ABC Packaging Model 156 High-Speed Decaser

ABC Packaging Model 156 High-Speed Decaser

SKU:MAC-bc36c4

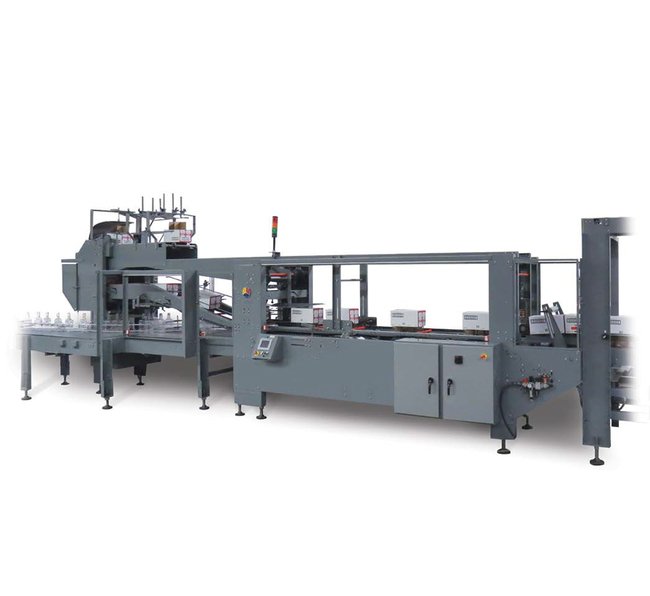

ABC Packaging Model 156 High-Speed Decaser - Streamline your packaging process with efficiency and precision.

Regular price

$34,999.00

Regular price

Sale price

$34,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The ABC Packaging Model 156 Decaser is a versatile workhorse designed to streamline your packaging process. With the ability to open cases, unload containers, and single-file them in a continuous, high-speed operation, this machine eliminates hand labor and reduces production costs. Ensuring a consistent container supply to the filler, it maintains top container integrity for lightweight plastic or irregular shapes like ovals and flasks. Featuring a solid channel steel frame construction and Allen-Bradley PLC monitoring, this decaser offers ergonomic advantages by automating tasks that would otherwise risk employee injury. With optional features like quick changeover packages, full case inverters, and empty case discharge, it provides flexibility for various production needs.

Product Specifications

Electrical Specifications Frequency

60 Hz

Electrical Specifications Industry Standards

National Electrical Manufacturers Association (NEMA 12)

Electrical Specifications Number Of Phase

3

Electrical Specifications Primary Voltage

230 V | 460 V

Features Features

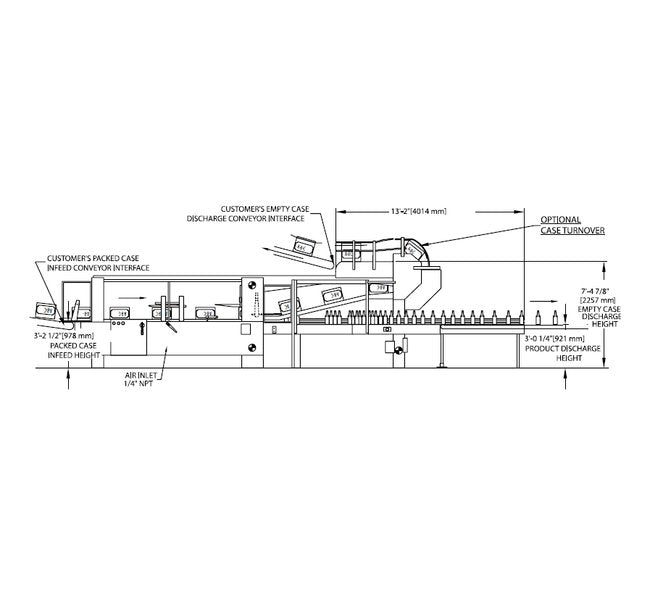

Ensure a consistent container supplyCases are automatically timed into the decaser from back-to-back or spaced conveyor orientation-no special infeed conveyor is required.Cases may feed from line or ceiling height (optional case inverter shown at left conveying cases from ceiling height.)Replace labor and liabilityThis decaser offers ergonomic advantages by eliminating the risk of employee injury or disability. No more repeated lifting and dumping empty bottles to feed the production line.It mechanically opens all four flaps, unloads and single files the containers, and uprights the empty cases for transfer to packing-automatically.Gentle No-Drop bottle handlingAfter all four flaps are opened, the case is conveyed upward and the containers glide to the transfer table. They remain in their pack pattern, spaced and separated, until single filed with minimum container contact.This technique reduces the risk of breakage when running glass, and minimizes the risk of downed bottles when running unstable lightweight plastic.Run many container stylesRound, non-round, oval, flasks and special shapesWide variety of heightsLightweight plasticSmall and lightweight glass

Note Note

All information in this brochure was current at time of printing, however, in the continuing effort to improve the quality and construction of A-B-C equipment, we reserve the right to make changes without notice.

Optional Features Optional Features

Quick changeover package180º Full Case Inverter at case infeed180º Empty Case Discharge- maintains four flap control

Quality Features Quality Features

Solid channel steel frame constructionAllen-Bradley PLC monitors line and controls operationAutomatic case timing at infeedAll-mechanical flight bar drive for case transferMechanical four flap openerIn-line empty case dischargeRight or left hand container dischargeClear sliding guard panels - allow easy machine access

Specifications Brand

ABC Packaging

Specifications Case Style

Half Slotted Case (HSC) | Regular Slotted Case (RSC)

Specifications Mechanical Motor Power

3 hp

Specifications Speed

Up to 50 cases/min