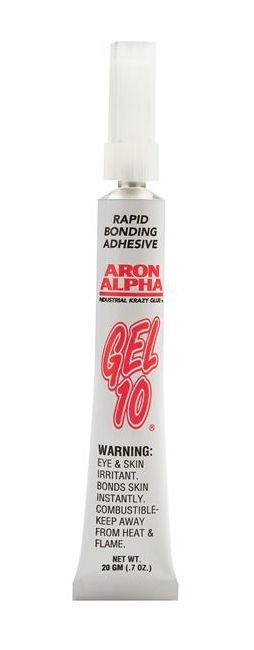

ARON ALPHA Type Gel 10 - Thixotropic Instant Adhesive

ARON ALPHA Type Gel 10 - Thixotropic Instant Adhesive

SKU:INS-cad953

Fast-setting thixotropic instant adhesive with exceptional gap-filling ability for versatile applications.

Regular price

$29.99

Regular price

Sale price

$29.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

ARON ALPHA Type Gel 10 is part of the thixotropic instant adhesive 200TX Series, offering a no-run, no-glue string formulation. Designed for high-speed dispensing and automatic assembly applications, its exceptional gap-fill ability and fast setting times make it ideal for diverse bonding needs. With high cohesion and compatibility with various materials, including metals, plastics, rubber, and more, ARON ALPHA Type Gel 10 ensures reliable and durable bonds. Its clear color, wide temperature range, and good bonding strength cater to a range of industrial and commercial applications.

Product Specifications

After Curing Appearance Solid State

Colorless and Transparent

After Curing Hardness Rockwell M Solid State

85

After Curing Softening Point Vicat Solid State

145 ºC | 293 ºF

Applications 0

For Wood Work: Suitable for bonding wood. Complete and wide range of adhesive grades available. Suitable for assembling wooden products and repairing. Wooden molds and expensive rare woods. Artificial Marble: For use on artificial marble with various kinds of colors such as transparent, white, black and grey. Color Grades: Able to confirm the coating colors of adhesives. Remover: For use in removing hardened substances and peel off parts of adhesives

Before Curing Appearance Liquid State

Colorless and Transparent

Before Curing Base Monomer Liquid State

Ethyl 2-Cyanoacrylate

Bonding Strength Shear 0

(Shear measured in psi for various materials) Material Shear Strengths (psi) (Substrate material bonded to substrate material) 203TX 212TX 214TX 225FTX 252TX 253TX PVC (Rigid)/PVC 1400 1400 1000 1400 1400 PMMA/PMMA 710 710 710 710 710 ABS/ABS 710 710 710 710 710 PC/PC 1000 1000 1000 1000 1000 Natural Rubber/Natural Rubber 57 57 100 70 57 57 Steel/Steel 2800 2800 2800 2840 2800 2800 Copper/Copper 2130 Phenolic Resin/Phenolic Resin 1000 Rigid PVC/Steel 1400 1400 1000 1400 1400 Aluminum/ABS 1000 1000 710 1000 1000 Phenolic Resin/Copper 1000 Neoprene Rubber/Steel 57 57 70 57 57 Neoprene Rubber/ABS 57 57 70 57 57 Balsa Wood/Balsa Wood 70

Bonding Strength Tensile 0

(Tensile measured in psi for various materials) Material Tensile Strengths (psi) (Substrate material bonded to substrate material) 203TX 212TX 214TX 225FTX 252TX 253TX PVC (Rigid)/PVC 5000 5000 3500 3840 5000 5000 PMMA/PMMA 5000 5000 2840 5000 5000 ABS/ABS 3600 3600 2990 3600 3600 PC/PC 5000 5000 3560 5000 5000 Natural Rubber/Natural Rubber 360 360 280 360 360 Steel/Steel 4600 4600 3500 4270 4600 4600 Copper/Copper 4550 Phenolic Resin/Phenolic Resin 4270 Rigid PVC/Steel 2600 2600 2560 2600 2600 Aluminum/ABS 2100 2100 2130 2100 2100 Phenolic Resin/Copper 3560 Neoprene Rubber/Steel 360 360 280 360 360 Neoprene Rubber/ABS 360 360 280 360 360

Characteristics Of Aron Alpha Cyanoacrylate Adhesives Characteri

Instant Bonding :Adhesion is achieved in a few seconds, It is well suited for increasing the efficiency of the manufacturing process. Easy to use: Adhesive is single component and heat treatment are not required. Perfect f

Features 0

No stringiness. Thixotropic property. Fast setting to a variety of materials. Good bonding strength to various materials. Good compatibility to dispensing machines.

Method Of Disposal 0

Expose the adhesives in the containers to moisture and light to let it harden slowly, and to treat it as waste plastics (drastic hardening may result in heating, pay attention to this situation). Please comply with local regulations when dispos

Precaution 0

When in contact with Skin Don't peel it off forcibly, instead use warm water or remover to rub it off. When in contact with Eyes It will damage the eyes to rub the eyes or to use solvents. Must rinse with large amount of water and get medical attention.

Setting Time 0

(in seconds for various materials) Material Setting Time (sec) (Substrate material bonded to substrate material) 203TX 212TX 214TX 225FTX 252TX 253TX PVC (Rigid)/PVC 5 3 5 5 5 10 PMMA (Polymethylmetacrylate)/PMMA 10 3 -- 10 5 15 ABS (Acrylonitrile butadiene styrene)/ABS 15 5 15 15 10 30 PC (Polycarbonate)/PC 15 5 -- 30 15 30 Natural Rubber/Natural Rubber 10 3 5 5 5 10 Steel/Steel 15 5 -- 20 10 30 Copper/Copper -- -- -- 3 -- -- Phenolic Resin/Phenolic Resin -- -- -- 5 -- -- Rigid PVC/Steel 15 5 -- 20 10 30 Aluminum/ABS 15 5 20 30 10 30 Phenolic Resin/Copper -- -- -- 5 -- -- Neoprene Rubber/Steel 15 5 -- 10 10 30 Neoprene Rubber/ABS 15 5 -- 10 10 30 Balsa Wood/Balsa Wood -- -- 10 -- -- 3

Specifications Bonding Atmosphere

22 to 24 ºC | 72 to 75 ºF

Specifications Bonding Strength To Electroplating

Good

Specifications Bonding Strength To Metal

Good

Specifications Bonding Strength To Plastic

Good

Specifications Bonding Strength To Rubber

Good

Specifications Color

Clear

Specifications Form Of Packing 20g

Good

Specifications Form Of Packing 50g

Good

Specifications Gap Fill

0.010"

Specifications Relative Humidity

58-62%

Specifications Series

200TX

Specifications Set Timepvc

5 s

Specifications Set Time Abs

15 s

Specifications Set Time Aluminum

30 s

Specifications Set Time Chroloprene

15 s

Specifications Set Time Epdm

3 s

Specifications Set Time Polycarbonate

30 s

Specifications Set Time Steel

20 s

Specifications Temperature Range

-65 ºF to +180 ºF

Specifications Tensile Shearing Strength Chroloprene

0.6 N/mm²

Specifications Tensile Shearing Strength Epdm

0.6

Specifications Tensile Shearing Strength Polycarbonate

6 N/mm²

Specifications Tensile Shear Strength For Metal

0.064 x 1.0 x 4.0 inch; bonded area 0.5 sq. inch

Specifications Tensile Shear Strength For Plastic And Rubber

0.1 x 1.0 x 4.0 inch; bonded area 0.5 sq.inch

Specifications Tensile Shear Strength Steel

4600 psi

Specifications Unit Size

20 gm tube