EXAIR 1006SS Back Blow Air Nozzle

EXAIR 1006SS Back Blow Air Nozzle

SKU:AIR-791961

Efficiently clean pipes with the EXAIR 1006SS Back Blow Air Nozzle. Amplified airflow for safety & efficiency.

Regular price

$89.99

Regular price

Sale price

$89.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The EXAIR 1006SS Back Blow Air Nozzle is specifically engineered for efficient cleaning inside pipes, tubes, hoses, or channels. Featuring a 360° airflow through an array of holes, this stainless steel nozzle effectively removes coolant, chips, or debris without the risk of creating safety hazards by directing the airflow back towards the operator. With a Coanda effect that amplifies compressed air flow, this nozzle ensures high volume, high velocity air blasts at minimal consumption, improving production, safety, and overall efficiency. Meeting OSHA noise and pressure requirements, this back blow air nozzle offers compact design, reduced compressed air costs, and enhanced chip removal capabilities.

Product Specifications

Specifications Advantages

10 dBA Average Noise Reduction | Compact | Conserve Compressed Air | Improved Blowoff Performance | Improved Production | Improved Safety | Meets OSHA Noise Level Requirements | Meets OSHA Pressure Requirements | Reduced Compressed Air Cost

Specifications Air Consumption

22 SCFM | 622 SLPM

Specifications Applications

Air Assist | Chip Removal | Fiber Conveying | Liquid Blowoff | Material Conveying | Part Cleaning | Part Cooling | Part Drying | Part Ejection

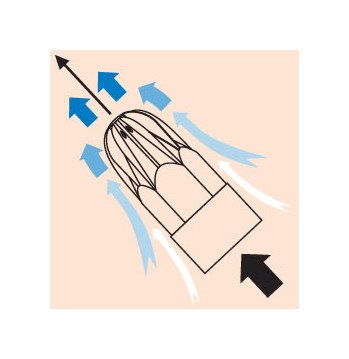

Specifications How Air Nozzles Work

Air Nozzles use the Coanda effect to amplify compressed air flow up to 25 times or more. As illustrated on the right, compressed air (black arrows) is ejected through a series of nozzles on the outer perimeter. As the air travels along the outer wall of the nozzle, surrounding air (blue arrows) is entrained into the stream. The airstream that results is a high volume, high velocity blast of air at minimal consumption. The air is always ejected so it can vent safely, well below OSHA dead end pressure requirements, should the nozzle end be blocked.

Specifications Inlet

1/4 FNPT

Specifications Material

316 Stainless Steel

Specifications Pressure

80 psig | 5.5 bar

Specifications Selecting The Right Air Nozzle

EXAIR manufactures a wide selection of Air Nozzles and Jets, which are divided into two groups. The first group includes Air Nozzles and Jets that deliver force up to 22 ounces (624 grams) and are suitable for most applications. The second group includes Air Nozzles that produce high force up to 23 lbs (10.43 kg) where additional reach and force are required.Type 303 Stainless Steel - high temperatures and corrosive environments. Max temp 800°F (426°C)Type 316 Stainless Steel - high temperatures, corrosive environments, and mechanical wear. Max temp 1000°F (538°C)Brass - general purpose applications. Max temp 400°F (204°C)Zinc Aluminum Alloy - general purpose applications. Max temp 250°F (121°C)PEEK - replaces metals in harsh environments. Offers chemical resistance, non-marring. Max temp 320°F (160°C)

Specifications Sound Level

80 dBA