Alloy Steel Socket Head Shoulder Screw with Nylon Pellet, 3/8-16 x 1 1/2, Plain Finish

Alloy Steel Socket Head Shoulder Screw with Nylon Pellet, 3/8-16 x 1 1/2, Plain Finish

SKU:VER-0f2461

Premium Alloy Steel Socket Head Shoulder Screw with Nylon Pellet for secure and precise fastening. Compliant with Federal/DoD procurement standards.

Regular price

$6.99

Regular price

Sale price

$6.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Upgrade your fastening solutions with our Alloy Steel Socket Head Shoulder Screw featuring a Nylon Pellet. This 3/8-16 threaded screw, 1 1/2 inches long with a durable Plain finish, ensures secure and precise fastening. Crafted from high-quality alloy steel, it offers exceptional strength and longevity. Ideal for industrial applications requiring reliability and performance. Compliant with Federal/DoD procurement standards and suitable for GSA requirements.

Product Specifications

Design Design

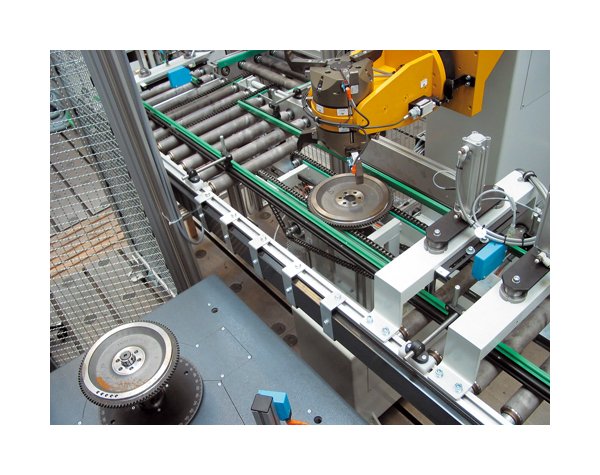

Fully automatic single-station machine with integrated high-performance drill unit. Freely programmable control with fault diagnosis and status display. Clamping of the work-piece to the balancing machine by precision adapters with pneumatic unclamping mechanism. Support device located under the work-piece during drilling, to compensate for the drill force. Unbalance evaluation, correction calculation and correction control through PC controlled measuring unit. Manual loading or optional loading for the machine by a hand-operated system and the corresponding conveying technique.

Machine Machine Height C

2200 mm

Machine Machine Length A

1500 mm

Machine Machine Width B

1700 mm

Machine Note For Machine Dimensions

Data non-binding, dependent on the respective equipment supplied

Options Drill Swarf Extractor Order Number

R0030102.01

Options Options

Drill Swarf Extractor

Range Of Application Range Of Application

Measurement and correction of single-plane unbalance in disc shaped rotors with and without shafts, such as flywheels, TMF (twin mass flywheels), brake-drums, gears, clutch-plates, compensation shafts, blowers, etc.Flexible integration into production line and simple change over of the machine to different rotor types by exchange of work-piece interface adapter and selection of rotor type file.Unbalance correction by axial or radial drilling in polar or component format. If the initial unbalance is larger than can be corrected by one drilling action, multiple holes can be drilled.Other unbalance correction methods such as milling, welding, riveting or punching can be integrated into the machine on request. The correction units are flexible and are adapted to the work-piece.

Rotor Maximum Rotor Diameter

240 to 600 mm

Rotor Maximum Rotor Height

10 to 200 mm

Rotor Maximum Rotor Weight

5 to 100 kg

Technical Data Air Pressure

500 kPa

Technical Data Balancing Speed

800 min-1

Technical Data Basic Machine Order Number

R0030200.01

Technical Data Benefits

Analog depth control | Manual change-over | Numerical depth control | Unbalance correction by drilling, horizontal

Technical Data Brands

SCHENCK

Technical Data Cycle Time

30 seconds

Technical Data Drilling Performance St 60

8 to 28 mm

Technical Data Measuring Uncertainty

2 to 20 g/mm

Technical Data Measuring Unit

CAB 950

Technical Data Power Consumption

12 kV·A

Technical Data Required Air Flow

0.5 m³/h