Acrolab Custom Isobar Heat Pipes

Acrolab Custom Isobar Heat Pipes

SKU:ISO-924644

Efficiently transfer energy with Acrolab Custom Isobar Heat Pipes, ensuring precise thermal management for various applications.

Regular price

$899.99

Regular price

Sale price

$899.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Acrolab's Custom Isobar Heat Pipes are expertly designed for a wide range of applications, providing efficient thermal management solutions. These Isobar® Heat Pipes transfer large amounts of energy with precision and speed, offering near-isothermal conditions and uniform temperature distribution. The advanced technology ensures optimal thermal conductivity, making them superior to traditional conductors like aluminum and copper. With customizable designs and a variety of working fluids to choose from, Acrolab's Isobar Heat Pipes are the ideal choice for meeting diverse heating, cooling, and thermal uniformity needs.

Product Specifications

Additional Information

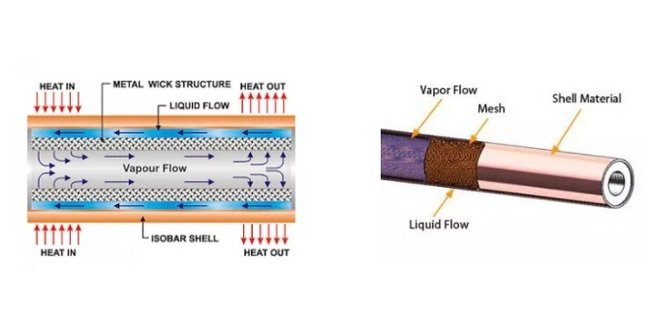

Heat pipes offer thermal conductivity that can range from 5,000 W/m·K to 100,000 W/m·K, making them far superior to solid aluminum, copper and graphite conductors.Typical Arcolab Isobar Heat Pipes have 3 sections;Evaporator SectionAdiabatic SectionCondenser SectionAcrolab heat pipes or, vessels, are constructed with a tight vacuum seal that contain a working fluid and a wick structure acting as a capillary. They utilize the vaporization of an inner fluid to transfer heat to the heat sink [3) Condenser Section] from the heat source [1) Evaporator Section] over the distance of the 2) Adiabatic Section.Isobar heat pipes are sealed and fluid constantly changes phase due to the low vapor pressure inside the unit - the device is innately isothermal.Temperature uniformity along the entire length from the evaporator to the condenser is typically in the range of ±1°C while transferring large amounts of energy.

Features

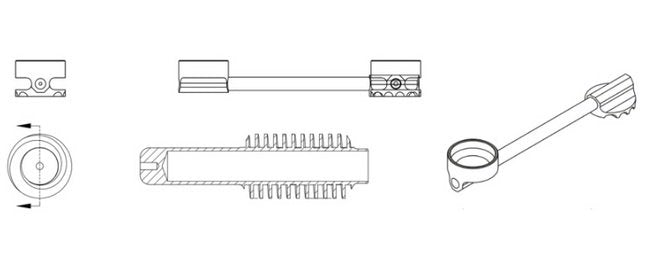

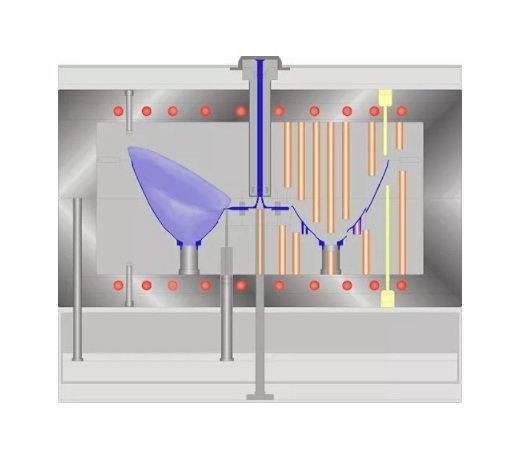

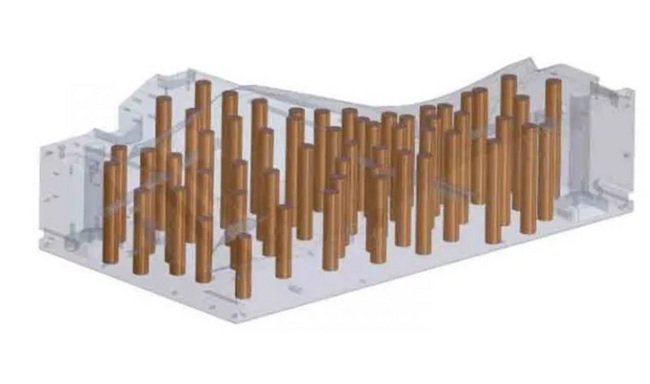

Isobar® Heat Pipes Transfer Large Amounts of Energy at High SpeedsThe Isobar® Heat Pipe achieves thermal conductivity by incorporating a sophisticated solid-state passive pump inside a contained copper unit. This pump takes the form of a fine metallic wick placed tight to the inner wall of a sealed Isobar.In an Isobar® a small quantity of working fluid is placed in an evacuated tube. Heat is applied to the base of the tube, causing the temperature of the working fluid to rise - as this fluid heats, it vaporizes. This vapor then migrates to the colder end of the tube where it condenses and is absorbed by the wick. This wick, through its capillary action, returns the working fluid to the evaporator section, regardless of orientation.Works in Both Heating & Cooling ApplicationsIsobar® technology works equally well with process tooling drawing their energy from heated platens and with integrally heated molds. Energy sources such as oil, steam, or electric heaters may be used. Since the latent heat transfer of evaporation is large, considerable quantities of energy can be transferred and significantly increase the thermal recovery rate under isothermal conditions.Commonly used Isobars are: straight, baffled, finned, and stepped. For these types of Isobars, temperatures can range from 50ºF to 500ºF. Acrolab also engineers low-temperature Isobars that operate at temperatures from -103ºF to 50ºF. These special Isobars are application dependent and are available upon request.Think Outside the BoxAcrolab application engineers have a vast knowledge of thermal dynamics and design and integration.We will consider maintenance, value-add, design, integration, performance, feasibility, and timing for client solutions.Our "outside the box" style of thinking allows Acrolab to deliver unique and even multiple solutions for client requirements.Acrolab Isobars are a 3 in 1 solution. They can provide cooling, heating and/or thermal uniformity management in your application.Acrolab has constructed heat pipes from a variety of materials such as; copper, monel®, stainless steel, inconel® and some additive powder alloys. Copper is most common for what we consider as 'standard applications'. However, choosing a containment material ultimately depends on the working fluid.Since the Isobar® Heat Transfer System resides entirely within the mold there is no need to change your existing mold control system. Acrolab can provide all the components, engineering services, and field installation necessary to construct a complete Isobar® Heat Transfer System. All engineering drawings, electrical schematics, heating elements, Isobar® Heat Pipes, thermocouples, wiring, terminal boxes, electrical connectors, control cables, and a certified installer are provided.Near-Isothermal ConditionsAcrolab's Isobar® Heat Transfer system delivers near-isothermal conditions to all mold surfaces. Our custom-engineered Heat Transfer System uses the Isobar® Heat Pipe in order to provide thermal uniformity to molding applications.Used in Core Pin TechnologyAcrolab's Heat Transfer System is used in core pin technology for thermoset and rubber injection molders; cold runner molds; thermal plastic molding and any application where thermal uniformity is critical.Headlight Housing SpecifiedAcrolab's Isobar® Heat Transfer Systems are specified by over 90% of the headlight housing manufacturers in North America and have been installed in hundreds of injection thermoset headlamp housing molds.Acrolab Isobar® Heat Pipes Transfer Heat Efficiently & EvenlyHeat transfer is achieved by the Wick Structure and Working Fluid inside the Isobar Heat Pipe. The inner surface of the Heat Pipe is lined with the 'wick' that provides the capillary action for liquid moving from the condenser to evaporator, inside the vacuum Isobar Heat Pipe structure. Given that the liquid will, under a vacuum, accept heat well below the boiling point in atmospheric pressure, it will be effective at transferring latent heat at low temperatures.Working Fluids for Isobar Heat PipesSelecting the working liquid for a heat pipe depends on the application temperature range, but water is the most common liquid for a temperature range of 1ºC to 325ºC. When dealing with low temperatures, ammonia and methanol are commonly used. Whereas potassium and sodium are often utilized for high temperature applications. Best to consult with the Acrolab professionals for these types of unique Isobar Heat Pipe applications.Wick Structures for Isobar® Heat PipesHere capillary action is defendant on the structure of the Isobar Heat Pipe wick and the liquid moves from the evaporator section back to the condenser. Acrolab manufactures a full variety of wick structures, depending on the exact application.

Specifications Angle

Specify

Specifications Application

Composite | Other | Plastic | Rubber

Specifications Certifications

International Organization for Standardization (ISO 9001: 2015)

Specifications Orientation In Working Position

Horizontal | Vertical

Specifications Thermal Requirement

Cooling | Heating | Thermal Uniformity