Dymax GA-201 UV-Cured Gasket Sealant Adhesive

Dymax GA-201 UV-Cured Gasket Sealant Adhesive

SKU:GAS-cac79e

Dymax GA-201 UV-Cured Gasket Sealant Adhesive - High-performance, moisture-resistant solution for various substrates.

Regular price

$29.99

Regular price

Sale price

$29.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

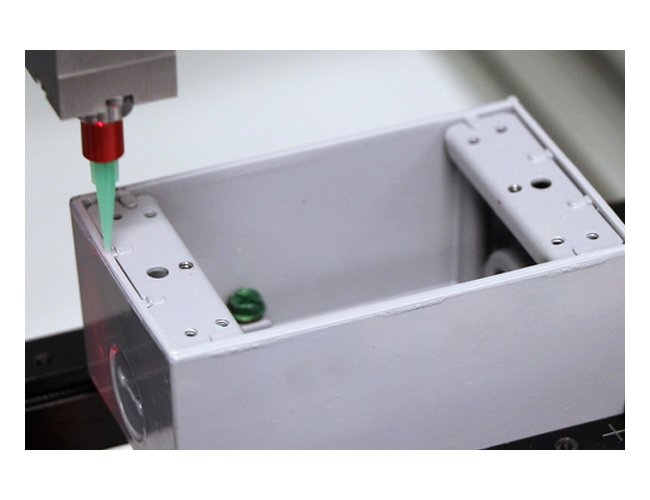

The Dymax GA-201 UV-Cured Gasket Sealant Adhesive is a high-performance solution for creating durable, moisture-resistant seals on a variety of substrates including aluminum, glass, plastics, plated surfaces, and stainless steel. With a nominal viscosity of 65,000 cP and a cured durometer hardness of A35, this adhesive offers excellent adhesion and conforms easily to intricate channels and recesses. It cures tack-free with UV/Visible light, providing a soft and flexible gasket that acts as a barrier against moisture, dust, noise, and other elements. Ideal for automotive, electronics, and energy applications, this product combines speed, efficiency, and reliability in sealant technology.

Product Specifications

Additional Information Additional Information

Tack-Free, Moisture and Chemical Resistant FIP Gasketing ResinDymax® GA-201 form-in-place (FIP)/cure-in-place (CIP) gasketing resin is formulated for sealing plastic, glass and metal enclosures, and plated surfaces for automotive door handle, appliance housing, and critical electronic assembly and device applications which require a soft, tack-free, flexible gasket. This FIP gasket acts as a barrier to moisture to prevent absorption or penetration of air, dust, noise, liquids, gaseous substances, or dirt. It can be dispensed in intricate and complex configurations with the added benefit of curing in-line which allows for increased production speed and reduced inventories. Dymax® materials have no solvents added and cure upon exposure to light. Their ability to cure in seconds enables faster processing, greater output, and lower assembly costs. When cured with Dymax® light-curing spot lamps, focused-beam lamps, or flood lamps, they deliver optimum speed and performance for maximum efficiency. Dymax® lamps offer the ideal balance of UV and visible light for the fastest, deepest cures.This product is in full compliance.

Features Features

Cures with UV/Visible lightMoisture resistantChemical resistantTack-free cureSoft, durable after complete cureConforms to intricate channels and recesses

Specifications Cured Compression Set At 85 Degree Celsius C Temp

26 %

Specifications Cured Durometer Hardness

A35

Specifications Nominal Viscosity

65,000 cP

Specifications Note For Cured Compression Set At 85 Degree Celsi

Compression set is expressed as percentage of deflection per ASTM D395 Method B at 25% deflection. To determine percent recovery, subtract 1/4 of the value from 100%. For example, the recovery is 98.8% with a 5% compression set.

Specifications Recommended Substrates

Aluminum | Glass | Plastics | Plated Surfaces | Stainless Steel (SS)