Gardner Denver Troubleshooter Oil/Water Separator - 30 gal Filter Capacity

Gardner Denver Troubleshooter Oil/Water Separator - 30 gal Filter Capacity

SKU:AIR-4e880e

Efficiently separate emulsified oils with Gardner Denver's Troubleshooter Oil/Water Separator. Low maintenance, high performance.

Regular price

$2,799.99

Regular price

Sale price

$2,799.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Gardner Denver Troubleshooter Oil/Water Separator with a 30-gallon filter capacity is a cutting-edge solution for effectively separating emulsified compressor condensate, ensuring levels of 15 ppm or less. Featuring a patented delivery system, this separator is designed for low maintenance, automatic operation, and extended filter life. With non-corrosive materials and a non-clogging filter design, it offers effortless maintenance procedures, making it ideal for institutional buyers seeking an efficient and compliant solution.

Product Specifications

Additional Information

Those filters have to be replaced before their capacity is fully used. This is a result of oil binding off the pore area of the carbon where the condensate first comes in contact with the filter. The jelled oil clogs the filter, which then prevents the volume of condensate from properly flowing through the filter. This premature failure of the carbon filters most often results in the system backing up on the floor.Inter-connecting fittings and hoses are supplied for connecting the delivery system to the filter modules.

Benefits And Savings

Troubleshooter, is designed to effectively separate emulsified compressor condensate to levels of 15 ppm or less without premature element failure and backup spillages.Delivery system, (patent pending) has pneumatically operated pump that is used to feed the filter module. The use of the pressure assures the filter will not clog.Increased media's ability, up to four times the amount of oil that standard activated carbon can hold. This is due to the aluminosilicate is coated with hydrophobic compound (patent pending).Improved efficiency, system only requires compressed air to operate the diaphragm pump.Same delivery system is used for each filter module. Expanding air system may only require a larger filter module.

Features

Separates Emulsified OilsLow Maintenance CostsOnly Two Moving PartsFully AutomaticNon-Corrosive MaterialsExtended Filter LifeNon-Clogging Filter DesignEffortless Maintenance Procedures

Note

Not recommended for Food Grade or Silicone based lubricants. All design specifications are subject to change without notice.

Operation

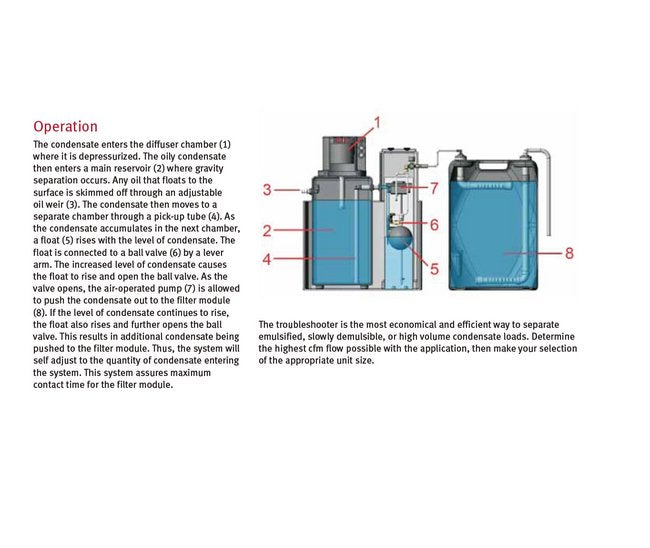

The condensate enters the diffuser (1) chamber where it is depressurized. The oily condensate then enters a main reservoir (2) where gravity separation occurs. Any oil that floats to the surface is skimmed off through an adjustable oil weir (3). The condensate then moves to a separate chamber through a pick-up tube (4). As the condensate accumulates in the next chamber, a float (5) rises with the level of condensate. The float is connected to a ball valve (6) by a lever arm. The increased level of condensate causes the float to rise and open the ball valve. As the valve opens, the air-operated pump (7) is allowed to push the condensate out to the filter module (8). If the level of condensate continues to rise, the float also rises and further opens the ball valve. This results in additional condensate being pushed to the filter module. Thus, the system will self-adjust to the quantity of condensate entering the system. This system assures maximum contact time for the filter module.The troubleshooter is the most economical and efficient way to separate emulsified, slowly demulsible, or high volume condensate loads. Determine the highest cfm flow possible with the application, then make your selection of the appropriate unit size.

Specifications Container Material

Polyethylene

Specifications Delivery Flow

250 to 560 ft³/min

Specifications Depth

19 in

Specifications Filter Capacity

30 gal

Specifications Height

29 in

Specifications Inlet Pipe Size

3/8 in

Specifications Maximum Oil Capacity

12 gal

Specifications Maximum Power

100 hp

Specifications Water Output Pipe Size

2 in

Specifications Weight

200 lb

Specifications Width

19 in

Troubleshooter Filter Modules Container Material Troubleshooter

Polypropylene

Troubleshooter Filter Modules Depth Troubleshooter Filter Module

16 in

Troubleshooter Filter Modules Filter Capacity Troubleshooter Fil

30 gal

Troubleshooter Filter Modules Height Troubleshooter Filter Modul

38 in

Troubleshooter Filter Modules Inlet Size Troubleshooter Filter M

1/2 in

Troubleshooter Filter Modules Inlet Type Troubleshooter Filter M

NPT in

Troubleshooter Filter Modules Maximum Capacity Troubleshooter Fi

0.9 gpm

Troubleshooter Filter Modules Maximum Flow At 20 Psi Troubleshoo

0.35 ft³/min

Troubleshooter Filter Modules Note For Troubleshooter Filter Mod

A Troubleshooter filter module could last 12 months in a Rotary Screw application. However, filter life may be less due to lubricant, compressor type, and maintenance. Reduce cfm ratings by 50% for reciprocating compressors with lubricators.When properly maintained, the troubleshooter will have discharge water containing less than 15 ppm of oil remaining.

Troubleshooter Filter Modules Oil Out Troubleshooter Filter Modu

3/4 in

Troubleshooter Filter Modules Pump Material Troubleshooter Filte

Acetal | Viton

Troubleshooter Filter Modules Troubleshooter Filter Module Part

7037094

Troubleshooter Filter Modules Width Troubleshooter Filter Module

24 in