Advanced Rising Film Tubular Evaporator

Advanced Rising Film Tubular Evaporator

SKU:EVA-298808

Efficiently process viscous products with the Advanced Rising Film Tubular Evaporator for compact, cost-effective solutions in various industries.

Regular price

$4,999.99

Regular price

Sale price

$4,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

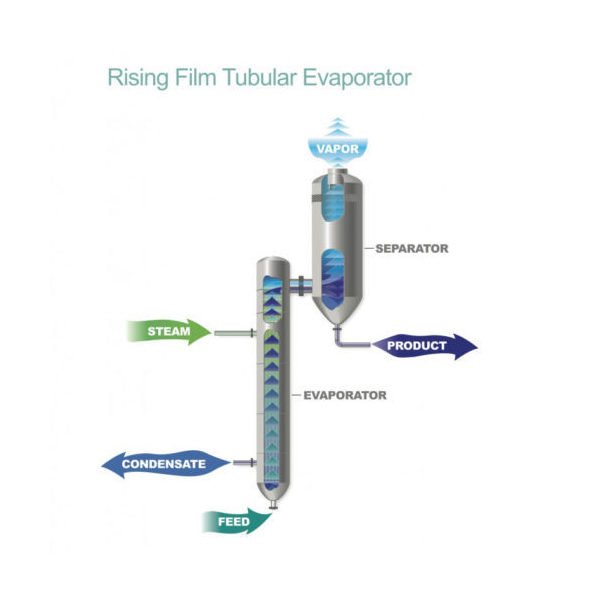

The Advanced Rising Film Tubular Evaporator, also known as the Vertical Rising Film Concentrator (VRC), utilizes natural circulation thermo-siphon action to efficiently process viscous products. It features a compact design with high heat transfer coefficients, reducing capital costs. Ideal for a range of industries including Agricultural Chemical Production, Food and Beverage, and Pharmaceutical Production, this system offers simple operation and eliminates the need for large pumping systems. Its components include a Condenser, Heat Recovery Exchangers, and a Vapor/Liquid Separator.

Product Specifications

Applications Applications

Brewery Waste Concentration Systems | Cannabinoid Oil Refining | Chemical Plant Waste Systems | Chemical Recovery In Metal Plating processes | Concentration Of Sugar Solutions | Evaporative Crystallizers For Salts | Gelatin Production | Pharmaceutical Product Recovery From Waste Streams | Phosphoric Acid Production | Removal Of Solvents From Oils | Sodium Hydroxide (NaOH) Production | Sulfuric Acid Production

Components Components

Condenser | Heat Recovery Exchangers | Main Evaporator Heater | Vacuum System | Vapor/Liquid Separator

Industries Industries

Agricultural Chemical Production | Chemical Production | Food and Beverage | Fuel Ethanol | Oil and Gas | Pharmaceutical Production | Pulp and Paper

Key Benefits Key Benefits

Simple to operateEliminates large circulation pumpsCompact configurationsHigh heat transfer coefficients reduce capital costNot generally suitable for more than four (4) effects due to higher temperature differences needed