1/2" Platinum GFPP Simplex Basket Strainer with FPM O-Rings

1/2" Platinum GFPP Simplex Basket Strainer with FPM O-Rings

SKU:STR-f31752

Efficiently protect system components with our 1/2" Platinum GFPP Simplex Basket Strainer threaded for easy installation. Reliable performance guaranteed.

Regular price

$45.99

Regular price

Sale price

$45.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The 1/2" Platinum GFPP Simplex Basket Strainer with FPM O-Rings is designed to protect vital system components by effectively filtering out dirt and debris. Featuring a threaded connection type and high-quality seals, this strainer ensures optimal performance and minimal maintenance downtime. With precise dimensions and a robust body material, it meets stringent industry standards for reliability and durability. Ideal for applications requiring efficient particle removal and easy cleaning, this strainer is a top choice for institutional and government buyers seeking premium filtration solutions.

Product Specifications

Additional Information Additional Information

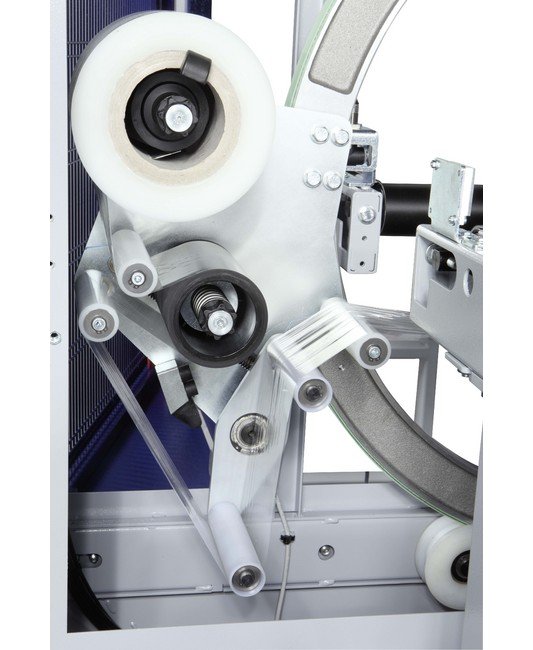

Robopac® leads the industry with innovative products and solutions. The new Orbit machines prove that we are committed to providing you with the best machines combined with the latest technology. Our engineers wouldnât allow us to do it any other way.Built for Rugged OperationsSafe & Simple OperationDoesn't Cause Product DamageWarranty/Extended WarrantyConveyor Infeed & OutfeedAutomatic Cycle StartIcon Driven Color Touchscreen

Color Touch Screen Color Touch Screen

The new 7-inch, 65,000 color touch screen provides complete control of all processes with the touch of a finger. Accurate, easy to understand controls are displayed on every screen allowing for quick and simple operation. Store up to 20 unique, user-defined wrapping programs.Adjustments capable via touchscreen:ParametersNumber of wrapsWrapping start timeWrapping end timeCyclesTotal WrappingHead and tail wrappingBand wrappingWrapping with reinforcementBy-passPushbutton CommandsEmergency/Stop push buttonReset buttonStart cycle buttonStop cycle buttonWrapping MenuColor display clearly shows available wrapping options. The touchscreen makes selecting a wrapping pattern simple and provides immediate visual confirmation of selected pattern.

Film Specifications Film Width

2 to 5 in

Film Specifications Maximum Spool External Diameter

8 in

Innovative Features Automatic Cut And Clamp Unit

Highly reliable, dual rod cut and clamp system fully automates the wrapping process.

Innovative Features Guides

Infeed and outfeed skid side guides can be manually adjusted to better center products of variable widths. Idle rollers allow products to convey smoothly during the entire wrapping process.

Innovative Features Pneumatic Top Platens

Infeed and outfeed units automatically adjust to ensure proper stabilization of the product. The length of the run can be adjusted manually, if needed, to compensate for products of varying height.

Innovative Features Ring

Single-cast aluminum ring provides strength and reliability.

Machine Dimensions Height

69 in

Machine Dimensions Height1

31.5 to 36 in

Machine Dimensions Length

78 in

Machine Dimensions Width

57.5 in

Minimum Workable Dimensions Minimum Workable Dimensions

2-3/4 x 2-3/4 in

Minimum Workable Dimensions Note For Minimum Workable Dimensions

Dimensions refer to infeed with conveyor belts on rollers. For other types of conveyors, maximum workable dimensions will be provided by Robopac®.

Optimal Wrapping Condition Optimal Wrapping Condition

For best results while wrapping the load, the center of the Orbit rotating ring must fall within the product pro?le as shown. Orbit machines allow you to adjust the height of the conveyor, except the Orbit 4, which is fixed.

Safety Safety

Robopac® understands the importance of plant safety in todayâs manufacturing environment. Our engineers have incorporated features designed to reduce possible injuries while maintaining the highest possible output.Every unit features electro-welded mesh doors that provide easy access for machine maintenance. Each door is equipped with a safety micro switch that prohibits machine operation if open to guarantee operator safety.

Specifications Type

Stretch

Technical Features Compressed Air Consumption

5 NI/Cycle

Technical Features Constant Film Tensioning

Yes

Technical Features Core Diameter

3 in

Technical Features Frequency

50 Hz | 60 Hz

Technical Features Fully Automatic Wrapping Cycle

Yes

Technical Features Installed Power

1.5 hp | 1.1 kW

Technical Features Maximum External Diameter

8 in

Technical Features Maximum Rotation Speed

120 rpm

Technical Features Phase

3

Technical Features Pneumatically Operated Cold Cutting And Clamp

Yes

Technical Features Pneumatic Cold Cutting And Clamping Unit

Standard

Technical Features Pneumatic Pressure Units For Infeed And Outfe

Standard

Technical Features Powered Conveyors For Infeed And Outfeed

24 in | 600 mm

Technical Features Power Supply Voltage

480 V

Technical Features Power Transmission

Belt Driven Rotation

Technical Features Pre Stretch

Friction Roll

Technical Features Spool Unit With Frictioned Roll

Yes

Technical Features Working Pressure

90 psi | 6 bar

Technical Features Working Pressure Tolerance

1 bar

Technical Features Wrapping Cycle

Banding | Fully Automatic | Head-Tail Only

Wrapping Dimensions Wrapping Dimensions

Maximum product width and height dimensions directly affect each other. As the maximum product width increases the maximum product height decreases; as well, when the maximum product width decreases the maximum product height increases as the charts above show. Adjusting the conveyor height also affects the maximum height and width of the product. Orbit machines allow you to adjust the height of the conveyor, except the Orbit 4, which is fixed.