FISCHERSCOPE® X-RAY 4000 Measuring Systems

FISCHERSCOPE® X-RAY 4000 Measuring Systems

SKU:FIS-299a23

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

With the FISCHERSCOPE® X-RAY 4000 Inline measurement system, Fischer has created a product for continuous measurements in running production lines, whose rugged design specifically meets the tough demands of industrial environments.The X-RAY 4000 measurement systems can be customized for various purposes: detector options include proportional counter tube, silicon PIN and silicon drift detector; the X-ray beam can be oriented from bottom to top, from top to bottom, or horizontally; and, with a second measuring head, simultaneous measurement of the front and back of an object is possible.To allow for measurements at multiple spots perpendicular to the direction of the specimen movement, the measuring head can be very accurately positioned along this axis. Three versions with different travel path lengths are available. Two of these versions also provide for temperature control of the measurement system, making them capable of examining hot surfaces.

Product Specifications

Additional Information

Due to the orientation of the built-in camera's optics along the X-ray beam, which correctly presents the measurement spot's position and size, it is possible to target the relevant measuring points precisely, similar to with bench-top units. And since the travel path of the measuring head runs perpendicular to that of the sample conveyor, it is also possible to inspect multiple point on a given object. By selecting different filters and apertures, the instrument can be quickly adapted to measure several different coatings on the same specimen.As a true inline measurement system, the FISCHERSCOPE® X-RAY 4000 is designed specifically for user friendliness and minimal setup times. For example, converting from one production line to another is simple due to the easily adjustable conveyor guides. Calibration is also automated and therefore quickly carried out.Various data interfaces allow for easy integration of the instruments into quality management systems or controls. The production process can also be monitored directly at the measurement location, alerting operators immediately when control limits are violated, for example.

Characteristics

X-ray tube with W-anode and glass window or micro-focus X-ray tube with W-anode and beryllium window.Proportional counter tube, Peltier-cooled Silicon PIN diode or silicon drift detector as X-ray detectorAperture: 2-x exchangeable, Ø 0.3 mm and 4 mm x 0.12 mmTravel: 230 mm in the standard version (optionally expandable to 620 or 1000 mm)Video camera for optical observation of the measurement location along the axis of the primary X-ray beam. Crosshairs with calibrated scale (ruler) and display of the measurement spot in the still image

Examples From Practical Applications

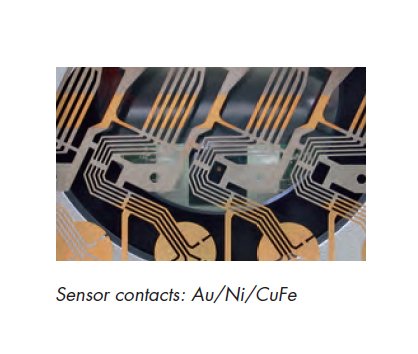

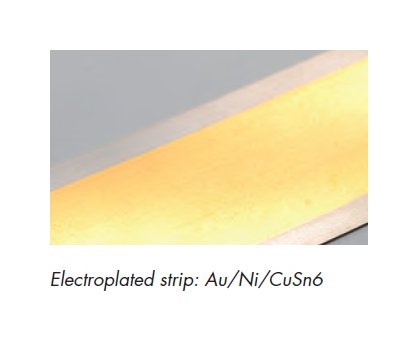

If stamped parts are to be partially gold-coated, the thickness of the gold layer should ideally be inspected during the production process. Doing so can verify a minimum thickness, eliminating the waste of valuable raw materials through coatings that are too thick. The metrological difference between stamped and full strip is compensated by the WinFTM software.

Specifications Aperture

2-x Exchangeable

Specifications Aperture Diameter

0.3 mm

Specifications Maximum Operating Power

50 W

Specifications Maximum Operating Voltage

50 kV

Specifications Measuring Distance

30 mm

Specifications Primary Filter

Fixed or 3-x Exchangeable

Specifications Travel

230 mm in the Standard Version | Optionally Expandable to 620 or 1000 mm

Fields Of Application

Strip electroplating, e.g. contacts, stamped componentsMeasurement on hot-galvanized stripsPhotovoltaic industryMetal coatings on foils and stripsElectronics industry, suppliersProcess monitoring