3/4" PVC Simplex Basket Strainers with EPDM Seal, Flanged End Connections - SB Series

3/4" PVC Simplex Basket Strainers with EPDM Seal, Flanged End Connections - SB Series

SKU:BAG-6d3a2d

Protect your system components with the 3/4" PVC Simplex Basket Strainer featuring EPDM seal and flanged end connections. Ensure debris-free flow!

Regular price

$89.99

Regular price

Sale price

$89.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The 3/4" PVC Simplex Basket Strainer from the SB Series offers unparalleled protection for pipeline system components. Featuring an EPDM seal and flanged end connections, this strainer effectively removes unwanted particles with a 1/32" standard basket perf. Designed for durability and efficiency, it boasts a high flow coefficient of 18.0 and meets rigorous industry standards. Ideal for applications requiring reliable dirt and debris filtration.

Product Specifications

Additional Information Additional Information

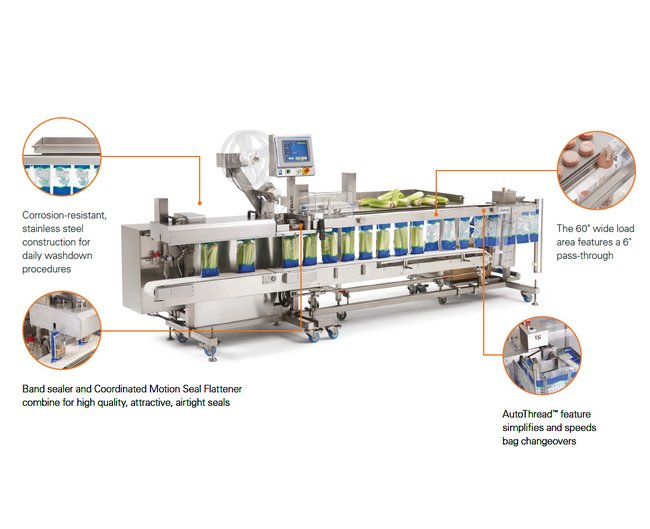

Engineered to satisfy high-productivity requirements, the FAS SPrint Revolution⢠presents a conveyor of pre-opened bags that are staged for immediate loading. The 60" wide load area features a 6" pass-through, and tilts vertically for easy maintenance and sanitation. An innovative Coordinated Motion Seal Flattener is coupled with a band sealing system to ensure high quality, airtight, 3/8" bag seals. The system operates in continuous, intermittent or batch modes, and cycles on pre-set parameters, or manually with a footswitch. This highly flexible design accommodates one or more operators or infeeds and a wide variety of products and bag sizes.An integrated Allen-Bradley® control package, featuring Kinetix® Servo motors and drives, a CompactLogix⢠L45 PLC, and a large, 10" PanelView⢠Plus HMI, is designed for ease of operation, serviceability, integration, and overall system reliability. Programming of all components is done with a simple flash card. The AutoTouch⢠Control Software displays real time productivity data and provides easy access to job storage, job recall and on-board system diagnostics.Genuine SidePouch® bags are system-matched for optimum performance, and offer a variety of value-added features, such as reclosable zippers, resealable flaps and tamper-evident perforations. Since the bags are pre-made, costly machine modifications are not needed to utilize these features. SidePouch® bags are available in an assortment of materials that can be pre-printed in up to 10-colors with high-resolution graphics, text and bar codes for unique, attractive packaging with a competitive edge.

Electrical Specifications Alternating Current Ac Voltage

110 V | 230 V

Features And Benefits Features And Benefits

FlexibleAccommodates a wide variety of loading methods, automatic infeeds, inline imprinters, products and bag sizesMulti-DimensionalRuns laminated stand-up pouches and regular poly bags interchangeablyReliableIntegrated Allen-Bradley® control package for reliabilityEasy RecallOn-board memory stores data for up to 25 jobsEasy LoadingAutoThread⢠feature simplifies and speeds bag changeoversWashdown CapabilityIP65 rated, with NEMA 4x enclosures for safe operationMobileStandard casters for easy movementSanitary DesignMajor assemblies rotate to simplify cleaning and maintenanceIntuitive InterfaceState of the art controls and operator-friendly AutoTouch⢠Control Software simplify user experience

Mechanical Features Mechanical Features

Corrosion-resistant, stainless steel construction for daily washdown proceduresBand sealer and Coordinated Motion Seal Flattener combine for high quality, attractive, airtight sealsThe 60" wide load area features a 6" pass-throughAutoThread⢠feature simplifies and speeds bag changeovers

Optional Additions Optional Additions

Washdown-Compatible Inline ImprinterProduct Load TableProduct Support ConveyorBag DeflationTie-in Kits for Auxiliary InfeedsAdditional Operator Footswitches (Up to Two)Positive Entry Dunk FunnelsSpare Parts KitsCustom Engineering & Integration Design and Support

Specifications Current

12 A | 6 A

Specifications Frequency

50 Hz | 60 Hz

Specifications Markets Served

Fresh and Dried Pastas | Fresh and Frozen Snack Foods | Fresh Whole and Cut Produce | Frozen and IQF Food Products | Meat, Poultry, Fish and Meat by-products | Medical, Automotive, and Mail Order Fulfillment | Pet Food Products

Specifications Weight

1134 lb

Technical Information Air Feed At 80 Pound Per Square Inch Psi O

5 cfm

Technical Information Bag Length

3 to 18.75 in

Technical Information Bag Thickness

1.32 to 4.0 mil

Technical Information Bag Width

2 to 20 in

Technical Information Height

63 in

Technical Information Length

148 in

Technical Information Pass Through

0 to 6 in

Technical Information Weight Capacity With Support Conveyor Per

0 to 15 lb

Technical Information Width

47 in