Beko Clearpoint 125 Water Separator - 125 scfm Flow Rate

Beko Clearpoint 125 Water Separator - 125 scfm Flow Rate

SKU:BEK-9df86f

Achieve 99% condensate removal with Beko Clearpoint 125 Water Separator - optimal protection for compressed air systems.

Regular price

$399.99

Regular price

Sale price

$399.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Beko Clearpoint 125 Water Separator ensures optimal condensate removal with a 99% removal rate and no re-entrainment, meeting stringent industry standards. With a flow-optimized housing and high reliability components, this unit delivers efficient and economic compressed air treatment. Engineered with German precision and over 25 years of experience, it offers high-quality, corrosion-resistant performance for institutional and government buyers.

Product Specifications

Additional Information 0

The electronically level controlled BEKOMAT®In addition to the well known reliability of a BEKOMAT®, this combination offers additional advantages: Easy to read and informative displayFree contact for relaying a fault signal to a control centerCondensate discharge at the rear through a barbed hose connector, which is ideal for installations close to a wall

Cycle Information 0

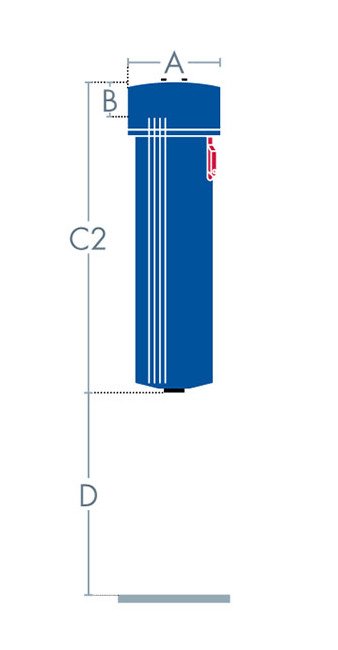

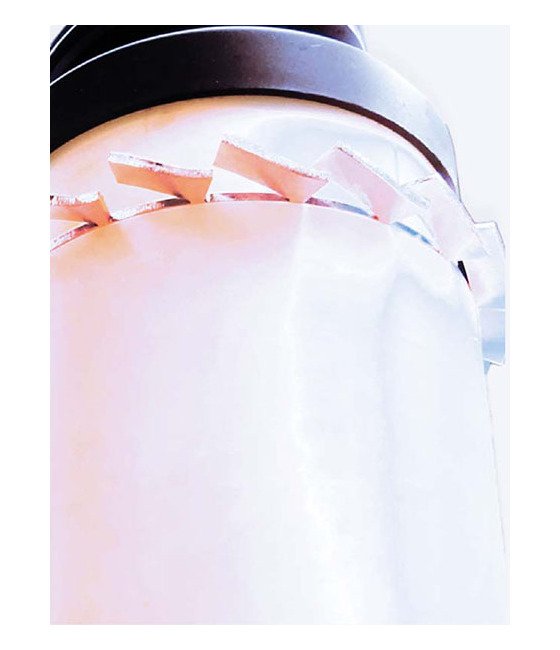

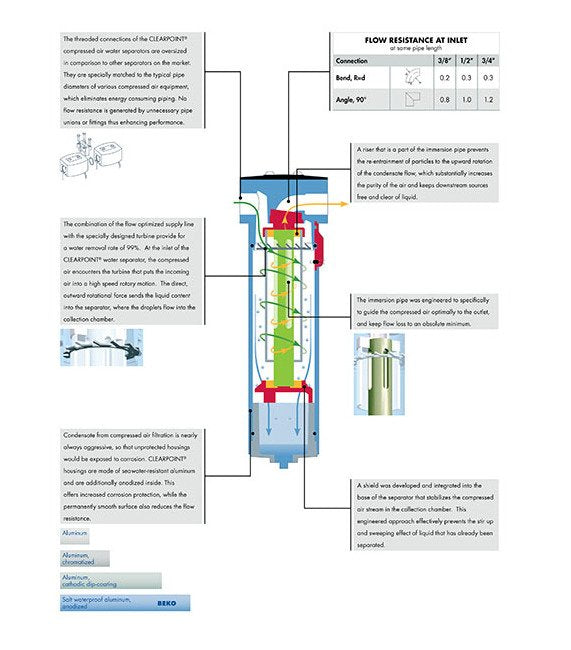

The threaded connections of the Clearpoint compressed air water separators are oversized in comparison to other separators on the market. They are specially matched to the typical pipe diameters of various compressed air equipment, which eliminates energy consuming piping. No flow resistance is generated by unnecessary pipe unions or fittings thus enhancing performance.The combination of the flow optimized supply line with the specially designed turbine provide for a water removal rate of 99%. At the inlet of the Clearpoint water separator, the compressed air encounters the turbine that puts the incoming air into a high speed rotary motion. The direct, outward rotational force sends the liquid content into the separator, where the droplets flow into the collection chamber.The combination of the flow optimized supply line with the specially designed turbine provide for a water removal rate of 99%. At the inlet of the Clearpoint water separator, the compressed air encounters the turbine that puts the incoming air into a high speed rotary motion. The direct, outward rotational force sends the liquid content into the separator, where the droplets flow into the collection chamber.Condensate from compressed air filtration is nearly always aggressive, so that unprotected housings would be exposed to corrosion. Clearpoint housings are made of seawater-resistant aluminum and are additionally anodized inside. This offers increased corrosion protection, while the permanently smooth surface also reduces the flow resistance.AluminumAluminum chromatizedAluminum, cathodic dip-coatingSalt waterproof aluminum, anodizedA riser that is a part of the immersion pipe prevents the re-entrainment of particles to the upward rotation of the condensate flow, which substantially increases the purity of the air and keeps downstream sources free and clear of liquid.The immersion pipe was engineered to specifically to guide the compressed air optimally to the outlet, and keep flow loss to an absolute minimum.A shield was developed and integrated into the base of the separator that stabilizes the compressed air stream in the collection chamber. This engineered approach effectively prevents the stir up and sweeping effect of liquid that has already been separated.

Features 0

High-Quality Compressed Air from BekoThe quality of your compressed air.ReliableThe highest level of operational reliability is guaranteed with every product that Beko manufactures.EfficientMaximum energy efficiency and conservation are guiding principles of every product design.EconomicProducts that provide the quickest return on investment in the industry with the least amount of risk.EffectiveGerman engineered with no compromises on quality.ExperienceMore than 25 years of industry leading experience stands behind our entire product offering.SolutionsYour single source for a range of performance compressed air products designed to work in synergy.

Filter Element Information Grade A Approvals For Element Grade A

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade A Element Type For Element Grad

Activated Carbon

Filter Element Information Grade A Micron Rating For Element Gra

0.01 µm

Filter Element Information Grade A Oil Vapor Content For Element

0.003 mg/m³

Filter Element Information Grade A Pressure For Element Grade A

0.70 psid

Filter Element Information Grade C Approvals For Element Grade C

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade C Element Type For Element Grad

Coarse

Filter Element Information Grade C Micron Rating For Element Gra

25 µm

Filter Element Information Grade C Oil Carryover For Element Gra

5 mg/m³

Filter Element Information Grade C Pressure For Element Grade C

0.54 psid

Filter Element Information Grade F Approvals For Element Grade F

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade F Element Type For Element Grad

Fine

Filter Element Information Grade F Micron Rating For Element Gra

1 µm

Filter Element Information Grade F Oil Carryover For Element Gra

0.1 mg/m³

Filter Element Information Grade F Pressure For Element Grade F

0.86 psid

Filter Element Information Grade G Approvals For Element Grade G

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade G Element Type For Element Grad

General

Filter Element Information Grade G Micron Rating For Element Gra

5 µm

Filter Element Information Grade G Oil Carryover For Element Gra

1 mg/m³

Filter Element Information Grade G Pressure For Element Grade G

0.70 psid

New Filter Material Borosilicate Fibers For New Filter Material

<2 µm

New Filter Material Cavity Volume For New Filter Material

98 %

New Filter Material Material Emissions For New Filter Material

Not possible

New Filter Material Material Volume For New Filter Material

2 %

New Filter Material Maximum Temperature 1 H For New Filter Mater

212 ºF

New Filter Material Maximum Temperature For New Filter Material

176 ºF

New Filter Material Mechanical Stability Through For New Filter

Thermally fused borosilicate and polyester fibers

New Filter Material Separation Area For New Filter Material

400 to 500 %

Old Filter Material Borosilicate Fibers For Old Filter Material

2 to 10 µm

Old Filter Material Cavity Volume For Old Filter Material

95 %

Old Filter Material Material Emissions For Old Filter Material

Possible

Old Filter Material Material Volume For Old Filter Material

5 %

Old Filter Material Maximum Temperature For Old Filter Material

248 ºF

Old Filter Material Mechanical Stability Through For Old Filter

Binding agents

Old Filter Material Separation Area For Old Filter Material

100 %

Specifications Brand

Beko | Clearpoint

Technical Data Volume

0.26 gal