Alloy Steel Socket Head Shoulder Screw with Nylon Pellet Insert - 5/8-11 x 1 1/4 - Plain Finish

Alloy Steel Socket Head Shoulder Screw with Nylon Pellet Insert - 5/8-11 x 1 1/4 - Plain Finish

SKU:VER-e47c45

Enhance fastening with our Alloy Steel Socket Head Shoulder Screw - Nylon Pellet Insert - 5/8-11 x 1 1/4 - Plain Finish.

Regular price

$8.99

Regular price

Sale price

$8.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Upgrade your fastening solutions with our Alloy Steel Socket Head Shoulder Screw featuring a durable Nylon Pellet insert. With a Thread Size of 5/8-11 and a Length of 1 1/4 inches, this screw offers reliable strength and precision. The Plain finish adds corrosion resistance, making it ideal for industrial applications. Compliant with Federal/DoD procurement standards, this screw is a secure choice for government projects.

Product Specifications

Additional Information Additional Information

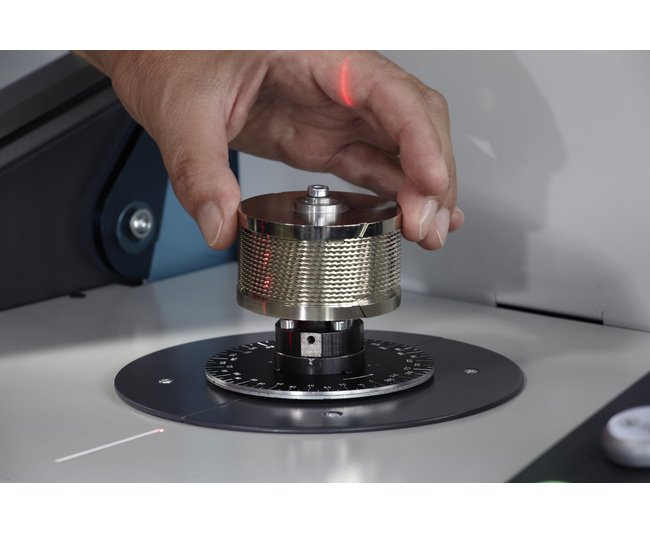

Working PrincipleManually load rotor in the balancing unit, center the work-piece with an interface adapter and close the protective shroudStart the automatic measuring run. Accelerate, measure and display the unbalance on the measuring unit, automatically index to the correction position. The measured value display is retained after each measuring run.Open the protective shroud, unload and, if necessary, correct the unbalance.Check the result of correction (achievement of tolerance is displayed by the measuring unit) and unload the rotor from the balancing unit.CAB 700 is a compact basic instrument for all standard balancing tasks:Simple, menu-driven operation, clear display and high accuracy allow perfect balancing of rotors by less experienced operators.Measuring unit CAB 920 as a high end solution - with regard to operation and versatility, as well as accuracy

Design Design

Force-measuring, vertical balancing machine with permanent calibration and automatic operationDesigned for table-top placement, suitable for a seated operatorBalancing unit, measuring unit and control cabinet are mounted on a common base plate.The dynamometer-mounted precision balancing spindle supports a removable adapter for centering the rotors and is driven by a flange-mounted electric motor.The protective enclosure designed according to ISO 21940-23 is part of the standard equipment.Measuring unit CAB 820 with colored, graphics capable LCD-Display. Cache memory for 99 rotor data and extensive basic configuration for the different correction methods.Optional: CAB 920 with Windows operating system, TFT color display with touchscreen function and vector view of the unbalance. Designed as network compatible embedded PC with memory card and permanent storage of the measured unbalance values. Simplest menu navigation in "Easy Mode".

Machine Machine Depth B

785 mm

Machine Machine Height C

925 mm

Machine Machine Width A

602 mm

Power Supply Frequency

50 Hz

Power Supply Voltage

240 V

Range Of Application Range Of Application

Measurement and correction of unbalance in rotors without their own shaft, in one or two planes. Typical examples of rotors are blank CDs, small blowers without self-propulsion, centrifuges, deflection pulleys, clutch components and rotating paint spray nozzles. A shorter spindle distance and protective shroud provide faster, safer and more accurate balancing.

Rotor Maximum Rotor Diameter

220 mm

Rotor Maximum Rotor Height

150 mm

Rotor Maximum Rotor Weight

0.5 kg

Technical Data Balancing Speed

1000 to 3000 min-1

Technical Data Brands

SCHENCK

Technical Data Drive Power

0.1 kW

Technical Data Measuring Uncertainty

0.05 to 0.075 g/mm

Technical Data Sound Pressure Level With Class C Protection Lpa

< 60 dBA