Eaton-Airflex Single Wide VC Elements Clutch

Eaton-Airflex Single Wide VC Elements Clutch

SKU:CLU-e0ecca

High-performance Eaton-Airflex Single Wide VC Elements Clutch, ideal for industrial machinery. Ventilated Construction for cooling efficiency, easy maintenance.

Regular price

$8,999.99

Regular price

Sale price

$8,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

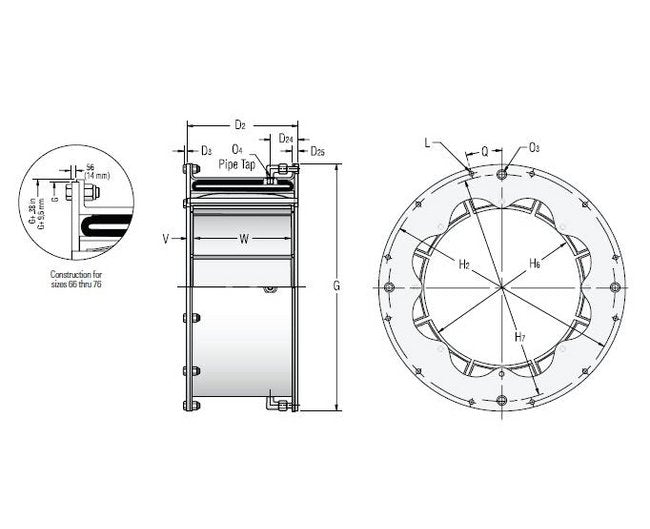

The Eaton-Airflex Single Wide VC Elements Clutch, featuring the 60VC1600 Size and a Torque Rating of 2183000 lb·in, is a high-performance clutch designed for industrial applications. With a Maximum Speed of 520 rpm and a Friction Area of 2800 in², this clutch ensures efficient torque transmission and reliable performance. Its Ventilated Construction allows for optimal cooling, while its Serviceability ensures easy maintenance and part replacement. Ideal for Grinding Mills, Marine Propulsion, and Oil Field Machinery, this clutch is a durable and dependable choice for demanding environments.

Product Specifications

Features 0

Ventilated ConstructionFriction shoe backing plates have large air passages through their entire length. This construction coupled with scalloped side plates allows cooling air to flow through the element. In addition, the large exposed inside diameter assures the coolest possible operation. None of the heat is generated deep in the element's internal parts where it can be trapped. The open construction assures rapid heat dissipation.ServiceabilityThe VC clutch can be dismantled on the shaft to gain access to its component parts. All parts are available as replacement parts.A limited number of element sizes are available in a split configuration. They are used in applications having limited axial access for element maintenance. The following pages give additional descriptive information, selection procedures and common clutch and brake arrangements for the complete VC product line.

General Description 0

VC design and construction is different from the CB and CM elements in that the torque is transmitted by torque bars rather than the sidewalls of the actuating tube. The loose actuating tube is contained within a housing formed by a rim and two side plates. and is replaceable. The torque bars, which are held in position by the side plates, pass through cavities in the backing plates of the friction shoes. Pressurizing the actuating tube forces the friction shoes to engage around a cylindrical drum. Leaf springs in the torque bar cavities of the backing plates retract the friction shoes when the actuating tube pressure is released. Element torque capacity is dependent upon the applied pressure and rotating speed. Catalog ratings are given at 75 psi (5.2 bar) and zero rpm. Maximum recommended pressure is 125 psi (8.6 bar). Adjustment for pressure and speed is explained under Selection Procedure.VC elements are available in 24 sizes which are identified by the drum diameter in inches on which they constrict and the width in inches of its friction lining. For a given drum diameter it is possible to have two different lining widths. For this reason, the elements are grouped by lining width into a narrow series and a wide series. As an example, the narrow series 20VC600 and the wide series 20VC1000 both constrict on a 20 inch diameter drum. But, the narrow unit has a lining width of 6 inches, and the wide unit has a lining width of 10 inches. The smallest VC element will constrict on a 11.5 inch (292 mm) diameter drum and the largest on a 76 inch (1930 mm) diameter drum.Two elements of a narrow series can be bolted together to form a dual element having twice the torque capacity of a single element. With the exception of the 14VC1000 element, the wide series elements can also be dualed. The large drum hub diameter and small drum diameter restricts the radial space available for mechanically connecting the drums to the hub and makes dualing the 14VC1000 elements impractical.The VC design offers the following features in addition to the constricting features described earlier in this section.

Note 0

Part Number refers to basic part number only. When ordering, the number of air inlets and type of connection must be specified.

Specifications Actuation

Air Applied

Specifications Air Tube Cavity

2350 in³ | 38.5 dm³

Specifications Angle Q

5.00 º

Specifications Centrifugal Loss Cs

10.01 E-06 bar/rpm2 | 145 E-06 psi/rpm2

Specifications Dimension D2

18.50 in | 470 mm

Specifications Dimension D24

9.25 in | 235 mm

Specifications Dimension D25

1.38 in | 35 mm

Specifications Dimension D3

0.61 in | 15 mm

Specifications Dimension G

77.000 in | 1955.8 mm

Specifications Dimension H2

75.000 in | 1905 mm

Specifications Dimension H6

60.43 in | 1535 mm

Specifications Dimension H7

74.25 in | 1886 mm

Specifications Dimension J

852.3 kg·m²

Specifications Dimension L Diameter

1.000 in | 25.4 mm

Specifications Dimension O3

0.88 in | 22 mm

Specifications Dimension V

1.25 in | 32 mm

Specifications Friction Area

2800 in² | 18060 cm²

Specifications Friction Shoe Width W

16 in | 406 mm

Specifications Manufacturer

Eaton-Airflex

Specifications Maximum Speed

520 rpm

Specifications Minimum Drum Diameter

59.75 in | 1518 mm

Specifications New Friction

0.66 in | 17 mm

Specifications Number Of Hole L

36

Specifications O4 Number

4

Specifications Size

60VC1600

Specifications Size O4

1-11 1/2 NPT

Specifications Tolerance For L

+0.005/-0.000 in | +0.13/-0.00 mm

Specifications Tolerance For Sizes G

+0.000/-0.010 in | +0.00/-0.25 mm

Specifications Torque Rating 75 Psi55 Bar

2183000 lb·in | 246645 Nm

Specifications Weight

2374 lb | 1077 kg

Specifications Wk2

20532 lb·ft²

Specifications Worn Lining Thickness

0.30 in | 8 mm

Specifications W Number

20

Where Used 0

Grinding Mills Marine Propulsion Metal Forming MachineryOil Field Machinery