Grade 7 HF Series 8-Inch Modular Air Line Filter

Grade 7 HF Series 8-Inch Modular Air Line Filter

SKU:AIR-1f1317

Optimize air quality with Grade 7 8" Modular Air Line Filter. ISO & CAGI compliant for superior performance.

Regular price

$199.99

Regular price

Sale price

$199.99

Unit price

per

Delivery via Maden

Expect your order to arrive on time.

Secure Payments

All orders are processed through a secure, PCI-compliant checkout.

The Grade 7 HF Series 8-Inch Modular Air Line Filter is engineered to deliver quality compressed air, protecting pneumatically operated tools with precision and efficiency. With a flow capacity of 20 scfm, this filter offers solid particulate removal to 1 micron, ensuring superior air quality compliant with ISO and CAGI standards. Featuring a modular housing constructed from aluminum, steel, and zinc, this filter maximizes durability and corrosion resistance. The easy-to-operate design includes an internal automatic drain and a differential pressure gauge for seamless maintenance. Experience optimal air filtration and system efficiency with the Grade 7 HF Series 8-Inch Modular Air Line Filter.

Product Specifications

Accessories And Options

The HF Series is supported by a complete line of accessories and options making filter installation and differential pressure monitoring easy.

Additional Information

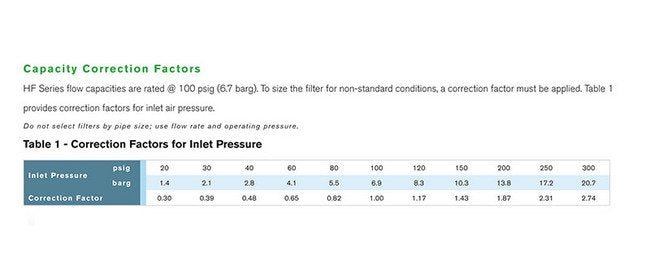

Hankison® filters remove more contaminants with less pressure drop through housings that have large flow areas. Compare the operating pressure drop of competitive brands and remember that for every extra 2 psi of pressure drop, power input needs to be increased by 1%. A systems approach has been used to allow for convenient matching of filter types to achieve the air quality you desire, while comprehensive third party testing guarantees performance to CAGI (Compressed Air And Gas Institute), ISO (International Standards Organization) and PNEUROP (European Committee of Manufacturers of Compressors, Vacuum Pumps and Pneumatic Tools) standards.With a greater selection of filter grades, more models to choose from and worldwide technical and service support, Hankison® offers a systemized solution for your compressed air quality needs.

Air Qualitypressure Drop Dry Pressure Drop

1 psid | 0.07 bar

Air Qualitypressure Drop Remaining Oil

1 ppm

Air Qualitypressure Drop Solid Particulate

1 µ

Air Qualitypressure Drop Wet Pressure Drop

2 psid | 0.14 bar

Condensate Management No Air Loss Internal Float Drain

Effectively removes condensate without loss of air.

Condensate Management No Air Loss Mechanical Drain

Reliably removes condensate without need for electricity.

Element Grades For Enhanced Performance

Grade 7 Air Line FilterProvides removal of liquid water and oilRemoves solid particulate to 1.0 micronMaximum remaining oil content (Filter efficiency has been established in accordance with CAGI standard ADF400 and is based on 100 ºF (38 ºC) inlet temperature.): 1.0 ppm w/wOperationFirst Stage - Captures larger particles with alternate layers of fiber media and screenSecond Stage - Coalesces aerosols and captures solid particles with multiple layers of epoxy bonded, blended fiber media

Engineered For Efficiency Easy To Install

Modular connections allow housings to be connected in series easily, while saving spaceWall mounting bracket optionalCan be mounted for left or right entryNew space saving design reduces service clearances

Engineered For Efficiency Easy To Maintain

1/8 turn, self-locking bayonet head to bowl connections (through 1 in.)Push on elements make element replacement quick and easyIf housing is not depressurized before disassembly, escaping air gives audible warningCaptive O-ringRibbed bowls allow use of C spannerColor coded elements for easy identification

Engineered For Efficiency Easy To Operate

Differential Pressure GaugeDifferential pressure indicatorsIndicates optimum time for element change - maximizing your element investment while minimizing pressure dropLarge, easy to read gauge faceDual faces allow housings to be mounted in any flow directionCan be mounted remotelySwitch for remote indication availableSlide indicatorChanges color when filter element requires replacementLiquid Level IndicatorAllows visual monitoring of liquid level and signals the need for preventative maintenance to avoid downstream contaminationManufactured from thermoset polyurethane, compatible with synthetic lubricantsInternal Automatic DrainsPilot operated, pneumatically actuated to reliably discharge collected liquidViton seals - compatible with synthetic lubricantsInlet screen for additional protectionDischarge fitting threaded to facilitate drain line connection

Engineered For Efficiency Modular Housings For Flows Through 780

Manufactured from top quality aluminum, zinc and steelChromated and epoxy powder painted (interior and exterior) for added durability and corrosion resistance300 psig (21 bar) maximum working pressure (tested to a 5:1 safety factor)

Features

Withstands temperatures to 150 ºF (66 ºC)Push-on elements provide simple replacementPiston type seal keeps unfiltered air from by-passing elementStainless steel, corrosion resistant inner and outer coresLow resistance to flowSeam welded durabilityMatrix blended fiber mediaLarge, effective surface area ensures high efficiencies and minimizes pressure dropCoated, closed cell foam sleeveResists chemical attack from oils and acidsEnsures high efficiencies by preventing re-entrainment of coalesced liquidsChemically resistant end capsSilicone free

Note

Time-based Filter Monitor recommended.

Pressure Monitoring Differential Pressure Slide Indicator

Color indicator moves based on differential pressure.

Pressure Monitoring Electronic Filter Monitor

Predicts the optimal time to change the element.

Quality Compressed Air

A typical compressed air system is contaminated with abrasive solid particles such as dust, dirt, rust and scale, compressor lubricants (mineral or synthetic), condensed water droplets and acidic condensates and oil and hydrocarbon vapors.If not removed, these contaminants increase pneumatic equipment maintenance costs, lead to instrument and control failure, contribute to poor product fit and finish, and contaminate processes.The right Hankison® filter or filter system will remove these contaminants allowing your compressed air system to deliver the quality of air required by your application - whether it's plant air, instrument air, medical air or helping to ensure consistent output quality while minimizing operating costs.

Specifications Connection Size

3/8 in | 1/2 in

Specifications Connection Type

NPT

Specifications Flow Capacity At 100 Psig 67 Bar Pressure

20 scfm | 34 nm³/h

Specifications Height

8 in

Specifications Model

Modular Type Housings

Specifications Modular Housing Material

Aluminum | Steel | Zinc

Specifications Options

D (Internal Automatic Drain) | M (Electronic Filter Monitor) | P (Differential Pressure Slide Indicator) | T (Drain Plug) | X (External Drain Adapter)

Specifications Quantity

1

Specifications Replacement Element Model

E 7-12

Specifications Series

HF

Specifications Weight

4.2 lb

Specifications Width

4 in

Technical Specifications Maximum Operating Pressure Drain Plug

300 psig | 20.7 bar

Technical Specifications Maximum Operating Pressure Internal Aut

250 psig | 17.2 bar

Technical Specifications Maximum Operating Temperature Drain Plu

150 ºF | 66 ºC

Technical Specifications Maximum Operating Temperature Internal

150 ºF | 66 ºC

Technical Specifications Minimum Operating Temperature Drain Plu

35 ºF | 2 ºC

Technical Specifications Minimum Operating Temperature Internal

35 ºF | 2 ºC

Total System Protection Element Grade

Grade 7

Total System Protection Iso Performance Data

Removes solids 1.0 micron and larger.Remaining oil content 1.0 ppm/w.ISO 8573.1:2010 Quality Class:Solid Particles - Class 2.Remaining Oil Content: Class 4.

Total System Protection Where Applied

Upstream of ultrahigh efficiency oil removal filters.At point-of-use if aftercooler/separator installed upstream.