Alloy Steel Shoulder Screw with Nylon Pellet - 5/16-18 x 1/2

Alloy Steel Shoulder Screw with Nylon Pellet - 5/16-18 x 1/2

SKU:VER-5145c6

Premium Alloy Steel Shoulder Screw with Nylon Pellet - Ensures secure, reliable fastening for diverse applications.

Regular price

$12.99

Regular price

Sale price

$12.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Enhance your fastening needs with our Alloy Steel Shoulder Screw featuring a Nylon Pellet for enhanced grip and durability. This screw, with a 5/16-18 thread size, 1/2-inch length, and plain finish, ensures secure installations. Compliant with federal procurement standards, it meets industry-specific certifications, delivering reliability and precision in every application.

Product Specifications

Additional Information Additional Information

Protection device C 600 according ISO 21940-23Measuring unit CAB 820, optional CAB 920

Design Design

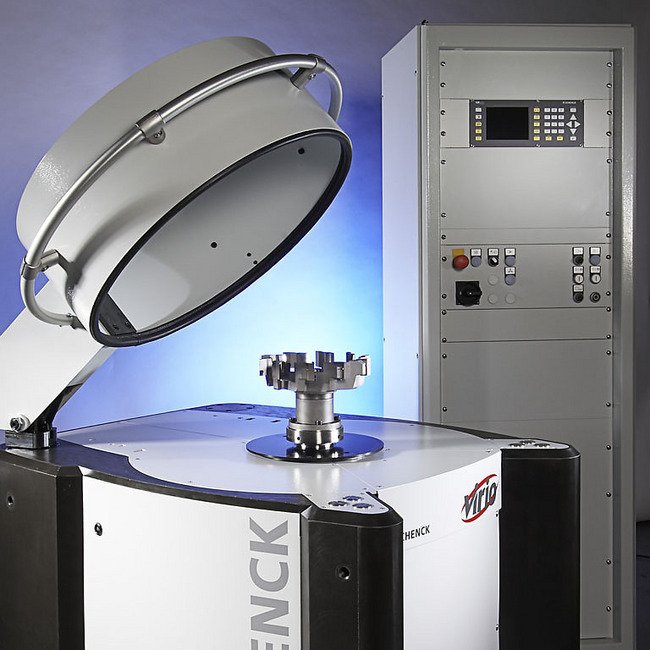

Hard-bearing, vertical balancing machine in molded mineral design.Measuring unit with permanent calibration and digital signal processing.Measuring unit CAB 820 with colored, graphics capable LCD-Display. Cache memory for 99 rotor data and extensive basic configuration for the  different correction methods.Optional: CAB 920 with Windows operating system, TFT color display with touchscreen function and vector view of the unbalance. Designed as network compatible embedded PC with memory card and permanent storage of the measured unbalance values. Simplest  menu navigation in "Easy Mode".The workplace exists essentially of the following components: control cabinet with measuring unit and machine with protection and operating elements

Features Features

The machine is usable without foundation, but with screw connectionShort rebuilding times, cause of the hard-bearing principleHigh balancing accuracyErgonomic designContinuously variable drive unitsselectable automatic operating sequence with adjustable acceleration and braking times.Extendable with integrated drilling unit

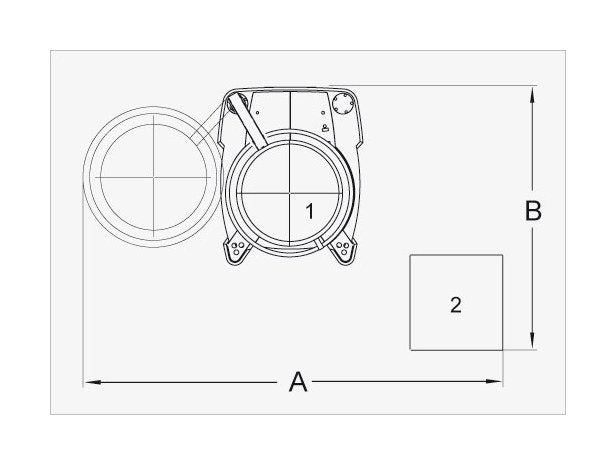

Machine Machine Depth B

850 mm

Machine Machine Height C

1200 mm

Machine Machine Width A

850 mm

Machine Note For Machine Dimensions

Data non-binding, dependent on the respective equipment supplied

Options Options

Report Printer

Options Report Printer Bestell Number

R0060105.01

Power Supply Alternating Current Ac Voltage

400 V

Power Supply Frequency

50 Hz

Power Supply Number Of Phase

3

Power Supply Voltage Tolerance

+6 % | -10 %

Range Of Application Range Of Application

Vertical balancing machines of the type VIRIO10 - VIRIO300 for 1 or 2 planes, are well dedicated for all workpieces without own shafts, like pressure plates, brake discs, brake drums, flanges, housings, clutch parts, blowers, knives, impellers, pulleys, saws, grinding discs, flywheels, dampers, turbo charger a.s.o. They are applied in the make-to-order-production and for small series productions. The machines are rated for an upright operation and usable on variously stations.The rebuilding to different rotor types is practicable within shortest time by changing the adapters. Available are 4 different drive units: 1.5 kW, 2.2 kW, 4.0 kW, or a servo drive for automatic indexing. For the indication of unbalance we provided the polar display, regular or irregular components with integration of forbidden zones. We also provided a milling software for the external correction. The correction data can be sent to the external milling machine via ASCII - interface (CAB 700), or directly (CAB 920).The correction of unbalance can be done directly on the machine by adding weight or by reducing weight, using an integrated drilling unit. The indication of the mass of unbalance to be reduced will be announced by the numbers, angle and depth of holes to be drilled. During the correction a stylized drill shows the proceed.Optional deliverable are correction units for welding, riveting and grinding.

Rotor Maximum Rotor Diameter

610 mm

Rotor Maximum Rotor Height

250 mm

Rotor Maximum Rotor Weight

10 kg

Rotor Spindle Diameter

80 mm

Rotor Spindle Type

H7

Technical Data Accuracy 2 Planes

2 to 4 | 18 to 25

Technical Data Balancing Speed

120 to 1200 min-1

Technical Data Basic Machine Options

Balancing in two planes | Mass correction system - On Request | Measuring instrument CAB 920 | Pneumatic spindle lock device | Pneumatic unclamping system | Protective device to ISO 21940-23 (International Organization of Standardization) | Software Options - On Request

Technical Data Brands

SCHENCK

Technical Data Frequency Squirrel Drive

1.5 kW

Technical Data Measuring Unit

CAB 820

Technical Data Servo Drive

8 N·m

Technical Data Sound Pressure Level With Class C Protection Lpa

60 to 70 dBA