Axiom® ARC High-Speed Case/Tray Packer

Axiom® ARC High-Speed Case/Tray Packer

SKU:MAC-a7368d

Experience exceptional product control with the Axiom® ARC High-Speed Case/Tray Packer. Achieve speeds of up to 80 cases/min with unmatched efficiency and stability.

Regular price

$59,999.99

Regular price

Sale price

$59,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

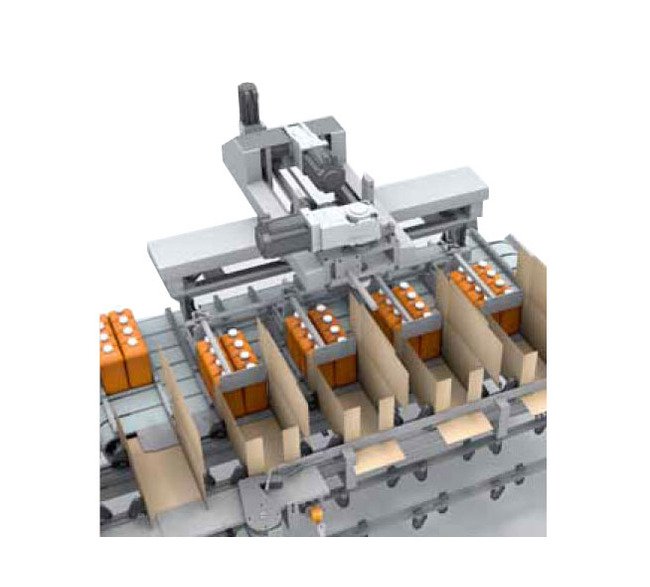

The Axiom® ARC High-Speed Case/Tray Packer offers exceptional product control and efficiency with speeds of up to 80 cases per minute. Designed for stability and versatility, it handles various product types and package sizes effortlessly. Featuring a continuous motion loader, tool-free changeover, and advanced product handling technologies, this packer ensures quick, precise, and reliable performance for institutional and consumer needs.

Product Specifications

Additional Information Additional Information

Combining maximum speed and flexibilityServo driven Axiom® continuous motion case/tray packers utilize smooth, continuous motion in all sections of the machines. To maximize throughput and improve product stability, cases never stop moving from loading to discharge. Servo functions reliably and accurately pack cartons, bottles, cans, jars, and jugs using innovative infeed technology and high-speed case loading methods with precise product control.

Air Pressure Air Pressure

90 psi | 6.2 bar

Air Pressure Air Pressure Drop

One

Case Size Range Maximum Case Size

12 x 21 x 13 in

Case Size Range Minimum Case Size

6 x 8 x 3.5 in

Case Size Range Note For Case Size Range

L = Travel DirectionLength x Width x Vertical

Features Features

Efficient Pack-Pattern LoadingAll Axiom® loading techniques are designed to provide superior performance and reliability. Axiom® continuous motion servo technology delivers smooth, harmonious performance during case loading, while maintaining accurate product control for a wide variety of pack-patterns. Patented design and precise servo control enable:Quick and repeatable changeoversGreater speedGentler product handlingIncreased flexibilityFlexible Conveying and Product HandlingA variety of advanced infeed solutions optimize performance for specific product types while maintaining gentle product handling to ensure the highest package integrity.High-Speed Lane Divider - Easily handles round, rectangular, oval, and irregularly shaped products. The high-speed lane divider will ensure balanced lanes and gentle continuous motion product handling.Smartrak® II - Mass flow infeed design eliminates soft bottle bridging and removes gaps to ensure pack-pattern accuracy and continuous product flow. Distinguishing features include modulated speed control programming for surge pressure relief at the choke point, single solid adjustment cross-members, tool-free clamps and pinned lane guide adjustment positions for stable operation and quick, accurate changeovers. By eliminating many mechanical changeover adjustments and replacing them with a one-clamp design, changeovers are seamless and fast.Recirculating Conveyor - A complete recirculating loop system controls product population and reduces line pressure as products are distributed into lanes.Pack-Pattern Collating RedefinedDouglas redefines the role of product pattern collating in high efficiency lines. Our patented technologies dramatically improve line throughput and production volume while providing remarkably stable product handling.Slipstream⢠- Patented pinless metering uses slip sheet methodology and servo technology to gently collate bottled, cartoned, canned and other products into pack-patterns without the use of tampers or escapement pins. Remarkable stability control results in faster handling than traditional metering methods. Tool-free changeovers and the intuitive HMI control panel also increase productivity.The appropriate technology is determined based on speeds and your product. Slipstream⢠offers more stability as product moves faster, especially with unstable product or odd size/shaped packaging.Continuous motion partition insertion - When product partitions are included, servo controls precisely position and insert partitions without interruption.More Flexibility, More Accuracy, More Performance.Most changeovers are accomplished through a simple menu-driven process on the HMI. Operators simply select from pre-programmed recipes for specific products, and servo motors precisely make the required adjustments.Recipe control of machine motions makes changeover precise and repeatable, minimizing ramp-up time.

Note Note

Specifications subject to change without notice.

Power Alternating Current Ac Voltage

480 V

Power Frequency

50 Hz | 60 Hz

Power Note For Power

Other Power Sources Available.

Power Number Of Phase

3

Power Voltage Drop

One Glue Drop | One Main Drop

Specifications Adjustments

Tool-free changeover, HMI selectable recipes, threaded screws, handwheels, and handknobs with position pointers and digital scales.

Specifications Brand

Axiom® | Douglas

Specifications Case Handling

6 ft magazine, vacuum pick and blank setup into flighted chain.

Specifications Case Sealing

NORDSON® ProBlue® 15 glue system Continuous motion flap folding and compression system.

Specifications Case Types

Wrap around cases (RSC, POL, FOL or harness style flaps), pre-glued knockdown KD cases, and trays.

Specifications Drive Functions

Servo

Specifications Electrical

Rockwell Automation (AB) programmable logic controller, servos, drives and PV+ HMI.NEMA 12 wiring and enclosures.Washdown (optional).

Specifications Framefinish

Powder coated tubular cold rolled steel, gray metallic, Dupont 616.

Specifications Guarding

Category 3 guarding.Full length polycarbonate with extruded anodized aluminum frames.

Specifications Package Type

Case | Tray

Specifications Product Loading

High speed continuous motion ARC loader, product containment and product stabilizing features are available.

Specifications Speed

Up to 80 cases/min