Alloy Steel Socket Head Shoulder Screw with Nylon Pellet Insert - 1/2-13 x 1 - Plain Finish

Alloy Steel Socket Head Shoulder Screw with Nylon Pellet Insert - 1/2-13 x 1 - Plain Finish

SKU:HOR-46acd5

Enhance fastening with our Alloy Steel Socket Head Shoulder Screw featuring Nylon Pellet insert for secure, vibration-resistant joints.

Regular price

$5.99

Regular price

Sale price

$5.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Upgrade your fastening solutions with our Alloy Steel Socket Head Shoulder Screw featuring a Nylon Pellet insert for enhanced grip and vibration resistance. With precise 1/2-13 thread size and 1-inch length, this screw offers secure and durable joint connections. The Plain finish ensures a professional look, while the alloy steel construction guarantees strength and corrosion resistance. Ideal for industrial, commercial, and institutional applications, this screw meets stringent procurement standards, making it a reliable choice for your projects.

Product Specifications

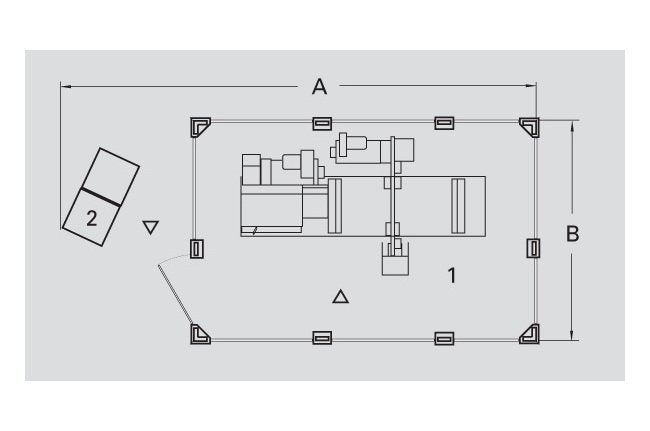

Machine Machine Depth B

1650 mm

Machine Machine Height C

2000 mm

Machine Machine Width A

2250 mm

Machine Note For Machine Dimensions

Data non-binding, dependent on the respective equipment supplied

Options Measuring Unit Cab 920 Order Number

R0060401.01

Options Options

Angular Roller Bearings | End Drive (Other data upon request) | Mass Correction System - On Request | Measuring Unit (CAB 920) | Overslung Belt Drive (BK) | Protective Device as Per ISO 7475 (Up to HM 10 with Protection Class C, in all other Cases Protection Class B) | Report Printer | Software Options - On Request | Underslung Belt Drive (BU) | Various Roller Carriage - On Request

Options Report Printer Order Number

R0060405.01

Power Supply Alternating Current Ac Voltage

400 V

Power Supply Alternating Current Ac Voltage Tolerance

+6 % | -10 %

Power Supply Frequency

500 Hz

Power Supply Number Of Phase

3

Range Of Application Range Of Application

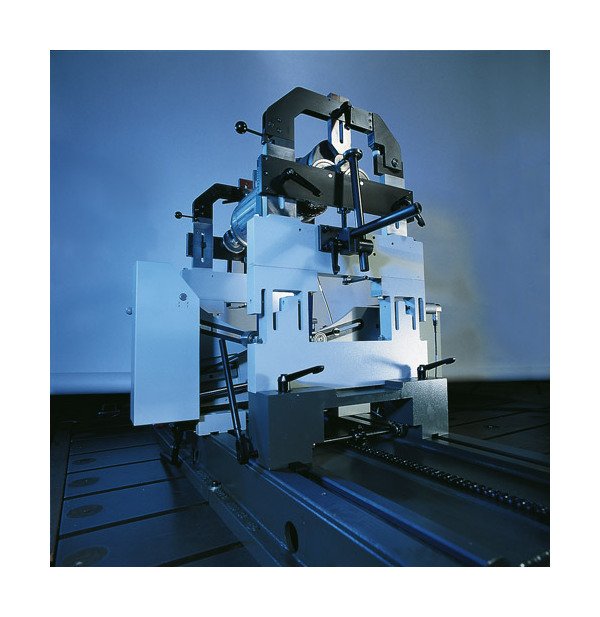

Universal balancing machines series HM enable precise balancing of a wide spectrum of rotors. They are suitable for cylindrical rotors having their own shaft journals and for balancing disc shaped rotors on balancing arbors.Permanent calibration, ergonomic design and a logical operating sequence facilitate operation.A modular design principle and a wide range of accessories make the machine highly flexible.Schenck universal balancing machines series HM are a highly efficient investment, both for one-off rotors and for small batches.

Rotor Bearing Journal Diameter

9 to 140 mm

Rotor Maximum Bearing Distance

1330 mm

Rotor Maximum Rotor Diameter

1260 mm

Rotor Maximum Rotor Weight

100 kg

Sequence Of Operations Sequence Of Operations

Manually load work-piece on the bearing pedestals, close hold-down bearings and connect drive (belt drive or drive shaft).Close protection device and start automatic measuring sequence:Acceleration, determination and display of the unbalance on the measuring instrument, brake. The readout is retained on the measuring instrument even after the measuring run has ended.Open protection device, manually correct unbalance (if required).Check correction result (with measuring instrument displaying whether the tolerance has been achieved) and unload the rotor from the machine.

Special Features Special Features

Easy to operate - hard-bearing principle eliminates the need for calibration runsProvides for correction in two planes or separate according to static and couple unbalanceRotors can be mounted on their original shafts or on mounting arbors, optionally with mounted anti-friction bearingsAngle indexing display in case of belt driveAutomatic measuring cycle with infinitely variable settings for acceleration, measuring and braking timeUpgradeable by many additional modules e.g. for mass correction

Technical Data Basic Machine Order Number

R0060400.02

Technical Data Brands

SCHENCK

Technical Data Drive Power

1.1 kW

Technical Data Measuring Unit

CAB 820

Technical Data Minimum Achievable Residual Unbalance Maru Per Ba

1.6 g/mm

Technical Data Minimum Balancing Speed

120 min-1

Technical Data Sound Pressure Level With Belt Drive Lpa

60 to 70 dBA