Sullivan-Palatek® 630 CFM Variable Frequency Drive Air Compressor

Sullivan-Palatek® 630 CFM Variable Frequency Drive Air Compressor

SKU:SUL-bafbd7

Highly efficient Sullivan-Palatek® 630 CFM VFD Air Compressor with T1 control for precise operations.

Regular price

$15,999.99

Regular price

Sale price

$15,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Sullivan-Palatek® 630 CFM Variable Frequency Drive Air Compressor is a versatile solution designed with the highest standard in control using the advanced T1 microprocessor. With RS485 communication, precise power consumption data display, and a user-friendly interface, this compressor offers unparalleled compressor control. Featuring a durable build, 125 hp motor power, and exceptional flow rates at varying pressures, it ensures efficient and reliable compressed air supply for industrial operations, meeting the strictest standards for performance and quality.

Product Specifications

Additional Information 0

The T1 will control your specific compressed air needs as the system requires, and will conserve your power when the compressed air need is reduced.Today's controllers are much more powerful and versatile than prior models. The amazing T-1 Microprocessor is the brains behind our VFD compressors - which allows you to program your daily operation schedule and shut off during factory shutdown up to 28 different times per week!The built in sequencer will control up to seven VFD or NON-VFD compressors with the VFD compressor as the trim machine! And you can configure the display with any one of twenty operational readings - while still showing the always-visible dedicated pressure display!Wide power range for 200 V, 230 V, 460 V and 575 V.Pressure transducer motor speed control, provided by pressure signal via our T1 microprocessor control.Programmable digital outputs available.Digital inputs from 2 pressure sensors, and a temperature sensor.8 programmable parameter sets with S-curves, power off function, PID process controller, electronic motor protection and internal timer. Output frequencies up to 160 Hz with output voltage stabilization; switching frequencies up to 16 kHz; output phase monitoring.DC bus circuit connection and motor thermal sensor connection are provided.All new Platinum and Platinum-Plus Warranties available.

Dimensions Height Enclosed

67 in

Dimensions Height Open

66 in

Dimensions Length Enclosed

120 in

Dimensions Length Open

120 in

Dimensions Width Enclosed

58 in

Dimensions Width Open

58 in

Energy Costs 0

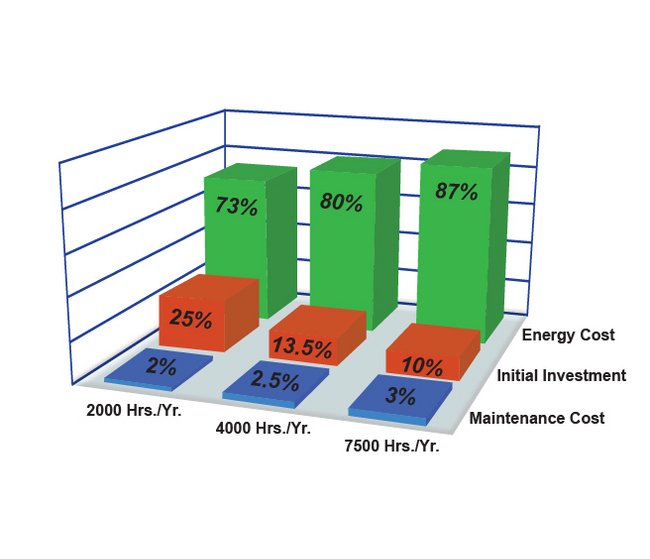

Based on 7500 Hours a Year, 87% of the Cost of Ownership for Your Compressor is ENERGY.This chart is based on a power cost of 8 cents per Kwh. Depreciation cost is rated at 5 years at 8% interest.

Note 0

The Ultimate Performance Rotary Screw Air Compressor.

Operating Cost Savings Over Time 0

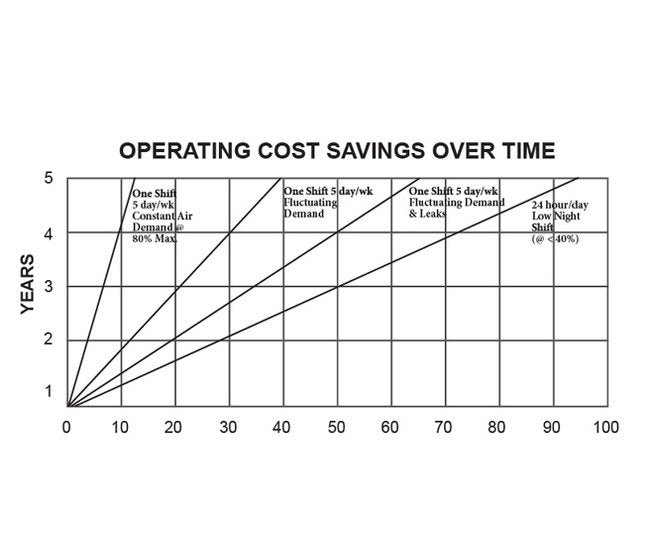

The Cost Savings Chart illustrates the reduced operating cost of a VFD Unit by correcting poor air usage: Five day/week operation, erratic demand fluctuations (28% of installations), steady weekend consumption with leaks (64% of installations). This shows 24 hour operation with low night shift and high day shift consumption at more than 40% savings after 5 years. In many instances the VFD Compressor will have a payback of the additional cost within 2 1/2 to 3 years.

Product Information Business Tax Incentives

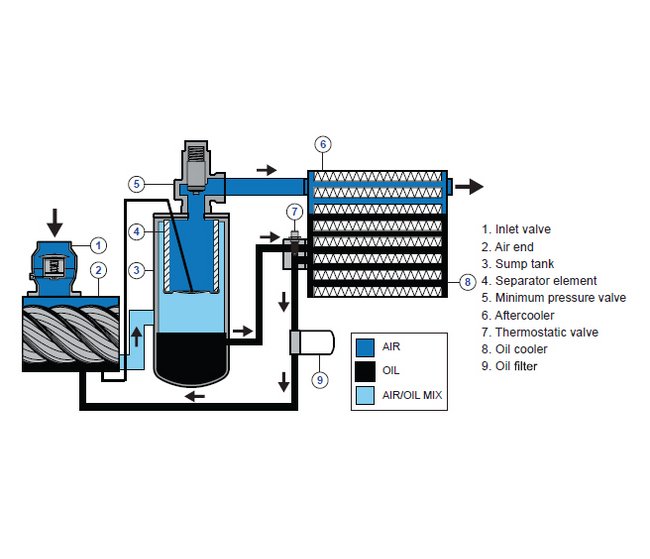

Advanced Energy Manufacturing Tax Credit ("MTC")The American Recovery and Reinvestment Act of 2009: 1. ("Recovery Act") amended or added numerous energy tax incentives available to businesses, utilities, and government. Many of these incentives were previously modified by Emergency Economic Stabilization Act in 2008: 2. The majority of the incentives were originally passed into law under the Energy Policy Act of 2005 (EPACT): 3. The Recovery Act also provided additional tax incentives for consumers.In addition to government tax incentives, some local utility companies also have rebate plans or incentives.Air is drawn through the air filter and inlet valve (1), into the air end (2). The air mixes with oil as the rotors in the air end (2) compress it. After compression, the oil and air mixture is discharged into the sump tank (3). Inside the sump tank (3), the bulk of the oil is separated from the air by change of direction and reduction of velocity. The air passes through a separator element (4) housed in the sump tank (3) to remove any remaining oil. When air pressure builds to 60 psi, the minimum pressure valve (5) opens and allows the separated air to enter the aftercooler (6). After being cooled, the air is delivered to the system for use. Oil that was removed from the air by the separator element (4) collects in the bottom of the element. A scavenger line removes the oil collected in the bottom of the separator element, passes it through a sight glass (containing a screen and an orifice), and injects it directly into the air end.

Product Information Operating Efficiency

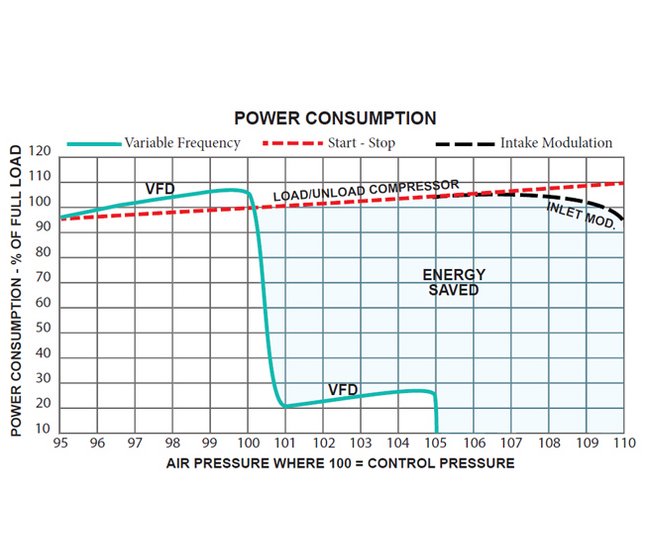

The Power Consumption Efficiency Curve Chart shows how the Variable Frequency Drive operates more efficiently than other controls in providing air delivery. The VFD helps reduce energy bills. Operating at 70% capacity, the VFD consumes 25% less power than a standard compressor operating with on-off control and 20% less than a compressor with modulating control. The Variable Frequency Drive has a soft start feature that maintains a low starting current (see start-up chart on page 3). This reduces the stress on the site power supply and also reduces motor wear. The VFD system complies with the electromagnetic compatibility standard and is CSA listed. The VFD system is not limited to a fixed number of starts per hour.

Product Information Practical Operation

The specific operating pressure needed to allow correct plant operation needs to be determined. The VFD Lead should be set up so the needed pressure is midway between the load and unload settings. The Lags should have their modulation regulator set so there is minimal modulation. The whole system will operate as efficiently as a VFD will, and thus it should not modulate until it is at this pressure to unload pressure. The VFD Lead will do a good job of maintaining the needed pressure, and therefore, it does not need to be set higher than needed. The Lead has PI control functions in it which will help to stabilize the control in changing conditions. The Lead's pressure schedule can also be used to totally shut down the system at certain times of the day or week, or to reduce the system pressure for those times of the day when less air (CFM) is needed for normal operation.

Product Information Save Money

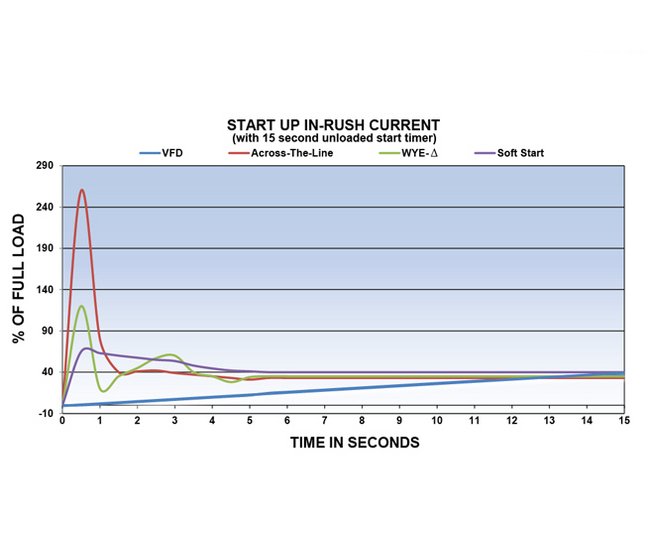

Please note from the graph below that the VFD will not draw the in-rush current that other starters will require. This means that starting the VFD compressor will not incur the penalty payments charged by power companies for momentary very high current draw associated with other starting methods.

Product Information Sequencer Operation Principles

The VFD compressor serves as the "Lead" machine. It runs at the speed needed to supply the necessary air pressure, and calls on the other "Lag" compressors to run when required. If there is more than one Lag, the Lead will determine which one is next up, and how many are needed to supply the right amount of air to the plant. The Lead should be close to the same size or larger than the Lags so they don't suddenly over-pressure the system. Normally the VFD maintains tight pressure control unless the air demand is low enough to reach the unload pressure. In this case it will maintain the pressure midway between the load and unload pressures. It attempts to maintain this, but will speed up or slowdown to maintain this midpoint pressure, while adding or taking off Lags to maintain the desired pressure range. If it can't keep up, it will call on the next Lag to help, and slow down to trim to the demand. When it has slowed to its minimum speed, it will send the Lag into unload and to off, and will speed up to maintain the pressure. If the demand drops to zero, the Lead will also sleep and go to a standby mode.

Specifications Brand

Sullivan-Palatek®

Specifications Compressed Air Accessories

Air Filters | Air System Analysis | Condensate Management Systems | Desiccant Air Dryers | Oil Free Systems | Refrigerated Air Dryers | System Management Solutions

Specifications Diesel Driven Portable Air Compressors

185 to 1800 cfm | 3 Year Air End Warranty | John Deere, Caterpillar and Cummins Engines | Offshore Models | Utility Models

Specifications Electric Driven Industrial Air Compressors

15 to 40 hp Direct Drive | 40 to 400 hp Up-Draft | 5 to 10 hp Belt Driven | High and Low Pressure | Specialty Packaged Systems | Variable Frequency Drive Designs

Specifications High Pressure Portable And Skid

900/350 to 1150/350

Specifications Industry Standards

AEM Member | CAGI Compressed Air and Gas Institute® | I Make America

Specifications Instrument Quality Air

375H to 1600H | Construction Electric 50 to 400 HP | Electronic Parts Orders Through | Full Line of Pneumatic Tools | Hoses and Accessories | Skid Mount Aftercoolers | Skid Mount Dryers and Aftercoolers | SmartEquip™

Specifications Maximum Flow At Control Pressure 100 Psig Rating

630 ft³/min

Specifications Maximum Flow At Control Pressure 125 Psig Rating

555 ft³/min

Specifications Maximum Flow At Control Pressure 150 Psig Rating

495 ft³/min

Specifications Motor Power

125 hp

Specifications Piston Air Compressors

Gas Driven | Pressure Lube | Splash Lube

Specifications Voltage

200 V | 230 V | 460 V | 575 V

Specifications Weight

5000 lb

Specifications Weight Open

4500 lb

Standard Features Cooling System Up Draft Model

Cooling system with Independent V1000 Variable Frequency Drive. Large side-by-side oil cooler and aftercooler for easy cleaning.

Standard Features Coupling And Drive

Compressor is flange mounted to motor C-face for positive alignment and direct driven.

Standard Features Main Motor Variable Frequency Drive Vfd

The A1000 Drive is factory programmed and ready to run.Designed for tough industrial environments.Performance Features:150% overload for 1 minute heavy-duty150% starting torque at 1 HZAdjustable acceleration/decelerationStall preventionSelectable auto restart after momentary power loss

Standard Features Note For Cooling System Up Draft Model

Up-Draft Cooling, Vertical.

Standard Features Variable Frequency Drive Vfd Fan Motor

Ensures optimum air flow for proper temperature control. Increased energy savings on fan motor during low RPM compressor operation.Safety shutdown feature is enabled when cooling fan power is interrupted.All compressors are built with air cooled oil coolers and aftercoolers as standard, unless water cooled oil coolers and aftercoolers are requested.Optional Equipment Choices for all Sullivan-Palatek® compressors are available.

T1 Variable Frequency Drive Vfd Microprocessor Analog Output

Possible usages for:Pressure or temperature on inline.Temperature display on up-drafts.

T1 Variable Frequency Drive Vfd Microprocessor Built In Sequence

Will trim up to 7 VFD or NON-VFD machines with microprocessor controls.

T1 Variable Frequency Drive Vfd Microprocessor Digital Output

Drain timesExact set pressureLoad and unload pressuresModbus addressPower failure auto restartShut down for excessive temperature or pressureStop run on timeTime for unloaded start

T1 Variable Frequency Drive Vfd Microprocessor Dual Function E S

For direct shutdown of VFD and T1.

T1 Variable Frequency Drive Vfd Microprocessor Eleven Different

Compressor Status ~ Differential Pressure ~ Drive Fault ~ Drive Temperature ~ Motor Current ~ Motor Speed ~ Percent Capacity ~ Power Used ~ Run or Loaded Hours ~ Service Time Remaining ~ Compressor Operating Temperature.