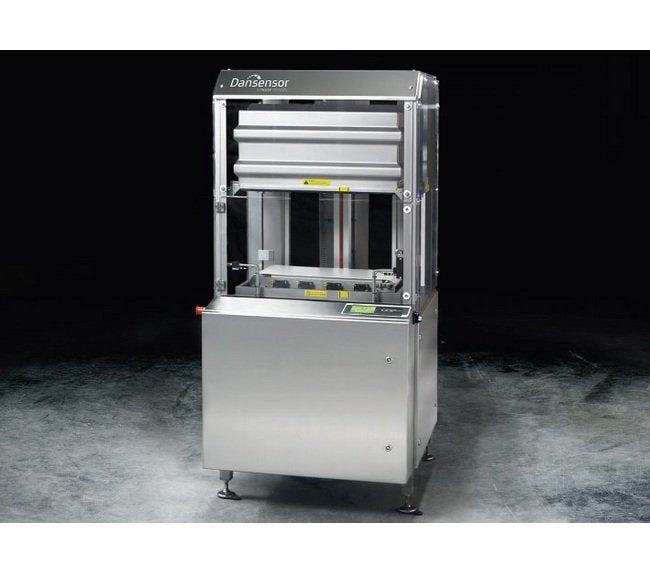

Dansensor LeakMatic II In-line Leak Tester with Packfix - 245mm Max Height

Dansensor LeakMatic II In-line Leak Tester with Packfix - 245mm Max Height

SKU:PRO-4e4e53

Ensure seal integrity with the Dansensor LeakMatic II - precise, automated leak testing for MAP packages. Compliant with CE standards.

Regular price

$18,999.00

Regular price

Sale price

$18,999.00

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Dansensor LeakMatic II ensures seal integrity of Modified Atmosphere Packages (MAP) through precise non-destructive testing. With features like optical sensors, data logging, and automated testing, it guarantees product quality while reducing costs. Benefits include fewer returns, minimal claims, and an enhanced brand image. This product complies with European Conformity (CE) standards.

Product Specifications

Additional Information Additional Information

Designed to meet the growing demand for fresher foods, the Dansensor® LeakMatic II can be integrated right into your packaging line - right after product boxing. The system ensures seal integrity of entire boxes of MAP products at a speed of up to 4 cycles per minute.Ready to move up to efficient, continuous in-line leak testing? Can you afford not to?

Benefits Benefits

Less product returns.Less claims.Safer brand image.

Features Features

Optical sensor.No heating time.Data logging of measurement data.Fully automated non-destructive testing.Easy operation via touch screen.3-year CO2 sensor warranty.

How Does It Work How Does It Work

An individual test program is created for each product to be tested, ensuring that the right test parameters are set for each product.In operational mode the Dansensor® LeakMatic II will automatically signal the feeding conveyor belt when ready for a new test. Operation is entirely automatic once the product program has been selected.During the test a user-defined vacuum is drawn causing a pressure difference between the packages and the chamber - in turn causing CO2 to leak into the chamber. The full test cycle takes 12-15 seconds depending on the product.If a leak is detected, a signal is sent to a package rejection unit and the package is automatically rejected.

Note Note

Specifications subject to change without notice. Further specifications are available in the User Guide.

Specifications Alternating Current Ac Voltage

400 V

Specifications Approximate Weight

450 kg

Specifications Cabinet Depth

1050 mm

Specifications Cabinet Height

1825 mm

Specifications Cabinet Width

880 mm

Specifications Compliances

European Conformity (CE)

Specifications Connections

2 x RS232 for Printer | PC Connection

Specifications Maximum Depth Without Packfix

400 mm

Specifications Maximum Depth With Packfix

300 mm

Specifications Maximum Height Without Packfix

260 mm

Specifications Maximum Height With Packfix

245 mm

Specifications Maximum Width Without Packfix

610 mm

Specifications Maximum Width With Packfix

610 mm

Specifications Note For Start Up Time

After standby: 20 seconds.

Specifications Notice

The LeakMatic is delivered without safety shielding, conveyors and rejection unit.

Specifications Number Of Product Set Ups

16

Specifications Package Sizes

Medium

Specifications Package Types

Flexible, non-flexible packages. Individual packages or complete shipping crates

Specifications Relay Outputs

All relay outputs: Max 48V/1A, "system ready", "ready to test product", "test OK", "leak"

Specifications Sensor Type

Optical Sensor

Specifications Start Up Time After Power On

1 min

Specifications Test Pressure

Down to 300 mbar absolute

Specifications Test Speed

Up to 4 cycles per minute