DUALSCOPE® H FMP150 Coating Thickness Measuring Instrument

DUALSCOPE® H FMP150 Coating Thickness Measuring Instrument

SKU:DUA-2ba8b6

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The most powerful and user-friendly solution for measuring coating thicknessThe FMP100 instrument rises to the challenge of sophisticated and ever-changing measurement applications. It can be used for quality control, in continuous production, for incoming inspections or in the lab, on random samples or entire series. Extensive software functions also make it very well suited for statistical monitoring of processes. Regardless of purpose - whether used in automotive, for electroplating or anodizing, measuring heavy duty anticorrosive layers or the finest of coatings - this flexible instruments always meets the highest standards for precision and trueness.

Product Specifications

Additional Information

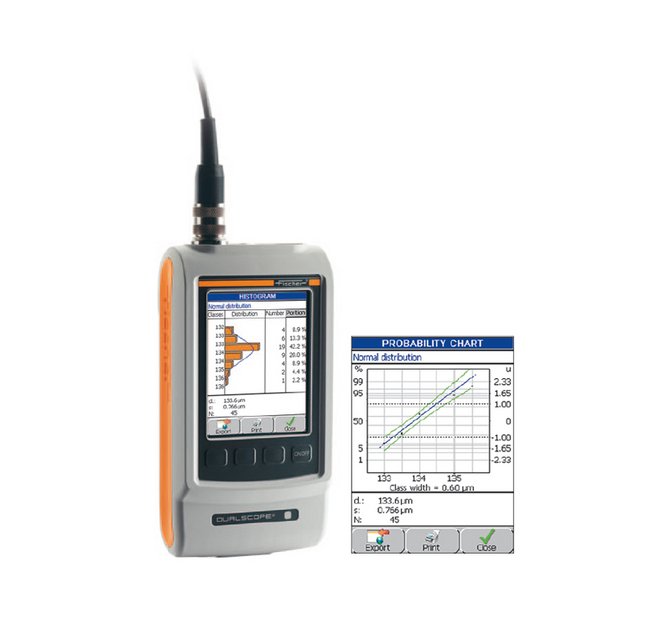

Evaluation options available for the DUALSCOPE® FMP100 instrument include block and final results, histogram, sum frequency, FDD® (Factory Diagnosis Diagram) and matrix evaluation. This allows the measured values to be evaluated according to the user's requirements. The various graphical representations provide a clear overview of the measured test series, facilitating the comparison of individual measurement data or groups thereof. Production processes can be evaluated in one glance and differences between shipments can be pinpointed quickly during incoming inspection.

Data Evaluation

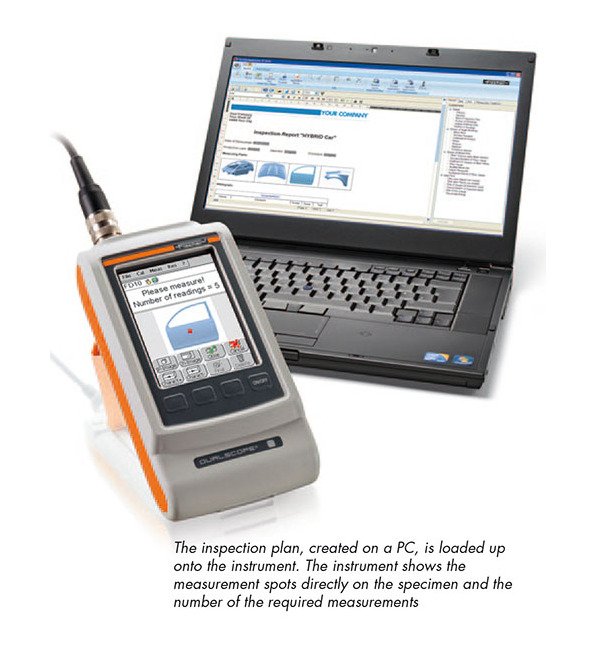

Data Evaluation with the optional PC software Fischer DataCenterFischer DataCenter Software (including shipment)The PC software Fischer DataCenter can be used to transfer measurement data via USB to a PC, where they can be managed and archived. In addition, the measurement data can be analyzed on the PC using versatile evaluation and statistical functions such as histogram, sum frequency, etc. Various chart and table presentation options are available for this purpose.The DataCenter software allows for the design and creation of individual reports using one’s own logos, images and graphics. Using the drag and drop function, it is possible to integrate measurement data, statistical data and graphs, as well as to create report templates based on scanned forms.Optional PC software Fischer DataCenter IP and IPMulti (optional accessory)With the optionally available Fischer DataCenter IP and IP-Multi software, inspection plans can be created on a PC and loaded onto one (IP) or many (IP-Multi) instruments. The operator is then guided step-by-step through the measurement sequence of the inspection plan, assisted by stored images, sketches and technical drawings. For instance, the measurement spots can be shown directly on the specimens. Freely definable selection and entry fields are available for querying, for example, serial or order numbers during inspection plan processing.Attribute lists can also be stored to facilitate the user's entries. Once data acquisition is complete, the data are returned to the PC where they can be evaluated thoroughly and easily, thereby readying the instrument for new measurements.When directly connected to the PC software, the classic measurement device is thus transformed into a mobile data terminal that ensures reliable and convenient user guidance as well as correct and dependable acquisition of complex data.

Evaluation And Statistical Functions

Display of important statistical characteristics such as mean value, standard deviation, min, max, and rangeStatistics of the most important characteristics displayed in block and final results, analysis of variance (ANOVA) valuesGraphical representation as histogram or sum frequency chartInput option for process tolerance limits and calculation of the associated process capability indices cp and cpkFactory Diagnosis Diagram (FDD®) for visualizing process qualityFischer's patented Factory Diagnosis Diagram (FDD®) offers the user a means of visual evaluation by providing a compact overview of the process. An easy-to-interpret diagram provides a distribution graph of production parameters, such as coating thickness. The use of color enables the user to quickly identify areas for optimizing production processes without having to run separate statistical calculations.Print form generationThe FMP100 instrument allows the generation of simple print forms using drag and drop. Via USB, these print forms can then be printed directly from the instrument or transferred to a PC as pdf files. In addition, the Fischer DataCenter provides a convenient software solution for creating individual test reports on a PC.

Features

The portable DUALSCOPE® FMP100 instrument is the perfect solution for professional quality assurance. Unique on the market, this powerful hand-held device for measuring coating thickness is equipped with the following outstanding features:Windows™ CE operating system with graphical user interface and a user-definable file and folder structureHigh-resolution touchscreen with virtual keypad that can be operated using a stylus or fingerLarge memory for several thousand measuring applications with different calibrationsExtensive evaluation and statistics functions with supporting graphical presentation optionsWide selection of high-precision probes including many specialized probes for even the most sophisticated measurement applicationsWith the optionally available inspection plan management software, Fischer DataCenter IP, this professional measurement instrument turns into multi-functional data terminal, opening up a whole new dimension in metrology. With the help of visually-aided operator guidance, individual inspection plans created on a PC can be executed step-by-step on the instrument - and the results evaluated conveniently at the PC.

Instrument Features

Windows™ CE operating system with large touchscreen displayIndividually customizable user interfaceVery simple calibration via operator guidanceClear management of measuring applications through user-definable file and folder structureMemory adequate for thousands of measuring applications and several thousand readingsUSB communication and printer portCan be set to various European and Asian languagesVarious display screens for measurement acquisition, e.g. with concurrent "original value chart" for immediate process visualization

Measurement Acquisition

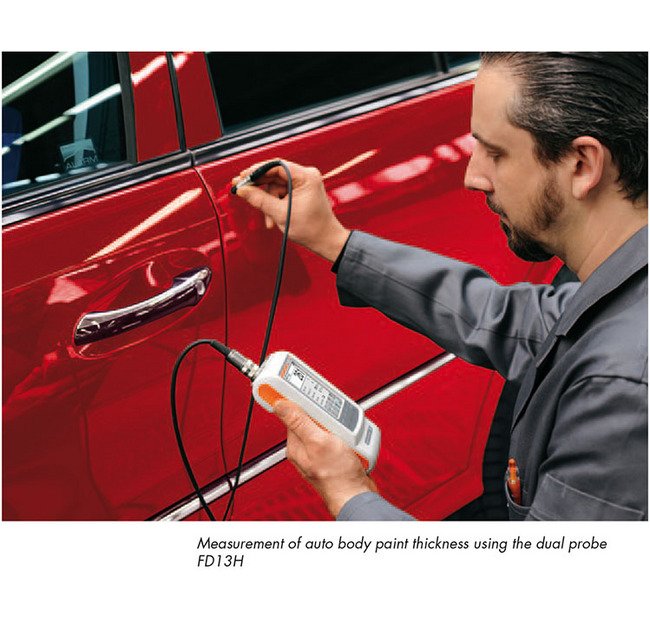

Automatic probe and substrate material recognitionindividual measurement acquisitionAveraging of measurement data: Only the mean value of multiple readings is storedMeasurement acquisition via surface area measurement: Individual readings are captured continually until the probe is lifted, at which point a mean value is generatedMeasurement with "tracking display" for continuous surface samplingOutlier rejection function for the automatic elimination of erroneous measurementsMatrix measurement mode for interrelated multipoint measurementsAdditional applications are provided by the DUALSCOPE® H FMP150. Compared to the FMP100, the FMP150 can also measure with a third method, the magnetic method. This enables further measurement options:Thick metal or protection coatings on steel or ironNickel coatings on nonferrous heavy metals or insulation materials.

Specifications Intended Application

Coating Thickness