Force Sensing Shackle Load Pins RCP/SCP Series

Force Sensing Shackle Load Pins RCP/SCP Series

SKU:LOA-50aea6

Upgrade to precision force sensing with the RCP/SCP Series Load Pins - ideal for accurate direct force measurement in a durable stainless steel design.

Regular price

$349.99

Regular price

Sale price

$349.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

Upgrade your existing Crosby and Skookum shackle pins with our RCP/SCP Series Force Sensing Shackle Load Pins. These load pins offer precision load sensing, rugged stainless steel construction, and easy installation. With measurement ranges from 2,000 to 220,000 lbs, these pins provide accurate direct force measurement for a variety of applications. Featuring internally sealed strain gages and high strength stainless steel material, these pins ensure reliable performance in demanding environments. Perfect for both consumer and institutional buyers looking for top-quality load pins that meet rigorous procurement standards.

Product Specifications

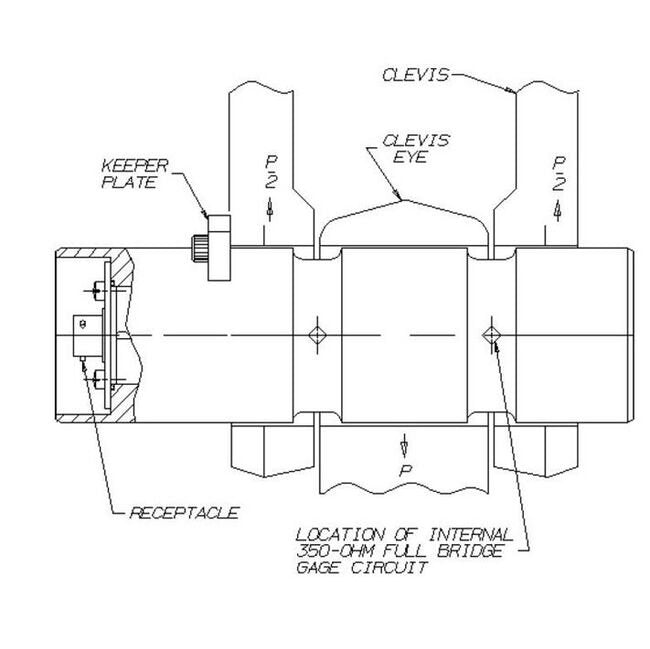

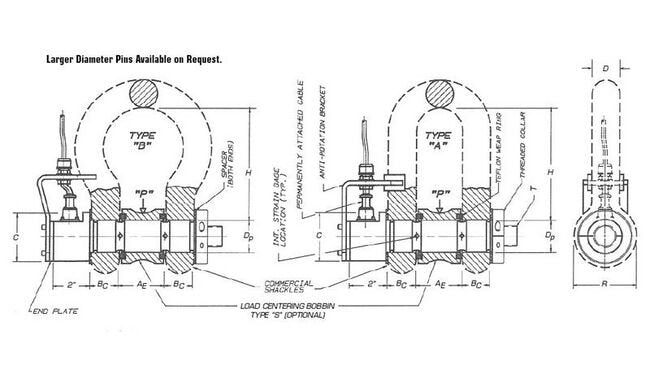

Dimensional Drawing Dimensional Drawing

RCP-SCP Force Sensing Shackle Bolt

Electrical Specifications Cable

#20(26x34) AWG., rubber insulation, shielded, rubber jacket, 4-Conductor (Standard Cable)

Electrical Specifications Excitation

Red

Electrical Specifications Function

Wire Code

Electrical Specifications Signal

Green

Features 0

Precison Load Sensing Rugged Internally Sealed Strain Gages Easy Installation Direct Force Measurement High Strength Stainless Steel

General Information 0

Shackle Load Pins are strain gage transducers developed by Strainsert (U.S. Patent No. 3,695,096). They are manufacured utilizing the internal strain gage process perfected by Strainsert since 1960. They offer precision force measurement by simply replacing existing shackle pins.The pin design is a double-shear arrangement. Typically, force P is applied at the center of the pin while 2 equal opposing forces of P/2 are applied at each end at the shackle ears. Strain gages are sealed inside a small axial hole and are positioned at the 2 shear locations at the interface between the shackle ears and the shackle eye. The strain gages are positioned and oriented with great precision along the neutral plane relative to the specific direction of force.An anti-rotation device is necessary for proper reading and alignment. If a force P is applied to the pin at an angle other than the specified direction, the theoretical bridge output will be offset by a component of the force along the sensitive direction, i.e. P cos X.The four strain gages (two at each shear location) are electrically connected to form a full bridge, the signal from each gage being additive so that the bridge output is proportional to the sum of the forces transmitted by the shear planes of the pin. The circuit typically includes temperature compensation, signal trim (optional), and zero balance resistors terminating in a suitable connector socket or integral cable, and potted with a sealing compound inside the gage hole for enhanced environmental protection.Standard models include detailed calibration data up to 500,000 lbs. Higher capacity calibration data is available at an additional charge. Strainsert factory calibrations are intended to simulate installed conditions, however, it is recommended that an in-place calibration be performed to account for any installation, tolerance, and/or alignment influences affecting sensor measurement.Standard models are typically used in new applications where the designer can develop the specific load pin joint around the standard load pin dimensions, to optimize force measurement performance. In addition, the standard load pin may fit or can be incorporated through the use of bushings or modification of the assembly.

Performance Specs Bridge

Full bridge 350 Ohm (Nominal)

Performance Specs Excitation

12 V AC (Maximum) | 12 V DC (Maximum)

Performance Specs Hysteresis

±0.50% FS (Nominal)

Performance Specs Non Linearity

±0.50% FS (Nominal)

Performance Specs Non Repeatability

±0.15% FS (Nominal)

Performance Specs Output Signal

2-mV/V (Nominal) | 2-mV/V (Standardized Output)

Performance Specs Overload Without Failure

300% (Minimum)

Performance Specs Overload Without Zero Shift

150%

Performance Specs Service Temp Range

to 150 °F

Performance Specs Temp Effects On Output

0.008% load / °F (Nominal)

Performance Specs Temp Effects On Zero

0.005% FS / °F (Nominal)

Performance Specs Zero Balance

±2% FS (Nominal)

Specifications Ae Shackle Opening

1.81 in

Specifications Ae Tolerance

0.13 in

Specifications Bc Width Of Shackle Eard Nominal

1.25 in

Specifications Connector Type

Permanently Attached Cable

Specifications C Clevis Bolt Head Diameter

2.000 in

Specifications Dp Nominal Shackle Bolt Diameter

1.250 in

Specifications H Inside Length Of Anchor Shackle

4.25 in

Specifications H Inside Length Of Chain Shackle

3.56 in

Specifications Load Capacity

22000 lb

Specifications Material

Stainless Steel 17-4, H-1025 (Standard)

Specifications R Outside Diameter Of Shackle Ear Nominal

2.62 in

Specifications Shackle Size

1-1/8 Inch

Specifications Shackle Type

Anchor Shackle | Chain Shackle

Specifications T Thread Size

1-14 UNF