Advanced Heat Flux Sensor System

Advanced Heat Flux Sensor System

SKU:HEA-52dd26

Enhance product quality control with our Advanced Heat Flux Sensor System. Monitor convective and radiant heat fluxes for optimized outputs in thermal applications.

Regular price

$2,799.99

Regular price

Sale price

$2,799.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Advanced Heat Flux Sensor System offers precise monitoring of convective and radiant heat fluxes, facilitating optimal product quality control. With Type T Thermocouples and a wide operating temperature range (-50 to 350 ºC), it ensures accurate data collection for quality assurance and equipment optimization across a variety of thermal applications. Ideal for line start-ups, equipment maintenance, and food safety compliance, this system enhances operational efficiency and product consistency.

Product Specifications

Additional Information

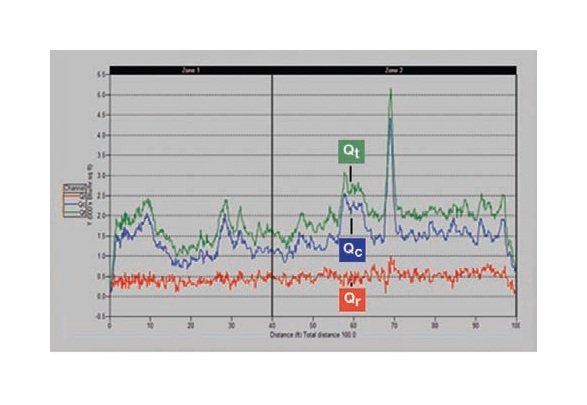

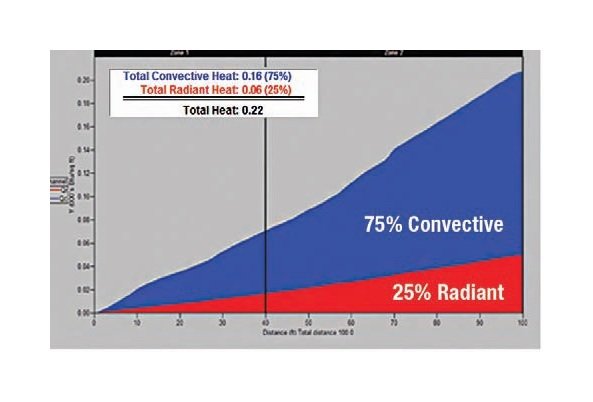

When the heat flux component profiles are matched, the two lines will produce the same product.The ProcessThe SCORPION® 2 Heat Flux Sensor is designed to measure convective and radiant heat fluxes at product level, and display the results in Btu/hr·ft² or W/m². Convective and radiant heat is absorbed by the band, which serves as the conduction mechanism to the product. The sensor travels through the process with the product, and the oven under full load, yielding a precise profile of heat flux components experienced by the product. Mechanically the sensor is comprised of two copper spades and a bulk air temperature sensor. The black spade provides a measurement summation of convective and radiant heat fluxes, and the gold spade provides a measurement of only the convective heat flux component. The gold plated temperature sensor provides a measurement of the free stream air temperature associated with convection.Analyzing the ResultsThe Heat Flux Sensor measures the flow of energy experienced by the product, from above the conveyor, and identifies which modes of heat transfer are predominant. Raw data from the heat flux sensor consists of several temperature measurements at precise locations in the sensor assembly. A mathematical model, representative of the physical measurement system, is applied to the measured values via the SCORPION® 2 software. The resultant heat flux components Qradiant, Qconvective and Qtotal are displayed in a 2D Line Graph against time, distance, or % travel through the process. An interesting note is the large convective spike seen in zone 2 of this oven profile, which was traced to a separation in an air supply plenum.Critical to understanding finished product characteristics is knowing the total heat experienced by the product, and the component quantities of radiant and convective heat fluxes. This is best viewed in the Total Heat Graph displaying the radiant and convective components as Joules/m² (Btu/ft²). The difference in proportions of heat types explains why one oven bakes differently than another – and analyzing and controlling these differences is fundamental to product quality.

Applications

Quality AssuranceRecord your processing conditions when your product quality is within specification. Save these profiles for future reference as "target" conditions. Use the SPC function included in the software to establish upper and lower control limits for your process temperature, air velocity, heat flux and humidity profiles.Line Start-upTake a SCORPION® 2 profile a few minutes before introducing product into a process. This is a good check that the process has reached the correct operating conditions before production is started.Product Consistency Line-to-LineCompare SCORPION® 2 profiles for two process ovens, perhaps in different factories, that are supposed to be making the same product.Commissioning and MaintenanceHeat process ovens usually include dampers and other controls that must be set by the installation engineer. Use SCORPION® 2 to check that these have been set correctly. Repeat the profiles as part of your preventative maintenance program to detect drift in zone conditions and to pin-point the cause of problems when they do occur.Analyze Equipment PerformanceMost oven manufacturers now use SCORPION® 2 to design their heat processes. This is an invaluable tool for design engineers to balance heat and airflow across the width and along the length of the process oven.Optimize Food Safety and ThroughputControlling internal food temperature is key to achieving food safety. Today's food processors must also document how they are meeting food safety requirements with data. The SCORPION® 2 Data Logging Measurement System makes both jobs easier.The SCORPION® 2 Data Logger with R&D Smart Sensor and Product Probes simplifies the measurement of environment temperature, airflow, energy transfer and internal product core temperature. Plus the SCORPION® 2 Software (SV8) calculates and displays the % kill for a specified pathogen reduction level.By combining this ease of measurement with robust data capture, the SCORPION® 2 System enables better process optimization. No other system makes achieving desired levels of food safety and throughput so simple.New Product DevelopmentUse SCORPION® 2 to record the processing conditions you develop in the lab or in a pilot plant. Then use SCORPION® 2 again to establish the same conditions as the new product is transferred to a full-scale production line.

Technical Summary Battery Running Time

50+ hour

Technical Summary Channels

-Convection Heat Flux: Qc (Btu/hr ft² or kW/m²) | -Convective Air Temperature Tc (ºF or ºC) | -Convective Heat Transfer Coefficient: Hc (Btu/hr ft² ºF or kW/m² ºC) | -Perceived Radiation Temperature: Tr (ºF or ºC) | -Radiation Heat Flux: Qr (Btu/hr ft² or kW/m²) | -Total Convective and Radiant Heat (Btu/ft² or kJ/m²) | -Total Heat Flux: Qt = Qr + Qc (Btu/hr ft² or kW/m²)

Technical Summary Full Scale Accuracy

5 %

Technical Summary Number Of Channels Displayed

8

Technical Summary Number Of Sensor Elements

3

Technical Summary Operating Temperature Range

-50 to 350 ºC | -58 to 662 ºF

Technical Summary Sensor Type

Type T Thermocouples