Alloy Steel Socket Head Shoulder Screw with Nylon Pellet - 1/2-13 x 3/4 - Plain Finish

Alloy Steel Socket Head Shoulder Screw with Nylon Pellet - 1/2-13 x 3/4 - Plain Finish

SKU:STA-f821be

Enhance your fastening with our durable Alloy Steel Socket Head Shoulder Screw. Ideal for heavy-duty applications, this screw ensures secure and long-lasting connections.

Regular price

$12.99

Regular price

Sale price

$12.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Upgrade your fastening solutions with our Alloy Steel Socket Head Shoulder Screw featuring a Nylon Pellet. This high-quality screw boasts a thread size of 1/2-13, a length of 3/4 inches, and a sturdy plain finish. Its reliable performance, precise engineering, and durability make it ideal for heavy-duty applications in various industries. Designed to meet strict standards, this screw ensures secure and long-lasting connections.

Product Specifications

Machine Depth B

390 mm

Machine Height C

120 mm

Machine Note For Dimensions

Data non-binding, depending on respective equipment 44

Machine Width A

480 mm

Power Supply Frequency

50 Hz

Power Supply Voltage

230 V

Range Of Application Range Of Application

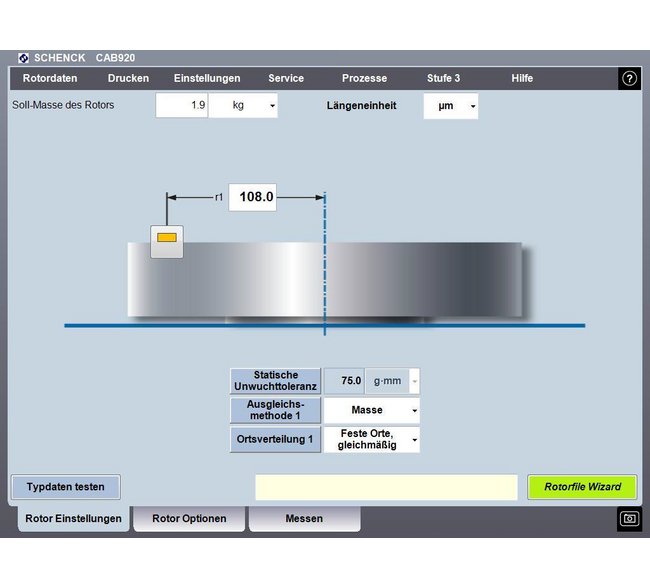

Measurement of the static unbalance of disc-shaped rotors such as unfired grinding discs, propellers and ventilators.Unbalance correction by addition of material directly on the machine or by removal of material on separate correction units.Can be used for mere unbalance measurement, for tasks in production involving unbalance correction, for incoming goods inspection, for re-balancing and for weight measurement.

Special Features Special Features

Direct display on achieving of tolerance limit, operator prompting during calibration process, memory for calibration data for easy change-over from one work-piece type to the next at the push of a button.Compact design ensures optimum ease of deployment.Program for compensating of adapter errors, test program displaying operator or system errors, process control through host computer is possible, integral product data base.

Technical Data Available Versions

Enclosure-Mounted Version for Large Rotors | Table-Top Version

Technical Data Basic Machine Order Number

R0050500.02

Technical Data Brands

SCHENCK

Technical Data Diameter

1000 mm

Technical Data Load Carrying Capability Of The Balancing Unit

20 to 60 kg

Technical Data Maximum Measurable Unbalance

100 kg/mm

Technical Data Measuring Time

2 to 5 seconds

Technical Data Measuring Uncertainty

40 g/mm

Technical Data Rotor Applications

Complete wheels | Grinding discs | Propellers | Vehicle tires | Ventilators, fans