Carbon Steel USS Flat Washer, 1 1/4 in - Plain Finish

Carbon Steel USS Flat Washer, 1 1/4 in - Plain Finish

SKU:TRA-9b32d1

High-quality Carbon Steel USS Flat Washer with Plain finish for durable and secure structural connections.

Regular price

$14.99

Regular price

Sale price

$14.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Carbon Steel USS Flat Washer in a Plain finish is a key component for securing structural connections with precision. Featuring a Wide Series design and a Size of 1 1/4 inches, this washer offers exceptional durability and weight-bearing capabilities. Crafted to meet the highest industry standards, this USS Flat Washer is ideal for a range of applications requiring reliable fastening solutions.

Product Specifications

Additional Information Additional Information

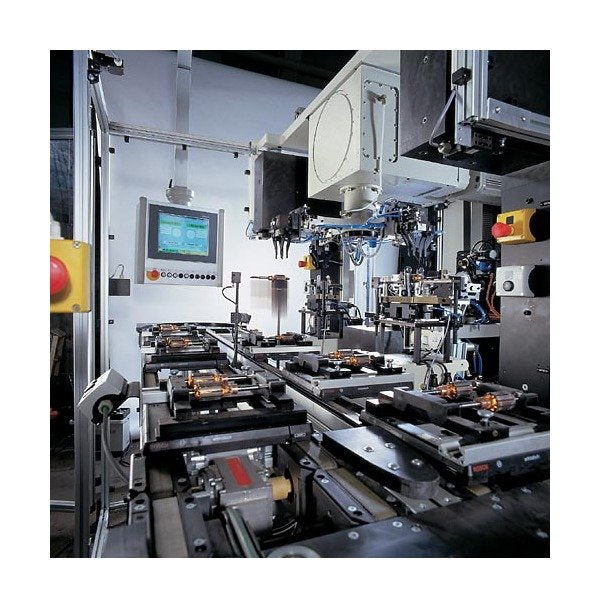

Photo based operating manual for conversion of machinePicture and text based fault diagnosisTeleservice for measuring and control system

Commutator Armature Commutator Armature Diameter

24 to 82 mm

Commutator Armature Commutator Armature Length

69 to 250 mm

Commutator Armature Commutator Armature Weight

0.1 to 2 kg

Commutator Armature Stack Height

12 to 65 mm

Correction Methods Correction Methods

Profile milling:Polar unbalance correction at the correct location, suitable for most applications.Polar slot-milling:The milling spindle with twin cutter is displaced axially to shift the effect of the milling operation to the polar direction of the unbalance.Slot-milling:A variable method for quasi-polar or component correction. High flexibility through employment of single or multiple cutters and adaptation of the component angle.All correction methods can be used for armatures with inclined or straight stack slots. In addition to material removal by plunge milling, weight removal can be increased by controlled axial cutter advancing.

Design Design

Four-station machine with fully automatic sequence of operations. Station-to-station transfer and integration with peripheral equipment through integrated rotary transfer system.Work-pieces can be delivered to the machine by conveyor belt or on pallets.

Machine Machine Depth B

2700 mm

Machine Machine Height C

2780 mm

Machine Machine Width A

1720 mm

Machine Note For Machine Dimensions

Data non-binding, dependent on the respective equipment supplied

Options Axial Clamping In The Milling Station Order Number

R0190109.01

Options Chip Extractor Order Number

R0190104.01

Options Measuring Unit Order Number Cab 850

R0190101.01

Options Options

Axial Clamping in the Milling Station | Chip-Extractor | Compact Swiveling Gripper | Measuring Unit (CAB 850) | Pneumatic Sliding Spindle | Unloading Equipment with OT Belt

Options Unloading Equipment Order Number With Ot Belt

R0190107.01

Range Of Application Range Of Application

Measurement and correction of unbalance of armatures of various sizes.Application of the machine in production lines for large rotor volumes.Unbalance correction by milling into the stack (profile/slot milling) in one or two planes.

Technical Data Achievable Tolerance

0.4 g/mm

Technical Data Air Consumption

2.5 m³/h

Technical Data Air Pressure

450 kPa

Technical Data Balancing Speed

1500 to 2100 min-1

Technical Data Basic Machine Order Number

R0190100.01

Technical Data Benefits

Polar profile milling

Technical Data Brands

SCHENCK

Technical Data Change Over Time

5 to 15 min

Technical Data Cycle Time Axial Milling

6 to 8 seconds

Technical Data Cycle Time Plunge Milling

6 seconds

Technical Data Measuring Uncertainty

0.02 to 0.1 g/mm

Technical Data Measuring Unit

CAB 850

Technical Data Power Consumption

10 kV·A