Gardner Denver 4500 Series Model 812 Positive Displacement Blower with Vacuum Pump

Gardner Denver 4500 Series Model 812 Positive Displacement Blower with Vacuum Pump

SKU:BLO-81e74d

Experience superior industrial performance with the Gardner Denver 4500 Series Model 812 Blower/Vacuum Pump

Regular price

$4,999.99

Regular price

Sale price

$4,999.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Gardner Denver 4500 Series Model 812 Positive Displacement Blower with Vacuum Pump sets the industry standard with over seventy years of expertise in industrial equipment design. This blower/vacuum pump combo offers robust performance, featuring a durable construction, simplified maintenance, and noise reduction technology. With a continuous duty service capability, it meets various industry applications from aquaculture to wastewater treatment. Backed by ISO 9001:2008 quality standards, this product is a reliable choice for institutions seeking top-tier performance and longevity.

Product Specifications

4500 Series Design Features

Rated for continuous duty in all industrial applications.Provides longer life, simplified maintenance and reduced service intervals.Permits higher speeds and performance ratings.

4500 Series Performance Range Delivers 4500 Series Performance R

Continuous duty service.Mechanical seals are available for gas service applications.

4500 Series Performance Range Delivers Discharge Temperatures

Up to 325 ºF

4500 Series Performance Range Delivers Pressure

Up to 15 psig

4500 Series Performance Range Delivers Vacuum

Up to ≥ 16 Hg

Additional Information

The 4500 Series cycleWith every rotation of the blower drive shaft, two lobe impellers turn in opposite directions transferring a constant volume of air or gas from inlet to discharge.

Bearings

Anti-friction bearings are locked against shoulders on both impeller shafts at gear end.These bearings maintain factory-set clearances between head-plates and impellers.Bearings are sized so the drive shaft may be direct or belt driven.

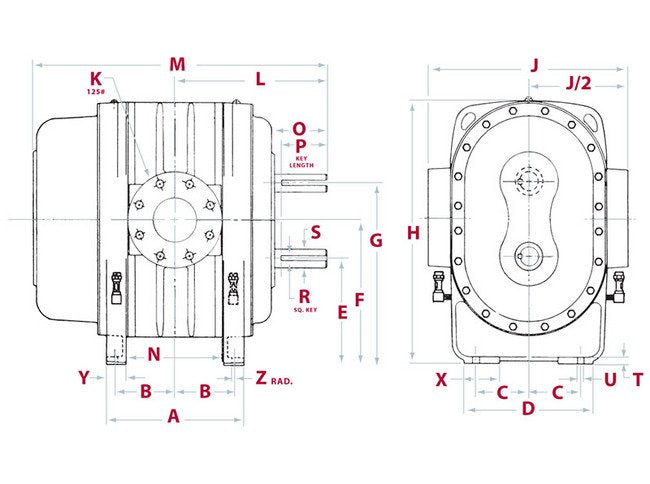

Horizontal Configurations Approximate Weight Horizontal

1050 lb

Horizontal Configurations A Horizontal

18 3/4 in

Horizontal Configurations B Horizontal

8 in

Horizontal Configurations C Horizontal

8 in

Horizontal Configurations D Horizontal

21 1/2 in

Horizontal Configurations E Horizontal

1 1/2 in

Horizontal Configurations F Horizontal

12 1/2 in

Horizontal Configurations G Horizontal

22 in

Horizontal Configurations H Horizontal

23 1/2 in

Horizontal Configurations J2 Horizontal

12 5/8 in

Horizontal Configurations J Horizontal

25 1/4 in

Horizontal Configurations K Horizontal

8 in

Horizontal Configurations L Horizontal

18 1/8 in

Horizontal Configurations M Horizontal

34 in

Horizontal Configurations N Horizontal

12 in

Horizontal Configurations O Horizontal

6 3/4 in

Horizontal Configurations P Horizontal

6 1/2 in

Horizontal Configurations R Horizontal

1/2 in

Horizontal Configurations S Horizontal

1 7/8 in

Horizontal Configurations T Horizontal

1 in

Horizontal Configurations U Horizontal

7/8 in

Horizontal Configurations V Horizontal

4 in

Horizontal Configurations X Horizontal

5 1/4 in

Horizontal Configurations Y Horizontal

3 1/4 in

Horizontal Configurations Z Horizontal

7/16 in

Industryapplications Application For Aquaculture Industry

Aeration

Industryapplications Application For Cement And Lime Industry

Fluidization and Conveying

Industryapplications Application For Chemical Industry

Vacuum Processing and Conveying

Industryapplications Application For Dairy Industry

Automated Milking

Industryapplications Application For Dry Bulk Hauling Industry

Trailer Unloading and Aeration

Industryapplications Application For Environmental Services Indu

Sewer Cleaning and Portable Restroom Services

Industryapplications Application For Power Generation Industry

Fly Ash Conveying and Aeration