Beko BEKOKAT 210 scfm Hydrocarbon Removal Air Compressor

Beko BEKOKAT 210 scfm Hydrocarbon Removal Air Compressor

SKU:BEK-479eb1

Experience the pinnacle of compressed air treatment with Beko BEKOKAT 210 scfm Advanced Hydrocarbon Removal Air Compressor. Achieve oil-free air of unmatched purity and reliability.

Regular price

$4,999.99

Regular price

Sale price

$4,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Beko BEKOKAT 210 scfm Advanced Hydrocarbon Removal System Air Compressor is a pinnacle of compressed air treatment technology. With a flow rate of 210 scfm, this system boasts a connection type of 1-1/2 in NPT, operating at 230V/3-phase/60Hz. Meeting EN ISO 9001:2000 and TÜV Nord certifications for ISO 8573 Class 1, it ensures a maximum pressure of 175 psi, generating oil-free compressed air with ≤ 0.01 mg/m³ oil content. Ideal for various industries such as pharmaceutical, chemical, and medical, the BEKOKAT system guarantees reliable, efficient, and environmentally friendly operation, delivering air of unmatched purity and quality.

Product Specifications

Additional Information 0

This calls for a fresh approach and advanced solutions. Beko's catalyst technology sets a new benchmark in compressed air treatment products that overcomes these limitations by offering users a technology that will produce what is in essence oil-free air from a single device, regardless of operating conditions.Intensive research and development work was conducted in order to exploit the theoretical possibilities of catalyst technology, which has resulted in the BEKOKAT - a device that combines superior efficiency with the highest level of reliability.The BEKOKAT represents a real technological breakthrough never before offered.

Applications Chemical Industry

Chemical production is central to the modern world economy. From basic to specialty chemicals, life sciences to consumer products, one minor miscalculation can be disastrous. The use of BEKOKAT in conjunction with proper protocol can only lead to results that are maximally optimized.

Applications Continuous Oil Free Air

A constant supply of oil-free compressed air with a barely detectable maximum residual oil content of 0.003 mg/m³With this high level of efficiency, the BEKOKAT devices can easily sail past the stringent oil content stipulations of DIN EN8573-1 / ISO 8573 Class 1 - and beyond. At the same time, the new functional principle breaks down both technical and economic barriers that are typically associated with conventional compressed air treatment solutions, especially where those applications with extremely high requirements are concerned.The oil-free and dry compressed air can then be used for the given application; the remaining water is simply discharged. Consequently, BEKOKAT systems are not only highly effective, but also very environmentally friendly.

Applications Food And Beverage And Tobacco Industry

FDA and/or USDA approved facilities must meet some of the most stringent requirements in terms of overall cleanliness and purity in their production methods. The BEKOKAT hydrocarbon removal systems ensure these requirements are met on a daily basis, 24 / 7 / 365.

Applications Medical Industry

There is no application more critical than having another human life in your hands. From the beginning stages of diagnosis to final recovery, medical applications of all kinds require the most sterile, pure air available. BEKOKAT systems not only eliminate oil, but bacteria as well- The perfect solution.

Applications Packaging Industry

The quality of air used in the conveyance and packaging of food must be of equal quality and purity as the air used during processing and production. The adherence to strict packaging guidelines and laws is vastly improved by implementing a BEKOKAT device to any line.

Applications Pharmaceutical Industry

Whether an oil-free compressor is currently employed or not, imagine the contamination of a multi-million dollar batch run of pharmaceuticals because of a slowly deteriorating crankcase main seal. The subsequent incineration of that batch is pure loss. The BEKOKAT offers unparalleled production protection.

Applications Surface Industry

The introduction of hydrocarbons into the air line of any surface coating or spray application can be detrimental to the finish or final product quality. With the addition of a BEKOKAT system and the guaranteed residual oil content downstream that perfect paint job can finally become a reality.

Catalyst Function 0

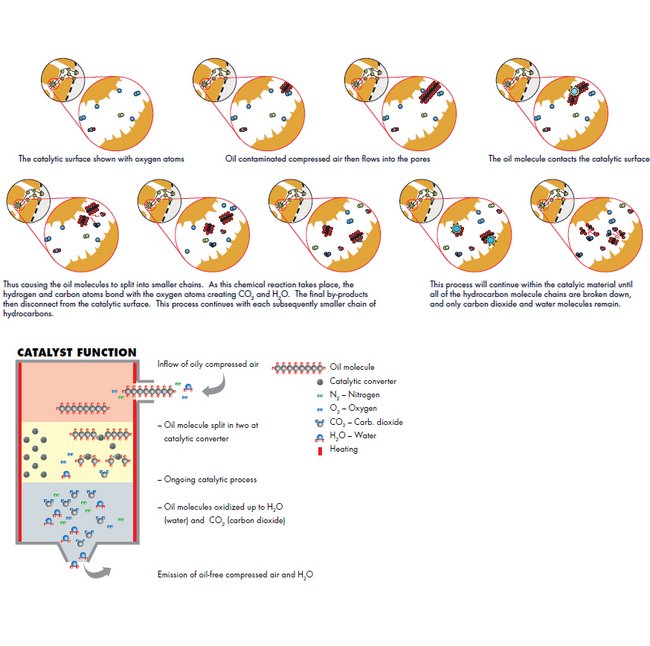

Function of The Catalytic ConverterThe heterogene catalysis of the BEKOKAT has the following reaction stagesPart 1: Diffusion of the reaction particle on the catalytic surfacePart 2: Diffusion of the reaction particle within the pores of the catalystPart 3: AdsorptionPart 4: Surface reactionPart 5: De-sorption of the reaction productsPart 6: Diffusion of the products out of the poresPart 7: Diffusion of the products into the homogenous phase

Features 0

High-Quality Compressed Air from BekoThe quality of your compressed air.ReliableThe highest level of operational reliability is guaranteed with every product that Beko manufactures.EfficientMaximum energy efficiency and conservation are guiding principles of every product design.EconomicProducts that provide the quickest return on investment in the industry with the least amount of risk.EffectiveGerman engineered with no compromises on quality.ExperienceMore than 25 years of industry leading experience stands behind our entire product offering.SolutionsYour single source for a range of performance compressed air products designed to work in synergy.

Model Information 0

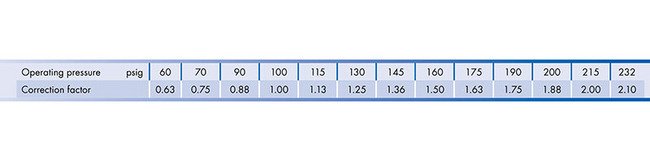

Attainable residual oil outlet content is = 0.003 mg/m³ and under optimum conditions 0.001 mg/m³ is attainable.The residual oil content can be monitored continuously using BEKO METPOINT OCV devices.Other models or voltages are available upon request.Model CC 210-NA and above are constructed with an open frame (no housing).All BEKOKAT units are rated for an operating pressure of 100 psig and a max. operating pressure of either 175 or 232 psig.The performance values refer to an inlet pressure of 100 psig. In the case of a different inlet pressure, please use the respective correction factor from the table above.Example: CC 105-NACapacity at 100 psig /+100 ºF inlet: 105 scfmFactor for 70 psig: 0.75Capacity at 70 psig operating pressure:105 scfm x 0.75 = 78.75 scfm

Note 0

Compressed air treatment and condensate technology. The complete program. Worldwide.Subject to technical changes without prior notice; the information provided does not represent characteristics of state within the meaning of the German Civil Code (BGB).

Product Line Features Constant Even Temperature

For compressed air treatment using a BEKOKAT unit, a pressure vessel is filled with a specially developed granulate. The entire vessel is heated to an operating temperature of 302 ºF. The oil particles in the compressed air stream that flow through the heated vessel are completely transformed inside the pores of the catalyst granulate, the only by products being water and carbon dioxide.

Product Line Features Environmentally Friendly

Produces oil-free condensate of the same quality as the compressed air stream.

Product Line Features Independent Of Conditions

Stable residual oil content throughout the year, in any climate.

Product Line Features Maximum Confidence

After rigorous testing by the world renowned TÜV Nord Group, the BEKOKAT devices have obtained one of the most recognizable certifications in our industry. The installation of one of our devices guarantees your results with fully supported performance documentation. You cannot find this anywhere else in the world.

Product Line Features Oil Free Compressed Air

Continuously produced from any compressor type down to 0.003 mg/m³.

Product Line Features Partial Load Operation

Maximum process reliability regardless of production fluctuations.

Product Line Features Responsive Controls

Ensure machine safety and operational accuracy.

Specifications Brand

Beko | BEKOKAT

Specifications Concentration Of Total Oil

≤ 0.01 mg/m³

Specifications Connection

1-1/2 in

Specifications Connection Type

National Pipe Thread (NPT)

Specifications Dimension A

63 in

Specifications Dimension B

52 in

Specifications Dimension C

30 in

Specifications Flow Rate

210 scfm

Specifications Frequency

60 Hz

Specifications Industry Standards

EN ISO 9001:2000 | TÜV Nord Certified to ISO 8573 Class 1

Specifications Input Power

5.10 kW

Specifications Maximum Pressure

175 psi

Specifications Operating Temperature

302 ºF

Specifications Phase

3

Specifications Power Consumption

2.17 kW

Specifications Voltage

230 V

Specifications Weight

693 lb