CeramiX® 14 Inch Abrasive Nylon Wheel Brush

CeramiX® 14 Inch Abrasive Nylon Wheel Brush

SKU:ABR-6eef68

Enhance surface finishing with the cutting-edge CeramiX® 14 Inch Abrasive Nylon Wheel Brush. Ideal for deburring and edge radiusing.

Regular price

$39.99

Regular price

Sale price

$39.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Enhance your surface finishing with the CeramiX® 14 Inch Abrasive Nylon Wheel Brush. Crafted with proprietary CeramiX® filament, this brush offers up to 5 times faster cutting action than traditional filaments, ensuring consistent performance. Ideal for deburring, surface finishing, and edge radiusing, this brush delivers optimal results at recommended speeds, maximizing efficiency and precision.

Product Specifications

Accessories

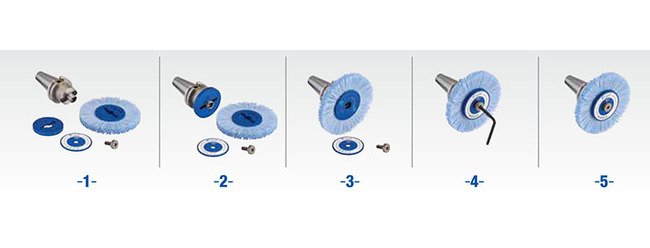

Wheel Brush Adapter PlatesDescription - These slip-fit metal adapters are used for mounting nylon abrasive wheel brushes onto smaller shafts. Sold in pairs. Available for 4-1/4" and 5-1/4" brush ID wheels and 2" brush ID wheels.Part Number - 35040Adapters Fits Arbor Hole - 5-1/4 in. Adapter Inside Diameter (ID) - 2 in.Keyway Size - 1/2 x 1/4 (2)Wheel Brush Adapter Plates for CNC Machine Shell Mill HoldersTanis®’ Wheel Brush Adapter, designed by our engineering team to support automated deburring, allows simple attachment of wheel brushes to CNC machines. No hassle coupling is accomplished by placing the adapter plates on both sides of the wheel brush and securing the device with a bolt to the shell mill holder. Set screws prevent the brush from rotating.Part Number - 35915Face Width - StandardBrush Inside Diameter (ID) - 5-1/4 in.Pilot - 1-1/4 in.Wheel Brush Adapter Plates for CNC Machine Shell Mill HoldersTanis®’ Wheel Brush Adapter, designed by our engineering team to support automated deburring, allows simple attachment of wheel brushes to CNC machines. No hassle coupling is accomplished by placing the adapter plates on both sides of the wheel brush and securing the device with a bolt to the shell mill holder. Set screws prevent the brush from rotating.Part Number - 35930Face Width - DoubleBrush Inside Diameter (ID) - 5-1/4 in.Pilot - 1-1/4 in.

Additional Information

Abrasive nylon wheel brushes work best at speeds allowing fairly deep penetration of the work piece into the brush filaments. Faster speeds do not typically work as well as slower speeds, since the maximum RPM listed on the brush is not the optimum working speed. A good rule of thumb is to stay below 2,500 SFPM in dry applications and 3,500 SFPM with coolant. When operating multiple wheel brushes on a common shaft, multiply the HP requirements listed above times the number of brushes in use.Penetration (Point of Contact)The abrasive action occurs when the sides of the brush filament slides across the part surface or edge of the part. When the correct balance between speed (RPM), penetration, dwell time and abrasive grit size are achieved, then optimum life and cut can be obtained.Recommended penetration rates for abrasive nylon wheel brushes are maximized up to 10% of trim length. This will allow long brush life with aggressive abrasive action.Considerations when Selecting Filament for a Tanis® Abrasive Nylon BrushGrit Size120 grit is our recommended starting point for most applications. From there you can move either down or up in grit size, for a more aggressive cutting action or more of a polishing action. The chart on page 73 shows our abrasive nylon filament/grit size options.Trim Length and Brush DensityA brush with a short trim length is rigid and used for high speed cutting. Longer trim lengths are more flexible and used for conforming to irregular surfaces. Likewise, a brush with a lower fill density has greater flexibility and ability to conform, as well as increased resiliency. High fill density brushes are used for deburring and when high speed cutting is required.

Applications

Machine Part DeburringTurbine Blade Surface FinishingLight Duty Cleaning/FinishingEdge RadiusingImproving Surface FinishPost Coat Polish of Flutes on Carbide DrillsHone Drill Point Lip Edge on Carbide Drills

Note

Additional diameters and grits available upon request.

Specifications Arbor Hole Size

5-1/4 in

Specifications Brush Diameter

14 in

Specifications Dry Application Starting Speed

800 to 900 rpm

Specifications Face Width

1 in

Specifications Filament

CeramiX®

Specifications Filament Diameter

0.028 in

Specifications Material

Nylon

Specifications Maximum Speed

1800 rpm

Specifications Recommended Motor Size Based On A 1 Inch In Brush

1 hp

Specifications Size

120 grit

Specifications Trim Length

3-1/2 in

Surface Speed Surface Speed Peripheral Speed In Feet Per Minute

900 rpm | 1150 rpm | 1200 rpm | 1500 rpm | 1750 rpm | 2000 rpm | 2400 rpm | 2800 rpm | 3000 rpm | 3200 rpm | 3450 rpm | 3750 rpm | 4000 rpm | 4500 rpm | 5000 rpm | 5400 rpm | 6000 rpm

Troubleshooting Abrasive Nylon Brushes

Brush too aggressiveReduce filament diameter and/or grit sizeReduce surface speed by reducing RPMIncrease trim length and decrease fill densityIncrease feed rateUse a smaller diameter brushBrush not aggressive enoughIncrease filament density and/or grit sizeIncrease surface speed by increasing RPMDecrease trim lengthReduce feed rateUse a larger diameter brushBrush not conforming enough to partIncrease trim lengthReduce filament densityUse a smaller diameter brushReduce surface speed by reducing RPMReduce feed rateFinal finish too roughIncrease surface speed by increasing RPMUse a larger diameter brushUse a finer abrasive filamentUse a coolant or cutting oilUse a buffing compoundFinal finish too smoothReduce surface speed by reducing RPMUse a smaller diameter brushIncrease filament density and/or grit sizeFilament smearing/meltingReduce surface speed by reducing RPMDecrease brush diameterUse a coolant or lubricantMore action needed on edges parallel to brush axisReduce surface speed by reducing RPMReduce feed rateKeep longer brush contact on problem areaMore action needed on edges perpendicular to brush axisReduce surface speed by reducing RPMIncrease feed rateOscillate brush on problem areaBrush action not uniform enoughIncrease trim lengthReduce filament densityUse automated equipment for brush motionShort brush lifeIncrease filament densityReduce pressure/depth of interference