Dymax 9801 Camera Module Adhesive

Dymax 9801 Camera Module Adhesive

High-performance camera module adhesive for rapid UV/Visible or LED light curing with heat-cure capability and superior adhesion properties.

Regular price

$39.99

Regular price

Sale price

$39.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

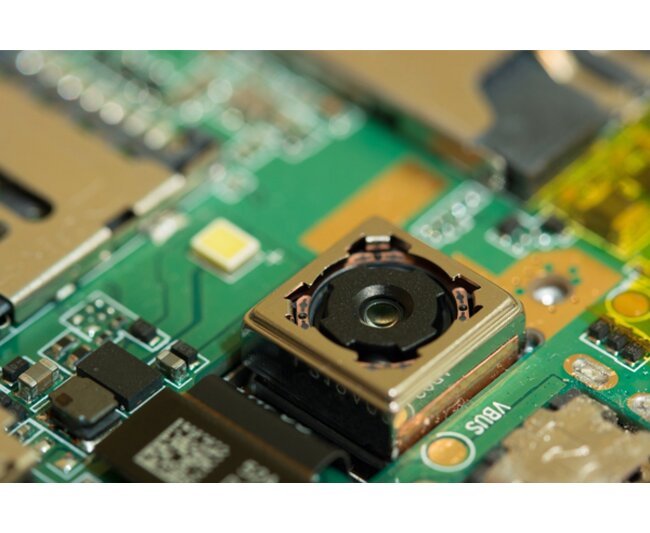

The Dymax 9801 Camera Module Adhesive is a high-performance solution designed for rapid curing with UV/Visible or LED light, featuring secondary heat-cure capability for shadow areas. Its low shrinkage, moisture- and thermal-cycle resistance make it ideal for various camera module applications in ADAS and LiDAR assembly. Meeting ASTM E595 Outgassing standards, this adhesive offers low CTE, high Tg, very low volumetric shrinkage, and superior adhesion properties, ensuring reliable bonding on substrates like PPS, FR-4, LCP, PCB, CAP, PS, and glass. With fast curing, moisture resistance, low temperature heat cure, and cold storage capabilities, the Dymax 9801 is a top choice for active alignment applications.

Product Specifications

Additional Information Additional Information

Low Shrinkage Camera Module Adhesive with LED and Heat-Cure CapabilityDymax® 9801 is a LED or UV/Visible light-curable material with superior adhesion properties for bonding camera modules, lidar, active alignment applications. The adhesive is moisture and thermal cycle resistant and meets the stringent low-shrinkage requirements introduced for active alignment applications in Advanced Driver Assistance Systems (ADAS). 9801 cures with UV light but also features heat-cure capability for applications where shadowed areas exist. This one-component product bonds rapidly and is recommended for surfaces and substrates including LCP, PCB, PPS, FPC, CAP, PS, FR-4 board, and glass.9801 requires cold storage/cold shipping and should be kept between 1ºC (34ºF) and 5ºC (41ºF) in the original, unopened container.Dymax® materials contain no nonreactive solvents and cure upon exposure to light. Their ability to cure in seconds enables faster processing, greater output, and lower processing costs. When cured with Dymax® UV light curing spot lamps, focused beam lamps, flood lamps, or conveyor systems they deliver optimum speed and performance for maximum efficiency. Dymax® lamps offer the optimum balance of UV and visible light for the fastest, deepest cures.

Features Features

Fast cure with LED or UV/Visible lightLow temperature heat cure (80-85ºC)Moisture resistantThermal cycle resistantSingle componentCold ship/Cold storage at 1-5ºCPasses ASTM E595 Outgassing Testing

Specifications Industry Standards

American Society for Testing and Materials (ASTM) E595

Specifications Nominal Viscosity

60,000 cP

Specifications Recommended Substrates

Cellulose Acetate Propionate (CAP) | Flame Retardant (FR-4) | Glass | Polystyrene (PS)

Specifications Recommended Surfaces

Flexible Printed Circuit (FPC) | Liquid Crystal Polymer (LCP) | Polyphenylene Sulfide (PPS) | Printed Circuit Boards (PCB)

Specifications Uncured Appearance

Off White Opaque to Charcoal Translucent Gel

Specifications Volumetric Shrinkage

1.5 %