ABC Packaging Model 101 Pick and Place Packers/Unpackers

ABC Packaging Model 101 Pick and Place Packers/Unpackers

SKU:MAC-42790c

Upgrade your packaging efficiency with ABC's Model 101 Pick and Place Packers/Unpackers - precise handling with top performance.

Regular price

$15,699.99

Regular price

Sale price

$15,699.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

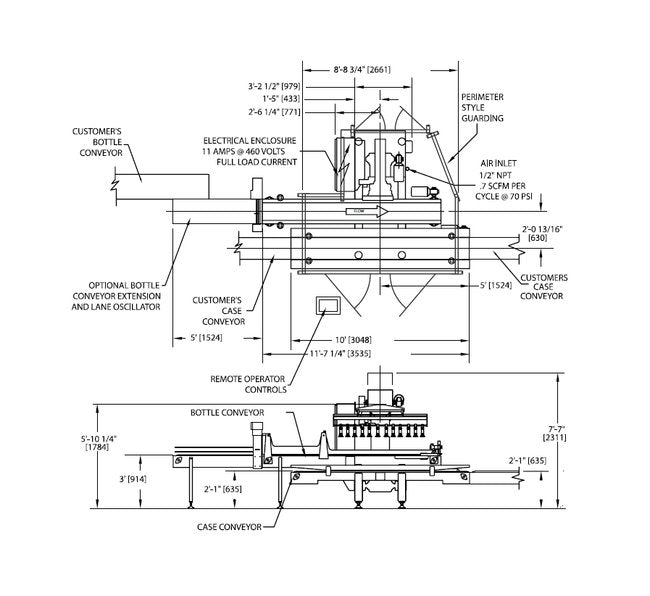

The ABC Packaging Model 101 Pick and Place Packers/Unpackers are precision-engineered secondary packaging machines designed for seamless case packing and uncasing of glass, plastic containers, cans, and cartons. With synchronized servo operation ensuring precise container handling from conveyor to case, these machines offer gentle product treatment, reducing breakage risk for glass and enhancing bottle stability for plastics. The robotic motion and intelligent control system guarantee top-tier performance, while non-contact sensors and PLC-controlled actions provide instant responses to varying conditions. The quick changeover design, compact yet sturdy steel frame, and versatile features ensure optimal container integrity while maintaining high efficiency.

Product Specifications

Features Features

Robotic motion provides gentle handlingServo operation provides precise handling, ensuring label and container integrityNO DROP - containers are released only upon contact with case or conveyor:Improved bottle stability when handling lightweight plastic containersReduced risk of breakage when handling glassGentle handling of heavy, industrial-sized containersAllows the option to 'thinwall' containers without sacrificing packaging performanceIntelligent Control for top performanceNon-contact sensors monitor machine operation, providing instant response to changing conditionsAll machine actions are controlled by PLC for precise operationRobot head is programmed to travel the shortest path from case to conveyor and back, for maximum efficiencyTouch screen panel gives you total controlThe touch screen control panel puts real-time operating data at your fingertips and offers simple, request-confirm sequences for revising production parameters or machine diagnostics. All functions may be operated independently from the touch screen, with return to automatic operation at any time.Designed for quick changeoverTo facilitate the fastest changeover for every customer, A-B-C provides complete gripper assemblies or an adjustable head, depending on the application. Guide rails are adjusted by locking slides.Changeover settings are completed at the touchscreen control panel by simply choosing the new container size.ReliableVersatile with quick changeoverFeatures to ensure container integrityCompact design

Note Note

All information in this brochure was current at time of printing, however, in the continuing effort to improve the quality and construction of A-B-C equipment, we reserve the right to make changes without notice.

Quality Features Quality Features

Heavy gauge steel frameIntelligent Control (PLC) of all machine functionsSolid state proximity sensors with quick disconnect fittingsPhoto eyes with background suppressionColor touchscreen control panelManual operation of all functionsSEW Eurodrive® motor for main horizontal movementServo motor for vertical head movementVFD control of A/C motors

Specifications Brand

ABC Packaging