Alloy Steel Socket Head Shoulder Screw with Nylon Pellet - 2 1/4, Plain Finish

Alloy Steel Socket Head Shoulder Screw with Nylon Pellet - 2 1/4, Plain Finish

SKU:HOR-021bbc

Premium Alloy Steel Socket Head Shoulder Screw for lasting stability and secure fastening.

Regular price

$9.99

Regular price

Sale price

$9.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Upgrade your fastening solutions with our Alloy Steel Socket Head Shoulder Screw featuring a Nylon Pellet for enhanced stability. This 2 1/4 inch screw offers exceptional durability and strength while ensuring a secure fit. The Plain finish adds a sleek touch, making it ideal for diverse applications in machinery, automotive, and more. Compliant with strict procurement standards, this screw guarantees reliability and performance.

Product Specifications

Design Design

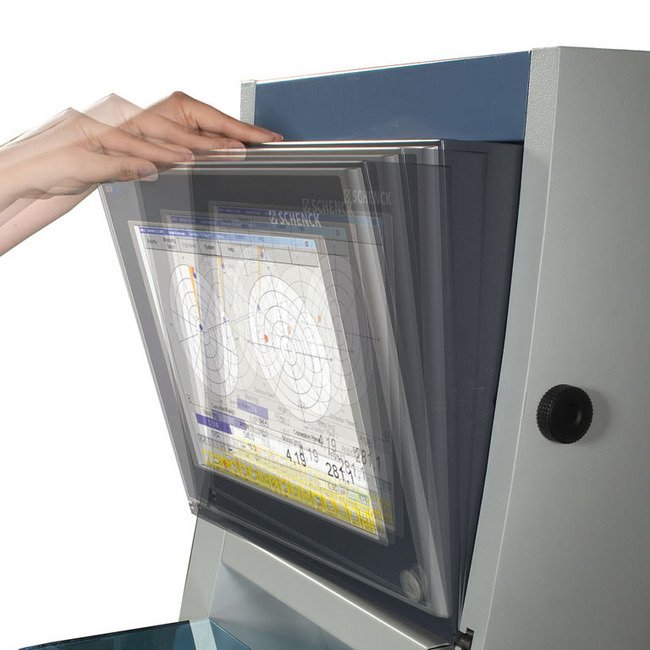

Hard-bearing, horizontal balancing machine with permanent calibration for standing or seated operatorThe complete workplace consists of the following major components: machine table, mechanical balancing unit comprising roller bearings or V-blocks, belt drive, measuring instrument and control systemThe machine can be installed without foundations and without bolts and is immediately ready for operationMeasuring CAB 820 (basic measuring unit)Optional: Measuring device CAB 920 - the high end solution regarding operation, versatility and accuracy

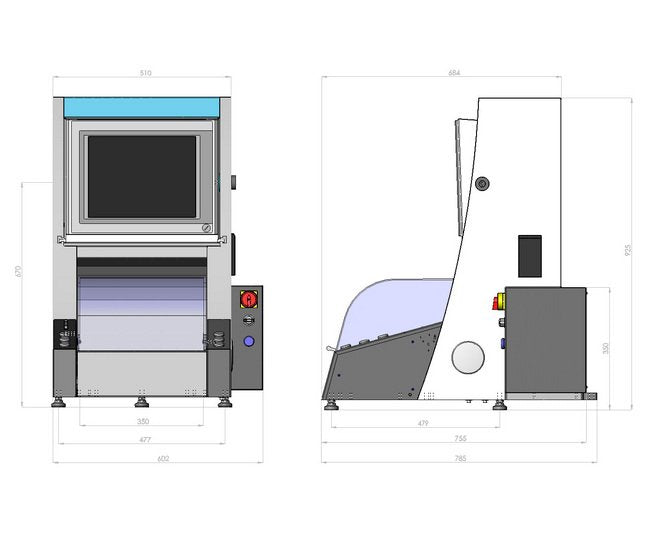

Machine Machine Depth

785 mm

Machine Machine Height

925 mm

Machine Machine Width

602 mm

Options Options

Color Printer for Report Print-Outs | External Interfaces for Printers and Network (CAB 920) | Graduation Scanning as Reference and Angle Position Sensor | Protection in Accordance with ISO 7475 Class C (Protection against Parts Flying Off) | Test Rotor (500 g) with Test Weights

Power Supply Alternating Current Ac Voltage

230 V

Power Supply Frequency

50 Hz

Range Of Application Range Of Application

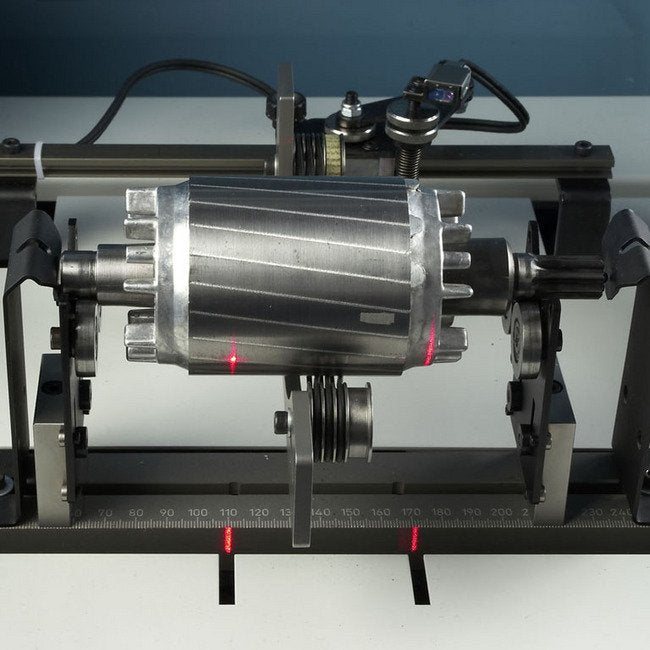

Universal balancing machine Pasio 5 is ideally suited to extremely small work-pieces such as miniature armatures, miniature fans and complete assemblies. They are conceived for use in research and development, in batch production or in repair shops.Change-over to new rotor types is straightforward and only requires a minimum of time.Unbalance correction is made manually by addition of material (e.g. balancing plasticine) directly on the machine or by removal of material on optional manually operated or semi-automated machining units.

Rotor Journal Diameter

2 to 22 mm

Rotor Maximum Journal Distance

240 mm

Rotor Maximum Rotor Diameter

150 mm

Rotor Maximum Rotor Weight

1 kg

Special Features Special Features

Ergonomic operator conceptQuick change-over from workpiece to the nextSuitable for magnetized rotorsSpace-saving single-unit design with integral measuring station and measuring unitEasy to operate through permanent calibration - requires no calibration runsCorrection in two planes or separate according to static and couple unbalance is possibleRotors can be mounted on their original shafts or on mounting arbors, complete assemblies can be installed in their housingAutomatic measuring cycle with infinitely variable settings for acceleration, measuring and braking time.

Technical Data 3 Color Painting

RAL 5014 (Blue-Gray) | RAL 7024 (Graphite Gray) | RAL 7035 (Light Gray)

Technical Data Automatic Angle Indexing

Included

Technical Data Belt Drive

Tangential with O-rings from Bottom

Technical Data Brands

SCHENCK

Technical Data Drive Power

100 W

Technical Data Maximum Sensitivity Cab 820

0.2 g/mm

Technical Data Maximum Sensitivity Cab 920

0.1 g/mm

Technical Data Measuring Devices

CAB 802 | CAB 920 with Touch Screen Operation

Technical Data Minimum Achievable Residual Unbalance Per Plane

0.1 gmm/kg

Technical Data Sound Pressure Level With Class C Protection Lpa

< 60 dBA

Technical Data Total Weight

135 kg

Technical Data Type

V-Blocks