Beko Clearpoint 330 scfm Standard Threaded Air Filter

Beko Clearpoint 330 scfm Standard Threaded Air Filter

SKU:BEK-d5d363

Enhance air quality with Beko Clearpoint 330 scfm Air Filter. Reliable, efficient, and compliant with industry standards.

Regular price

$499.99

Regular price

Sale price

$499.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Beko Clearpoint 330 scfm Standard Threaded Air Filter ensures optimum filtration efficiency with its new filter material featuring ultra-low micron ratings. Engineered for institutional use, it offers maximum reliability, easy maintenance, and energy-efficient elements, meeting stringent procurement standards for quality and performance.

Product Specifications

Additional Information 0

The electronically level controlled BEKOMAT®In addition to the well known reliability of a BEKOMAT®, this combination offers additional advantages: Easy to read and informative displayFree contact for relaying a fault signal to a control centerCondensate discharge at the rear through a barbed hose connector, which is ideal for installations close to a wall

Cycle Information 0

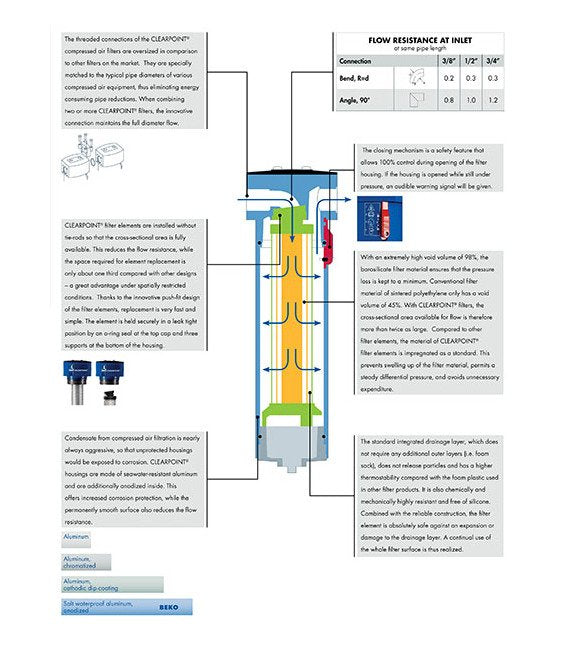

The threaded connections of the Clearpoint compressed air filters are oversized in comparison to other filters on the market. They are specially matched to the typical pipe diameters of various compressed air equipment, thus eliminating energy consuming pipe reductions. When combining two or more Clearpoint filters, the innovative connection maintains the full diameter flow.Clearpoint filter elements are installed without tie-rods so that the cross-sectional area is fully available. This reduces the flow resistance, while the space required for element replacement is only about one third compared with other designs- a great advantage under spatially restricted conditions. Thanks to the innovative push-fit design of the filter elements, replacement is very fast and simple. The element is held securely in a leak tight position by an o-ring seal at the top cap and three supports at the bottom of the housing.Condensate from compressed air filtration is nearly always aggressive, so that unprotected housings would be exposed to corrosion. Clearpoint housings are made of seawater-resistant aluminum and are additionally anodized inside. This offers increased corrosion protection, while the permanently smooth surface also reduces the flow resistance.AluminumAluminum, chromatizedAluminum, cathodic dip-coatingSalt waterproof aluminum, anodizedThe closing mechanism is a safety feature that allows 100% control during opening of the filter housing. If the housing is opened while still under pressure, an audible warning signal will be given.With an extremely high void volume of 98%, the borosilicate filter material ensures that the pressure loss is kept to a minimum. Conventional filter material of sintered polyethylene only has a void volume of 45%. With Clearpoint filters, the cross-sectional area available for flow is therefore more than twice as large. Compared to other filter elements, the material of Clearpoint filter elements is impregnated as a standard. This prevents swelling up of the filter material, permits a steady differential pressure, and avoids unnecessary expenditure.The standard integrated drainage layer, which does not require any additional outer layers (i.e. foam sock), does not release particles and has a higher thermostability compared with the foam plastic used in other filter products. It is also chemically and mechanically highly resistant and free of silicone. Combined with the reliable construction, the filter element is absolutely safe against an expansion or damage to the drainage layer. A continual use of the whole filter surface is thus realized.

Features 0

High-Quality Compressed Air from BekoThe quality of your compressed air.ReliableThe highest level of operational reliability is guaranteed with every product that Beko manufactures.EfficientMaximum energy efficiency and conservation are guiding principles of every product design.EconomicProducts that provide the quickest return on investment in the industry with the least amount of risk.EffectiveGerman engineered with no compromises on quality.ExperienceMore than 25 years of industry leading experience stands behind our entire product offering.SolutionsYour single source for a range of performance compressed air products designed to work in synergy.

Filter Element Information Grade A Approvals For Element Grade A

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade A Element Type For Element Grad

Activated Carbon

Filter Element Information Grade A Micron Rating For Element Gra

0.01 µm

Filter Element Information Grade A Oil Vapor Content For Element

0.003 mg/m³

Filter Element Information Grade A Pressure For Element Grade A

0.70 psid

Filter Element Information Grade C Approvals For Element Grade C

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade C Element Type For Element Grad

Coarse

Filter Element Information Grade C Micron Rating For Element Gra

25 µm

Filter Element Information Grade C Oil Carryover For Element Gra

5 mg/m³

Filter Element Information Grade C Pressure For Element Grade C

0.54 psid

Filter Element Information Grade F Approvals For Element Grade F

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade F Element Type For Element Grad

Fine

Filter Element Information Grade F Micron Rating For Element Gra

1 µm

Filter Element Information Grade F Oil Carryover For Element Gra

0.1 mg/m³

Filter Element Information Grade F Pressure For Element Grade F

0.86 psid

Filter Element Information Grade G Approvals For Element Grade G

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade G Element Type For Element Grad

General

Filter Element Information Grade G Micron Rating For Element Gra

5 µm

Filter Element Information Grade G Oil Carryover For Element Gra

1 mg/m³

Filter Element Information Grade G Pressure For Element Grade G

0.70 psid

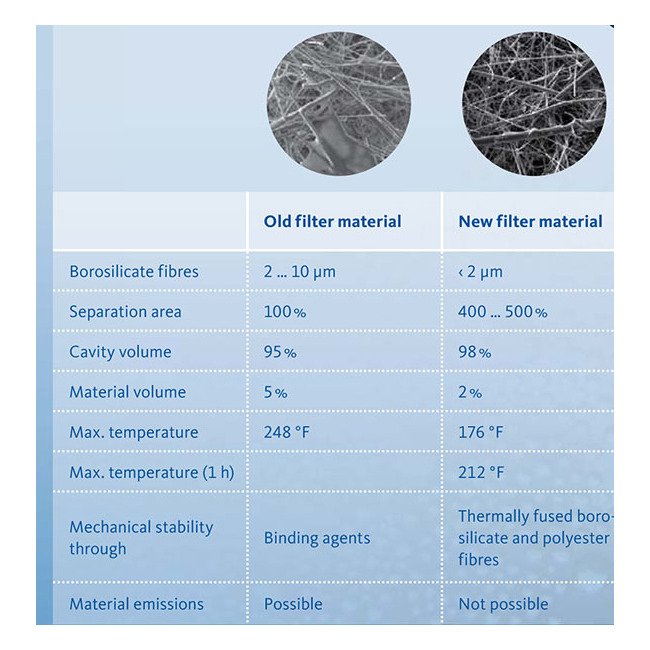

New Filter Material Borosilicate Fibers For New Filter Material

<2 µm

New Filter Material Cavity Volume For New Filter Material

98 %

New Filter Material Material Emissions For New Filter Material

Not possible

New Filter Material Material Volume For New Filter Material

2 %

New Filter Material Maximum Temperature 1 H For New Filter Mater

212 ºF

New Filter Material Maximum Temperature For New Filter Material

176 ºF

New Filter Material Mechanical Stability Through For New Filter

Thermally fused borosilicate and polyester fibers

New Filter Material Separation Area For New Filter Material

400 to 500 %

Old Filter Material Borosilicate Fibers For Old Filter Material

2 to 10 µm

Old Filter Material Cavity Volume For Old Filter Material

95 %

Old Filter Material Material Emissions For Old Filter Material

Possible

Old Filter Material Material Volume For Old Filter Material

5 %

Old Filter Material Maximum Temperature For Old Filter Material

248 ºF

Old Filter Material Mechanical Stability Through For Old Filter

Binding agents

Old Filter Material Separation Area For Old Filter Material

100 %

Specifications Brand

Beko | Clearpoint

Technical Data Volume

0.78 gal