75LTW-24SS Tray Shrink Wrapping Machine

75LTW-24SS Tray Shrink Wrapping Machine

SKU:TRA-de0ba5

Highly durable 75LTW-24SS Tray Shrink Wrapping Machine for 24/7 operation, featuring precision components, digital controls, and efficient maintenance.

Regular price

$29,999.00

Regular price

Sale price

$29,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The 75LTW-24SS Continuous Motion Tray Shrink Wrapping Machine is a heavy-duty solution designed for high durability and 24/7 operation. It features laser-cut and CNC-machined components for precision, a powder coat finish for scratch resistance, and a compact single-frame design with an integrated tunnel. Equipped with an Allen-Bradley® PanelView Plus 600 operator interface, this machine offers digital controls for efficient setup, a bypass mode, low film alert, and durable Intralox conveyor belts. With a dual-zone shrink tunnel, NEMA 12 electrical cabinet, and central point lubrication, maintenance is simplified for continuous use.

Product Specifications

Electrical Power Requirements Alternating Current Ac Voltage

460 V

Electrical Power Requirements Current

30 A

Electrical Power Requirements Frequency

60 Hz

Electrical Power Requirements Note

Specifications and product sizes may vary, depending upon the application.

Electrical Power Requirements Number Of Phase

3

Electrical Power Requirements Power

28 kW

Features Features

Digital controls ensure fast and accurate setup of conveyor speeds, timing, and temperature settings when changing product size and filmBypass mode allows product to pass through the machine without being wrapped and without heating the tunnelLow film alert warns that a film changeover will soon be necessaryDurable Intralox conveyor belts eliminate tracking issuesSeal frame opening for 10" tall productDual stage belt infeed conveyor20" diameter inline film racks for easy film loadingSimple film threading procedure93" dual zone shrink tunnel3-way cooling feature at the tunnel exit for immediate product handlingNEMA 12 electrical cabinet and controlsCentral point lubrication simplifies preventive maintenance

Options Options

Casters for machine portabilityQuick-change seal cylinder kit for higher speedsJib crane to assist with film loadingSide mounted film rack with manual splicing bar for easy film loading at slower speedsSide mounted film rack with manual film splicing bar and continuous film feed for easy film loading at standard operating speeds13 product opening for taller productsPrint registration - top film only16" high product (max speed 45 bundles per minute)Wider products and film widths: 75LTW-32 with 30" film and 75LTW-36 with 34" filmSeal gap bridge, roller or telescoping, for product 3"-5" long

Specifications Applications

Bottles | Cans | Jars | Single-Tier or Stacked Arrangement | Trayed boxes | Unitized Boxes

Specifications Conveyor Height

34 in

Specifications Conveyor Height Tolerance

+2 in | -0 in

Specifications Film Type

Low Density Polyethylene (L.D.P.E.)

Specifications Finish

Powder Coat

Specifications Height

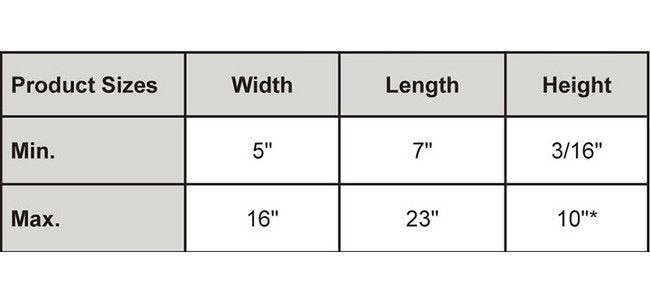

3/16 to 10 in

Specifications Inline Film Rack Diameter

20 in

Specifications Length

7 to 23 in

Specifications Machine Length

14 ft 9 in.

Specifications Machine Width

4 ft 8 in.

Specifications Maximum Film Gauge

1.5 mil

Specifications Maximum Film Roll Diameter

14 in

Specifications Maximum Film Roll Width

23 in

Specifications Pneumatic Requirement At 40 Standard Cubic Feet P

80 psi

Specifications Print Type

Clear or Randomly

Specifications Shrink Tunnel Size

93 in

Specifications Speed

Up to 75 trays per minute

Specifications Standards

NEMA 12

Specifications Width

5 to 16 in