ABC Packaging Model 49 Case Decasers

ABC Packaging Model 49 Case Decasers

SKU:MAC-08b7e5

Efficiently unload reshipper cases with the ABC Packaging Model 49 Case Decasers. Enhance productivity and safety in your production line.

Regular price

$34,999.00

Regular price

Sale price

$34,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The ABC Packaging Model 49 Case Decasers offer a compact and efficient solution for high-speed unloading of reshipper cases, ensuring a continuous supply of empty bottles to your production line. With a versatile design that accommodates various case styles and a speed of up to 70 cases/min, this machine eliminates manual case unloading, providing gentle container handling and positive empty case transport. Its quality features such as steel frame construction, Allen-Bradley PLC monitoring, and quick changeover capabilities make it a reliable choice for industrial operations.

Product Specifications

Electrical Specifications Frequency

60 Hz

Electrical Specifications Number Of Phase

3

Electrical Specifications Primary Voltage

220 V | 440 V

Features Features

High speed, in-line operationThe Model 49 eliminates the repetitive tasks associated with manual decasing, eliminating the risk of employee injury or disability.Cases feed back-to-back through a vertical belt infeed which provides gentle case handling. Major flaps are plowed open and the minor flaps are opened by the bottle weight as the case is lifted. The bottles discharge onto the impact absorbing belt.Gentle container handlingAs the bottles discharge, they remain spaced and separated in their pack pattern until they reach single filing.The single filing section is designed to separate the bottles with minimum bottle-to-bottle contact. This reduces the risk of breakage when running glass, and the risk of downed bottles when running plastic containers.Line layout flexibilityThe Model 49 has a compact design, providing maximum flexibility for line layouts. Right hand or left hand bottle discharge is available.Empty cases are up righted and discharged onto a floor level conveyor. The optional 180º case turnover cycles cases for ceiling height transport.Versatile for many container stylesThe Model 49 automatically decases and single files glass or plastic bottles from RSC, HSC, or Tablock cases. Changeover is quick and easy...most case changes are completed with simple hand crank adjustments.Ensure container integrityEliminate labor and liabilityRun many styles with quick changeover

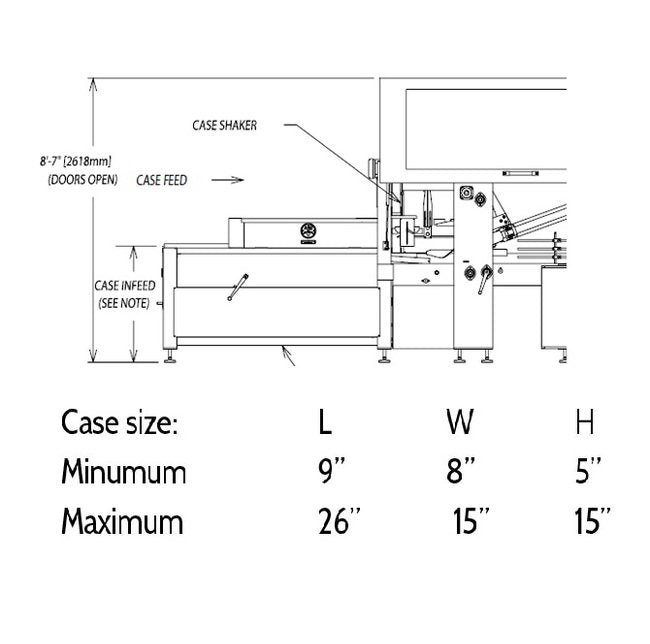

Machine Dimensions Machine Height

6 ft 2 in.

Machine Dimensions Machine Length

19 ft 10 in.

Machine Dimensions Machine Width

5 ft 2 in.

Note Note

All information in this brochure was current at time of printing, however, in the continuing effort to improve the quality and construction of A-B-C equipment, we reserve the right to make changes without notice.

Quality Features Quality Features

Steel frame constructionAllen-Bradley PLC monitors line and controls operationVertical belt infeed for gentle case handlingQuick changeover with rapid adjust hand cranks for new case sizesVariable speed drive to meet production needsLocking side bar adjustmentsOptional repeatable position indicators

Specifications Brand

ABC Packaging

Specifications Case Style

Half Slotted Case (HSC) | Regular Slotted Case (RSC) | Regular Slotted Case (RSC) with Tablock

Specifications Speed

Up to 70 cases/min

Specifications Weight

3590 lb

Specifications Weight With 180 Degree Case Turnover

4020 lb