Free Cooling Systems

Free Cooling Systems

SKU:FRE-03f544

N/A

Regular price

$49.99

Regular price

Sale price

$49.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

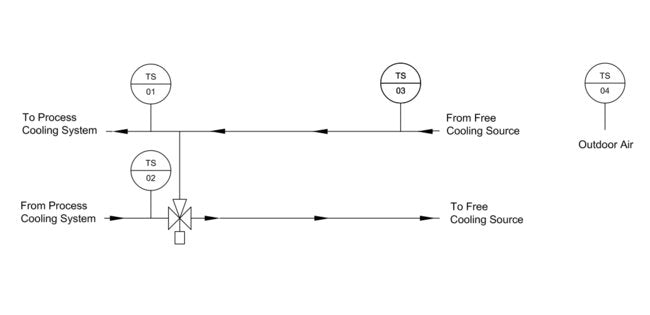

A free cooling system reduces energy use by using a fluid cooler or cooling tower to cool the process fluid in place of a chiller. The free cooling source is commonly a fluid cooler but a cooling tower may be used. The free cooling source may be dedicated to free cooling or could be the primary cooling source with a dual or dynamic set point that changes based on the outdoor air temperature. It can use either a dynamic or static set point and can be isolated from the process fluid circuit with a heat exchanger, or can be in a common fluid circuit with the process fluid.

Product Specifications

Common Source System

In a common source system, the process cooling system and the free cooling system share a common fluid. The common source free cooling system is typically only used when there is a dedicated fluid cooler in line with a chiller, designed to run during cooler weather conditions, where the ambient air is able to provide a portion or all of the process cooling. These systems typically use a glycol solution as the cooling fluid due to prevent freezing in the fluid cooler during winter operation.

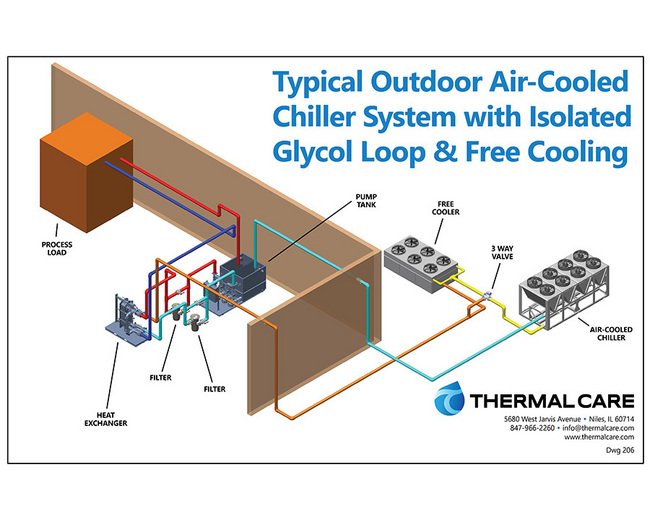

Isolated Source System

In an isolated source system, a heat exchanger isolates the process cooling system from the free cooling system. This allows the use of a glycol solution as the cooling source and/or to protect the process fluid from contamination from the cooling source. In cases where a fluid cooler or adiabatic fluid cooler with a glycol solution is the cooling source, the heat exchanger isolates the process fluid from the glycol solution to allow water to be used in the process loop. In cases where a cooling tower is the cooling source, the heat exchanger provides protection of the process fluid from possible contamination from the cooling tower water.