensor Type

Type J Thermocouple | Type K Thermocouple

Thermocouple Input Type Sensor Type

Type T Thermocouple