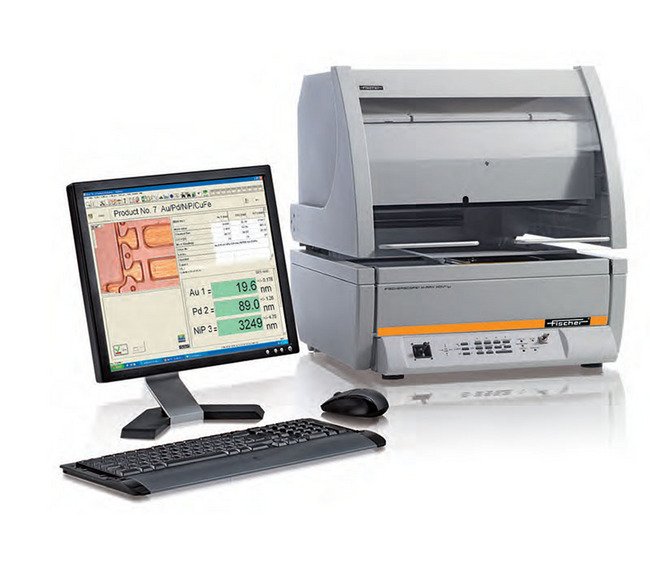

FISCHERSCOPE® X-RAY XDV-µ® Measuring Systems

FISCHERSCOPE® X-RAY XDV-µ® Measuring Systems

SKU:FIS-d8700c

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The FISCHERSCOPE® X-RAY XDV-µ® measurement systems are equipped with a poly-capillary X-ray optics for focusing the X-radiation. This enables both the resolution of very small measurement spots and high excitation intensity. The instruments' large-area silicon drift detectors make them particularly effective for measuring very thin coatings, as well as for trace analysis on small structures or components.In order to create optimal excitation conditions for every measurement, the XDV-µ® systems are supplied with four exchangeable primary filters.With their large and easily accessible measurement chambers, the XDV-µ® instruments are well-suited for measurements on flat, plane objects. For large, flat samples such as PC Boards, the housing has openings on the side (C-slot).

Product Specifications

Additional Information

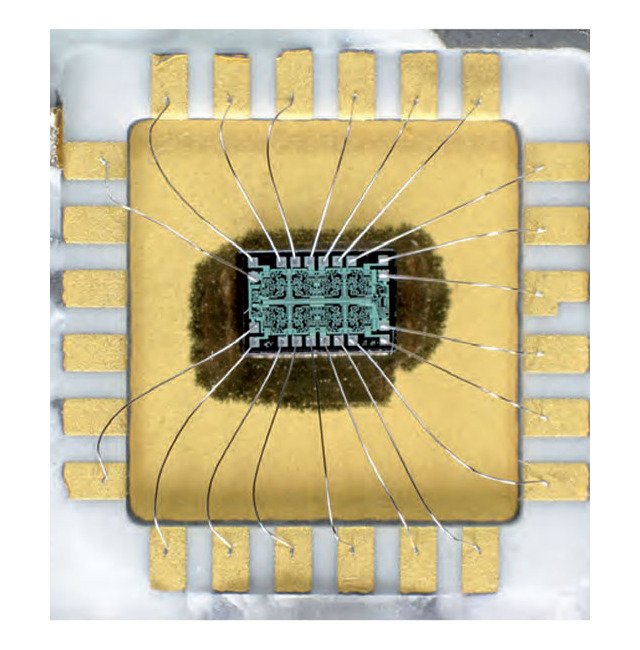

Serial tests or measurements of coating thickness and element distribution are made easy with the fast, programmable XY-stage.User-friendly operation, a wide-opening hood with a large viewing window and control elements located on the front of the device facilitate the day-to-day use of these instruments.Precise positioning of the sample is ensured by a high resolution video optics with three magnification levels, meaning that even the thinnest of wires or very small contact points on semiconductors can be displayed, razor-sharp, with the measurement spot appearing exactly at the target position. A laser pointer acting as a positioning aid further facilitates orientation of the samples.Their performance capabilities and specialization on the smallest structures make the XDV-µ® instruments ideal for research and development, process qualifying, and for laboratories. They are also indispensable in quality assurance, as well as in production monitoring.

Characteristics

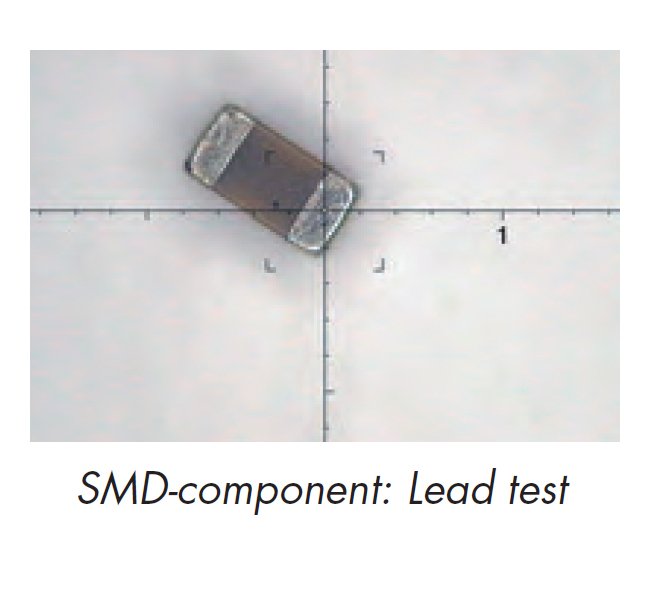

Micro-focus X-ray tube with W-anode and beryllium window, optional Mo-anode.Peltier-cooled silicon drift detector as the X-ray detectorPoly-capillary X-ray optics, measurement spot with about 10 to 40 μm FWHM, also halo free optics availableProgrammable XY-stage with pop-out functionVideo camera for optical monitoring of the measurement location. Crosshairs with calibrated scale (ruler) and display of the measurement spot

Examples From Practical Applications

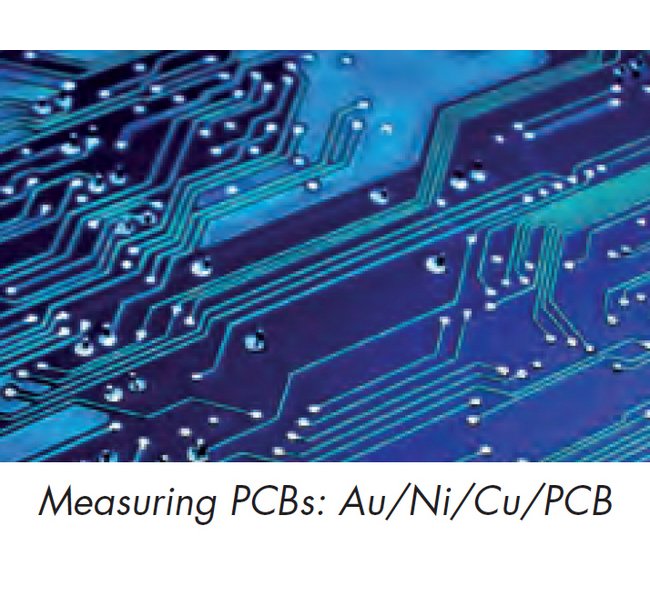

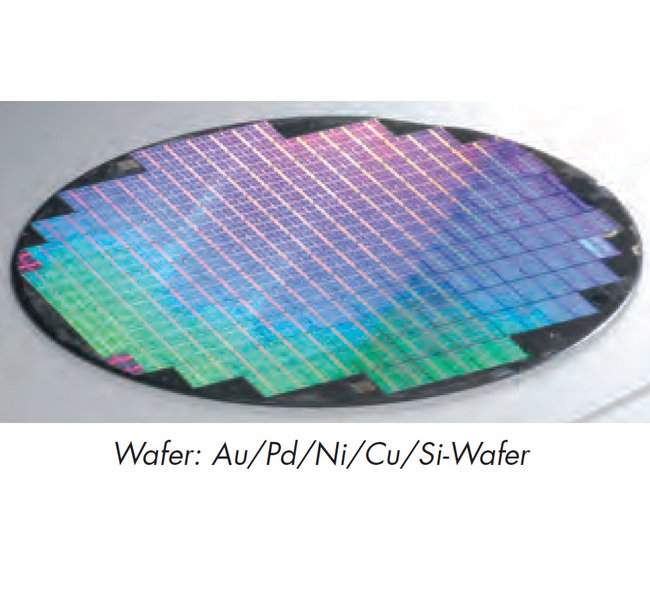

A typical coating system for contact points on PC Boards is Au/Pd/Ni/Cu/PCB, where the structures to be measured are often smaller than 100 μm. Au and Pd coatings typically range in thickness between 10 and 100 nm. With the XDV-µ®, thin gold or palladium coatings can be measured with repeatability precisions of ~0.1 nm or ~0.5 nm, respectively, on measurement spots with 20 µm FWHM.

Specifications Maximum Operating Power

50 W

Specifications Maximum Operating Voltage

50 kV

Specifications Measuring Distance

10 to 40 µm

Specifications Primary Filter

4-x Exchangeable

Fields Of Application

Measurement of coating systems on PC Boards, lead frames and wafersMeasurement of coating systems on small components and thin wiresMaterials analysis on small structures and small componentsEspecially for measuring large and/or flexible PCBs optimized models with extended sample support are availableFor better handling of wafer a wafer chuck is obtainable