CP Disposable Media Filter Capsules for Critical Processes

CP Disposable Media Filter Capsules for Critical Processes

SKU:PLE-e861c7

Engineered for cost-effective filtration in small flow processes with quality assurance for food, electronic, and pharmaceutical applications.

Regular price

$39.99

Regular price

Sale price

$39.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The CP Disposable Media Filter Capsules by Critical Process are engineered for cost-effective filtration, specifically designed for small flow and encapsulated disposable cartridge needs. Available in various pleated and depth medias, these capsules come in four grades tailored for general, food/beverage, electronic, and pharmaceutical applications. With a focus on quality, traceability, and validation, each capsule is constructed to maximize filter media utilization while reducing filtration costs and minimizing the necessity for expensive metallic housings. Perfect for liquid and gas applications, each capsule comes with a Certificate of Quality Assurance for food, electronic, and pharmaceutical grades.

Product Specifications

Construction Materials Filtration Media

Polypropylene 85%

Construction Materials Filtration Media Support Material

Polypropylene

Construction Materials Grade

Electronic

Construction Materials Housing

Polypropylene

Construction Materials Note

All materials of construction are FDA accepted. Final assemblies have been validated to pass USP class 6 Toxicology extractable tests, oxidizable substances for plastics, endotoxin level and other quality tests.

Construction Materials Sealing Method

Heat - Fused

Construction Materials Support Components Material

Polypropylene

Filtration Media 0

Flow Rate Polypropylene - MBGDMB Melt blown capsules are manufactured by a continuous spun bonding technology that assures a consistent product. 100% all polypropylene construction gives wide chemical compatibility and extremely low extractables. These capsules offer exceptional value in both removal efficiency and dirt holding capacity where protection of more expensive membrane filters is important.

Flow Rate 0

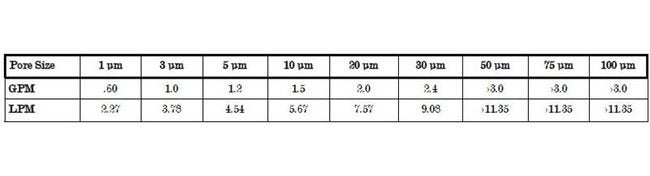

See the Flow Rate table in more image which represents typical water flow at a one psi (69 mbar) pressure differential across a single 2 inch capsule 1.0 ft2 (5.08 cm) of media with 1/2 inch FNPT ports. The test fluid is water at ambient temperature. Higher pressure drops is acceptable, but as flows increase the pressure drop of the housing becomes more apparent.

Maximum Operating Parameters Forward Differential Pressure At 20

50 psi | 3.4 bar

Maximum Operating Parameters Gases Operational Pressure At 20c

60 psi | 4.1 bar

Maximum Operating Parameters Liquid Operational Pressure At 20c

80 psi | 5.5 bar

Maximum Operating Parameters Operating Temperature At 30 Psi 14

110 ºF | 43 ºC

Maximum Operating Parameters Recommended Change Out Pressure

20 psid | 2.4 bar

Maximum Operating Parameters Reverse Differential Pressure At 20

40 psi | 2.7 bar

Pore Size Removal Ratings

0.03 to 100 µ

Quality Standards 0

Our goal is to ensure our customers the greatest possible value for their filtration dollar. We achieve both low cost manufacture and high quality by employing state of the art manufacturing equipment. This computer controlled equipment is highly automated, reducing hand operations that compromise quality. Each operation including assembly, testing, cleaning, drying and packaging is done in appropriately rated clean rooms. Critical Process Filtration manages an ISO 9000 facility that produces validated products to rigorous standards. Manufacturing is controlled using sophisticated MRP software that is networked to work stations in manufacturing centers and inspection points. During the manufacturing and inspection processes, data is collected âreal timeâ from machinery and measuring instruments. This allows variable and attribute data to be quickly and easily analyzed to facilitate constant improvements in both quality and cost.

Sanitization Sterilization Autoclave

250ºF (121ºC), 30 min, multiple cycles

Sanitization Sterilization Chemical Sanitization

Industry standard concentrations of hydrogen peroxide, paracetic acid, sodium hypochlorite and other selected chemicals. Sanitization protocols designed to extend the useful life of CP capsules are available from Critical Process Filtration, Inc.®.

Sanitization Sterilization Filtered Hot Water

194 ºF | 90 ºC

Sanitization Sterilization Inlet Outlet Options

1/2" Female NPT | 1/2" Male NPT | 1/4 Male NPT | 1/4" Female NPT | 3/8" Female NPT | Hose Barb | Sanitary

Sanitization Sterilization Pre Sterilized

Not Sterilized | Pre- Sterilized

Sanitization Sterilization Vent Drain

Standard with Luer- Lok¨ ports and caps

Specifications Capsule Length

2 in | 5 in | 10 in | 23 in | 30 in

Specifications Filter Mediamembrane

Polypropylene GDMB

Specifications Grade Definition

Designed to meet the special needs of the electronics and high purity chemical industries. To minimize extractables, each cartridge module is pulse, power flushed until the rinse effluent reaches 17+ megohm-cm and less than 3 ppb TOC. Each cartridge module is also individually tested.

Specifications Micron Rating

40.0 µ

Total Performance 0

Critical Process Filtration, Inc.® is a vertically integrated supplier of filtration products and services to industries in which filtration is considered to be a critical part of the manufacturing process. We manufacture a complete line of products to help you achieve all your filtration requirements from a single source.

Usp Biosafety 0

The materials used to construct the membrane capsule filters are non-toxic and meet the requirements for the MEM Elution Cytotoxicity Test and USP24 Plastic Class V1 121ºC Test.