GO Regulator HPR-2 Electrically Heated Regulator

GO Regulator HPR-2 Electrically Heated Regulator

SKU:GOP-580966

Versatile regulator with exceptional stability and CSA/ATEX approval for reliable performance in industrial applications.

Regular price

$599.99

Regular price

Sale price

$599.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

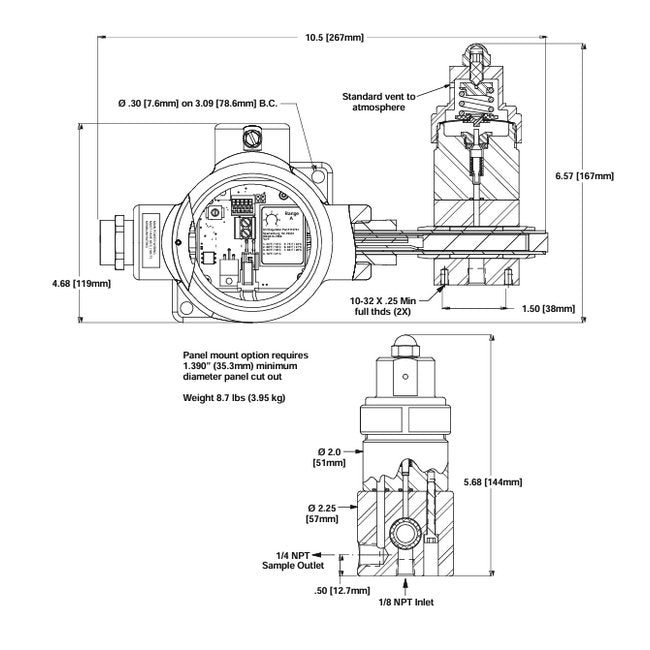

The GO Regulator HPR-2 Electrically Heated Single Stage Vaporizing Regulator is a versatile solution designed to supply heat to samples in instrumentation systems with exceptional outlet pressure stability. With a heater wattage of 100W and a temperature range of 75 to 175 ºF, it features a modular design with a heat exchanger element providing up to 100 square inches of heat transfer area. This regulator is CSA and ATEX approved, ensuring safety and performance in demanding industrial environments.

Product Specifications

Features And Benefits Features And Benefits

Optional HASTELLOY® C and MONEL®Electropolished body with better than 25 Rafinish in diaphragm cavity for an optimal sealing surfaceBubble-tight shutoffModular pressure control and heat exchanger assemblies for easy maintenanceUnique spiral wrapped heat exchange element provides up to 100 square inches of heat transfer area.Optional TCO heating cartridgeINCONEL® diaphragm standard

Note Note

Contact the factory for any additional requirements.Units that will be used for flammable liquid or gas with fire point at 200ºC or below require the TCO Thermistor. It is also recommended to use the 1-PC body option. In addition, Tefzel and PCTFE seats in these units are recommended to use the captured vent cap option which provides for venting to a safe location.

Specifications Body Material

316L Stainless Steel

Specifications Cap Assembly

Tamper-Proof, Standard, Stainless Steel

Specifications Certifications

Canadian Standards Association (CSA) Certification # LR-82566-5 | Certification # TRL03ATEX11001X

Specifications Flow Coefficient Cv

0.06

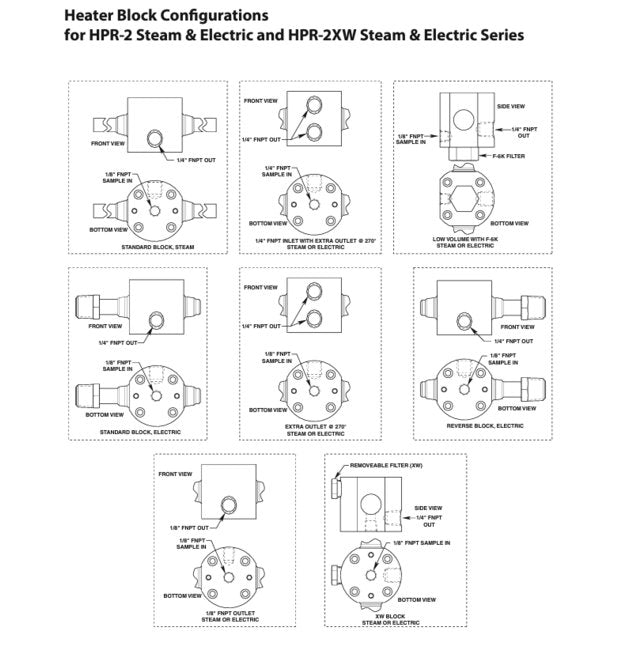

Specifications Heater Block Porting

Extra Outlet Block

Specifications Heater Wattage

100 W

Specifications Options

TCO Thermistor

Specifications Outlet Range

0 to 50 psig

Specifications Port Configuration

One Inlet Port, One Outlet Port

Specifications Seat Material

Tefzel®

Specifications Temperature Rangeheating Type

75 to 175 ºF

Technical Data Inlet Pressure

Up to 6000 psig at 380 ºF (193 ºC)

Technical Data Operating Temperature

0 to 500 ºF | 260 ºC

Applications Applications

Analytical process sample conditioning systems:Petrochemical refineriesChemical production facilitiesPilot plants (chemical & petrochemical)LNG loading and off-loading pointsNatural gas pipeline sampling