Beko Clearpoint 3800 scfm Flange Water Separator

Beko Clearpoint 3800 scfm Flange Water Separator

SKU:BEK-e6f462

Enhance air quality with the Beko Clearpoint 3800 scfm Flange Water Separator, providing energy-efficient, reliable air treatment.

Regular price

$2,399.99

Regular price

Sale price

$2,399.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Beko Clearpoint 3800 scfm Flange Water Separator is engineered for energy efficiency and reliability in processing large volumes of compressed air. Featuring a high-quality, energy-efficient filter medium and a top-loading design for easy maintenance, this water separator ensures maximum operational performance. With ASME approval and industry-leading material quality, it offers exceptional reliability and ease of installation. The Beko Clearpoint 3800 scfm Flange Water Separator is a top choice for institutions requiring superior air treatment solutions.

Product Specifications

Additional Information 0

The electronically level controlled BEKOMAT®The BEKOMAT® intelligent, zero air loss drain is standard on all flanged model sizes and offers additional advantages: Low maintenance with a 1,000,000 cycle ratingPotential free contact for relaying a fault signal to a control centerSensor controlled operation that is safe for all condensate types

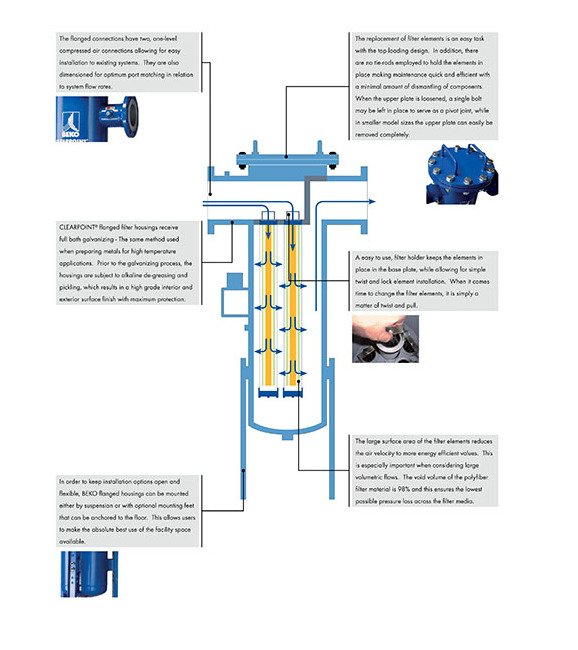

Cycle Information 0

The flanged connections have two, one-level compressed air connections allowing for easy installation to existing systems. They are also dimensioned for optimum port matching in relation to system flow rates.Clearpoint flanged filter housings receive full bath galvanizing - The same method used when preparing metals for high temperature applications. Prior to the galvanizing process, the housings are subject to alkaline de-greasing and pickling, which results in a high grade interior and exterior surface finish with maximum protection.In order to keep installation options open and flexible, Beko flanged housings can be mounted either by suspension or with optional mounting feet that can be anchored to the floor. This allows users to make the absolute best use of the facility space available.The replacement of filter elements is an easy task with the top-loading design. In addition, there are no tie-rods employed to hold the elements in place making maintenance quick and efficient with a minimal amount of dismantling of components. When the upper plate is loosened, a single bolt may be left in place to serve as a pivot joint, while in smaller model sizes the upper plate can easily be removed completely.A easy to use, filter holder keeps the elements in place in the base plate, while allowing for simple twist and lock element installation. When it comes time to change the filter elements, it is simply a matter of twist and pull.The large surface area of the filter elements reduces the air velocity to more energy efficient values. This is especially important when considering large volumetric flows. The void volume of the polyfiber filter material is 98% and this ensures the lowest possible pressure loss across the filter media.

Features 0

High-Quality Compressed Air from BekoThe quality of your compressed air.ReliableThe highest level of operational reliability is guaranteed with every product that Beko manufactures.EfficientMaximum energy efficiency and conservation are guiding principles of every product design.EconomicProducts that provide the quickest return on investment in the industry with the least amount of risk.EffectiveGerman engineered with no compromises on quality.ExperienceMore than 25 years of industry leading experience stands behind our entire product offering.SolutionsYour single source for a range of performance compressed air products designed to work in synergy.

Filter Element Information Grade A Approvals For Element Grade A

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade A Element Type For Element Grad

Activated Carbon

Filter Element Information Grade A Micron Rating For Element Gra

0.01 µm

Filter Element Information Grade A Oil Vapor Content For Element

0.003 mg/m³

Filter Element Information Grade A Pressure For Element Grade A

0.70 psid

Filter Element Information Grade C Approvals For Element Grade C

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade C Element Type For Element Grad

Coarse

Filter Element Information Grade C Micron Rating For Element Gra

25 µm

Filter Element Information Grade C Oil Carryover For Element Gra

5 mg/m³

Filter Element Information Grade C Pressure For Element Grade C

0.54 psid

Filter Element Information Grade F Approvals For Element Grade F

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade F Element Type For Element Grad

Fine

Filter Element Information Grade F Micron Rating For Element Gra

1 µm

Filter Element Information Grade F Oil Carryover For Element Gra

0.1 mg/m³

Filter Element Information Grade F Pressure For Element Grade F

0.86 psid

Filter Element Information Grade G Approvals For Element Grade G

ASME Coded Vessel with 'U' Stamp as standard (CRN Optional) Flange Filters Only

Filter Element Information Grade G Element Type For Element Grad

General

Filter Element Information Grade G Micron Rating For Element Gra

5 µm

Filter Element Information Grade G Oil Carryover For Element Gra

1 mg/m³

Filter Element Information Grade G Pressure For Element Grade G

0.70 psid

New Filter Material Borosilicate Fibers For New Filter Material

<2 µm

New Filter Material Cavity Volume For New Filter Material

98 %

New Filter Material Material Emissions For New Filter Material

Not possible

New Filter Material Material Volume For New Filter Material

2 %

New Filter Material Maximum Temperature 1 H For New Filter Mater

212 ºF

New Filter Material Maximum Temperature For New Filter Material

176 ºF

New Filter Material Mechanical Stability Through For New Filter

Thermally fused borosilicate and polyester fibers

New Filter Material Separation Area For New Filter Material

400 to 500 %

Old Filter Material Borosilicate Fibers For Old Filter Material

2 to 10 µm

Old Filter Material Cavity Volume For Old Filter Material

95 %

Old Filter Material Material Emissions For Old Filter Material

Possible

Old Filter Material Material Volume For Old Filter Material

5 %

Old Filter Material Maximum Temperature For Old Filter Material

248 ºF

Old Filter Material Mechanical Stability Through For Old Filter

Binding agents

Old Filter Material Separation Area For Old Filter Material

100 %

Specifications Brand

Beko | Clearpoint

Specifications Flange Size

4 to 12 in