Advanced Digital Humidity Sensor with SCORPION® 2 Technology

Advanced Digital Humidity Sensor with SCORPION® 2 Technology

SKU:DIG-a9476d

Enhance product quality and optimize processes with our Advanced Digital Humidity Sensor with SCORPION® 2 Technology.

Regular price

$599.99

Regular price

Sale price

$599.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Advanced Digital Humidity Sensor with SCORPION® 2 Technology is a cutting-edge solution designed to precisely measure and monitor moisture levels in thermal environments. Ideal for ovens, proofers, dryers, and cooling tunnels, this sensor features dual sensor elements, digital capacitive humidity chips, and Type T thermocouples. With full-scale accuracy for humidity and dew point, rapid response time, and a wide operating temperature range, this sensor ensures product quality by preventing issues like cracking, blistering, and case hardening. The SCORPION® 2 Data Logging Measurement System aids in quality assurance, product consistency, equipment maintenance, food safety optimization, and new product development.

Product Specifications

Additional Information

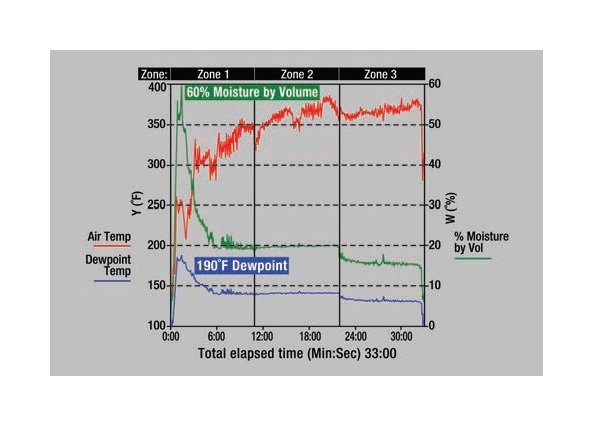

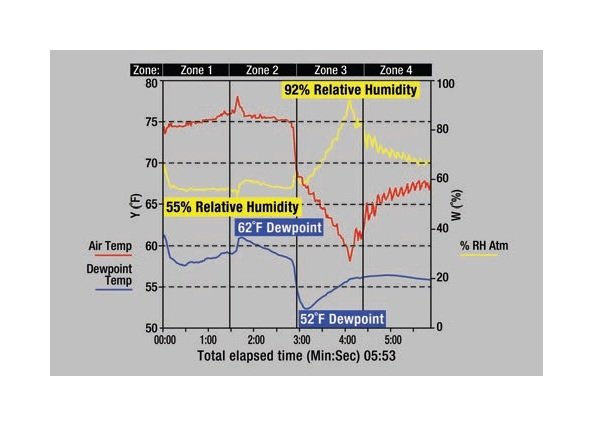

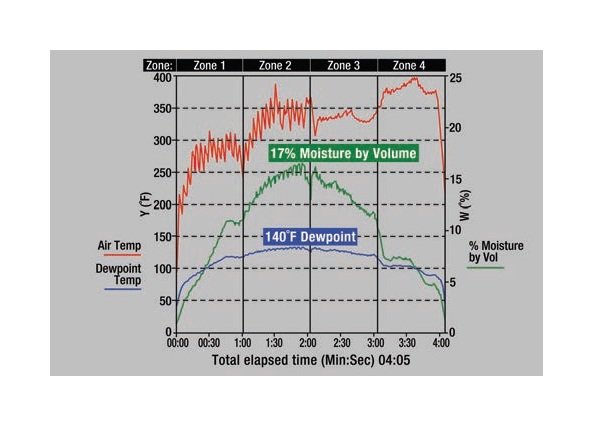

The lack of humidity in a cookie oven can cause case hardening preventing internal moisture from escaping leading to checking (the spontaneous cracking of the cookie after baking).High humidity in bread ovens produces the desirable glossy crust seen on many bread products. For this reason steam injection is often used.High humidity will assist with the killing of pathogens, like salmonella, potentially found in surface toppings.Product throughput lb/hr (kg/hr) can also be affected by when and how much moisture builds in a process. Moisture laden environments reduce baking efficiency, thereby reducing product throughput.The ProcessThe SCORPION® 2 Digital Humidity Sensor is designed to measure the moisture content, of the thermal environment, in both heating and cooling processes. It is applicable to proofers, ovens, dryers and cooling tunnels.Mechanically the Digital Humidity Sensor is comprised of an Air Temperature sensor, two inputs for Product Core Temperature Measurement and a proprietary humidity sampling system to measure Dew Point Temperature, Absolute Humidity and Relative Humidity. The sampling system contains patent pending Anti-Saturation Technology™ allowing measurements in very high dew point environments such as steam injection.The Digital Humidity Sensor is engineered to be compatible with direct gas fired (DGF) ovens. Unlike oxygen sensor technology, which can be off by as much as 25% due to combustion gases in DGF ovens, the accuracy of the digital humidity sensor remains the same regardless of the oven platform.The Humidity Sensor travels through the process with the product, yielding a precise profile of moisture experienced by the product.Analyzing the ResultsIn high temperature applications above 212ºF (100ºC), absolute humidity is displayed. The user can choose between % Moisture by Volume or Humidity Mass Ratio (lb water/lb dry air or kg water/kg dry air).In low temperature applications below 212ºF (100ºC), % Relative Humidity is displayed.In both high and low temperature applications, the dew point temperature and dry bulb air temperature is displayed.Humidity in ovens is generally controlled by extraction fans and dampers. Here the sensor is used to display the shape of the humidity profile as well as the peak moisture value obtained and where. In proofers it is used to document the temperature and relative humidity of the proof cycle. In cooling tunnels it is used to monitor dew point temperature, preventing condensation on the product surface which causes blooming.

Applications

Quality AssuranceRecord your processing conditions when your product quality is within specification. Save these profiles for future reference as "target" conditions. Use the SPC function included in the software to establish upper and lower control limits for your process temperature, air velocity, heat flux and humidity profiles.Line Start-upTake a SCORPION® 2 profile a few minutes before introducing product into a process. This is a good check that the process has reached the correct operating conditions before production is started.Product Consistency Line-to-LineCompare SCORPION® 2 profiles for two process ovens, perhaps in different factories, that are supposed to be making the same product.Commissioning and MaintenanceHeat process ovens usually include dampers and other controls that must be set by the installation engineer. Use SCORPION® 2 to check that these have been set correctly. Repeat the profiles as part of your preventative maintenance program to detect drift in zone conditions and to pin-point the cause of problems when they do occur.Analyze Equipment PerformanceMost oven manufacturers now use SCORPION® 2 to design their heat processes. This is an invaluable tool for design engineers to balance heat and airflow across the width and along the length of the process oven.Optimize Food Safety and ThroughputControlling internal food temperature is key to achieving food safety. Today's food processors must also document how they are meeting food safety requirements with data. The SCORPION® 2 Data Logging Measurement System makes both jobs easier.The SCORPION® 2 Data Logger with R&D Smart Sensor and Product Probes simplifies the measurement of environment temperature, airflow, energy transfer and internal product core temperature. Plus the SCORPION® 2 Software (SV8) calculates and displays the % kill for a specified pathogen reduction level.By combining this ease of measurement with robust data capture, the SCORPION® 2 System enables better process optimization. No other system makes achieving desired levels of food safety and throughput so simple.New Product DevelopmentUse SCORPION® 2 to record the processing conditions you develop in the lab or in a pilot plant. Then use SCORPION® 2 again to establish the same conditions as the new product is transferred to a full-scale production line.

Features

Data available for displayAir temperature (ºF or ºC)Dew point temperature (ºF or ºC)% Moisture by volumeHumidity mass ratio (lb water/lb dry air or kg water/kg dry air)% Relative humidity atmosphere

Technical Summary Absolute Humidity Range Moisture By Volume

0 to 100 %

Technical Summary Battery Running Time

4+ hour

Technical Summary Dew Point Range

0 to 100 ºC | 32 to 212 ºF

Technical Summary Full Scale Accuracy For Humidity And Dew Point

5 %

Technical Summary Number Of Product Probe Inputs

2

Technical Summary Number Of Sensor Elements

2

Technical Summary Operating Temperature Range

0 to 350 ºC | 32 to 662 ºF

Technical Summary Relative Humidity Range Rh Atm

0 to 100 %

Technical Summary Response Time T60 In Air At 1 Meter Per Second

3 second

Technical Summary Sensor Type

Digital Capacitive Humidity Chip | Type T Thermocouples